Closed type constant-temperature drying equipment

A constant temperature drying and closed technology, applied in the direction of biomass drying, drying solid materials, drying chamber/container, etc., can solve the problems of damage to the protoplasmic structure of embryogenic cells, great influence on seed activity, and shorten the storage life of seeds, etc., to achieve Good temperature control effect, excellent energy efficiency ratio, fluorine-free safe and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

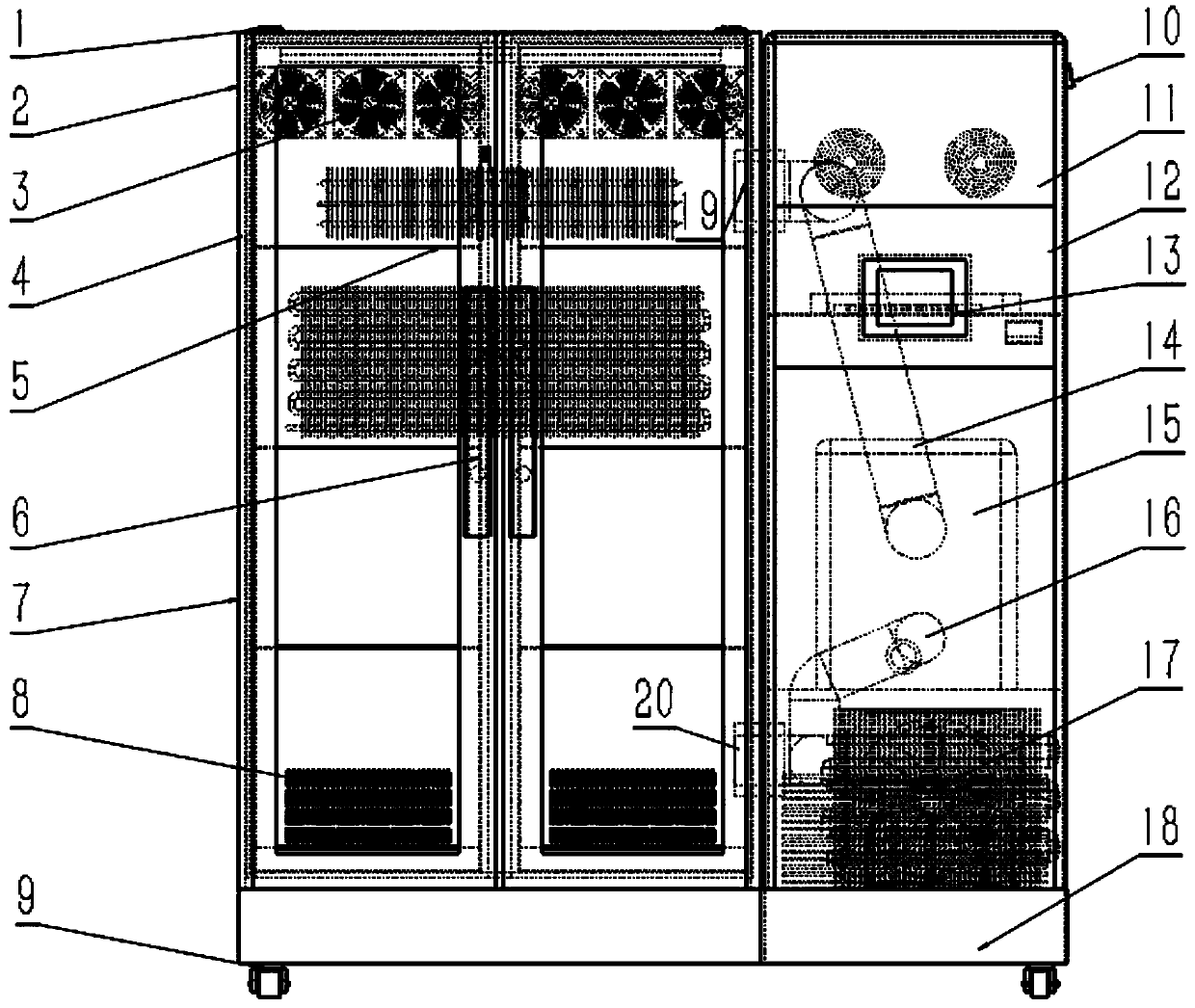

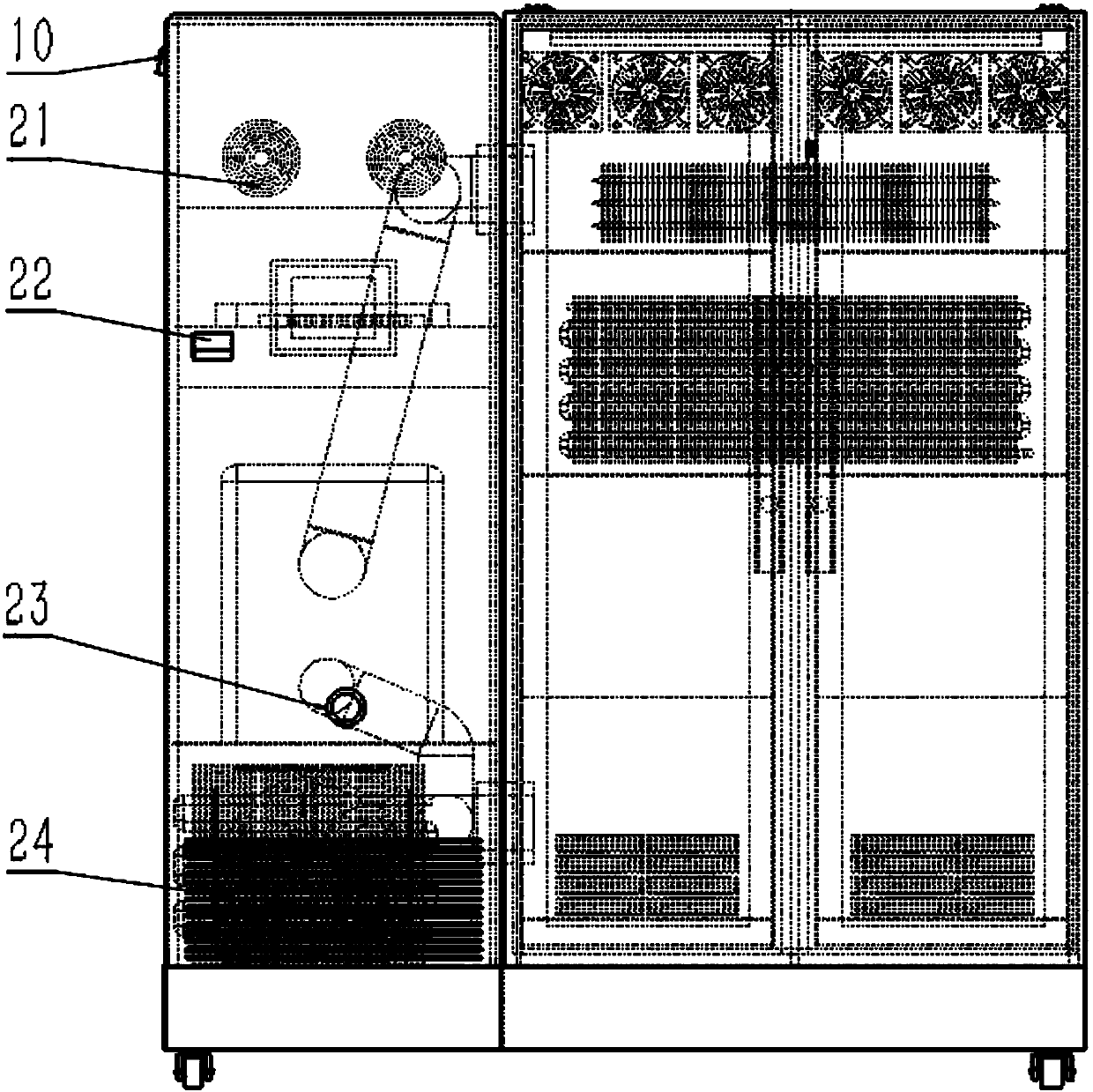

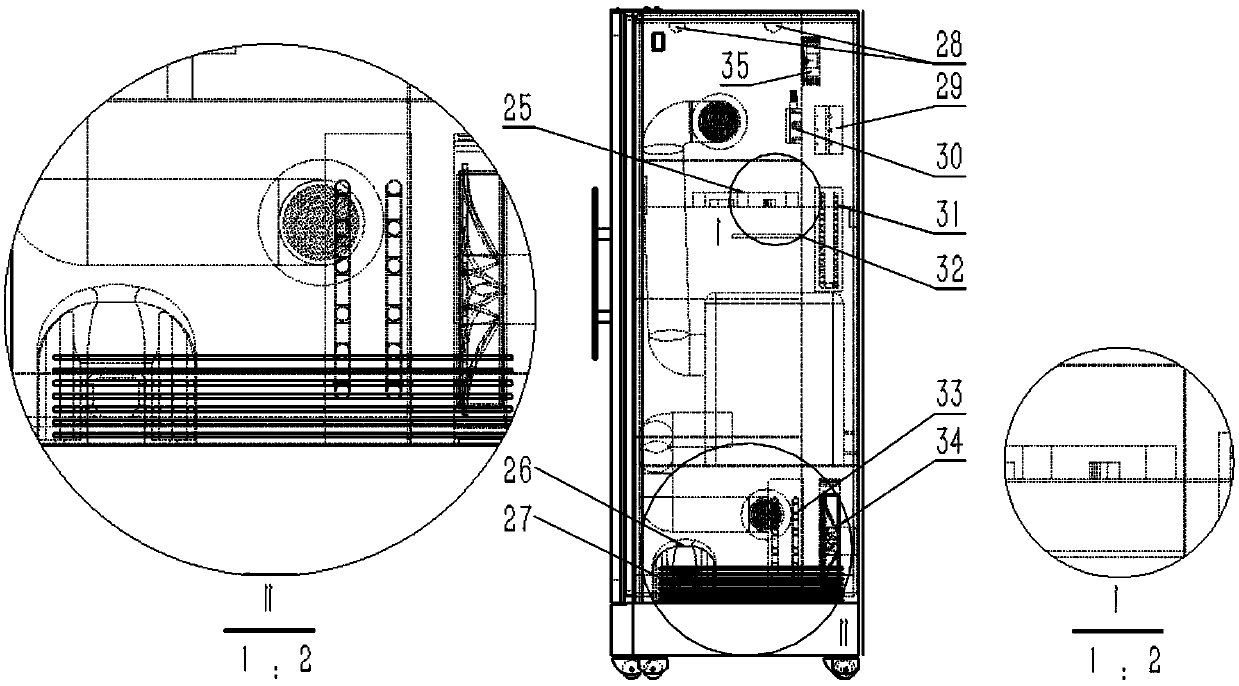

[0035] Such as Figure 1-4 As shown, the present invention provides a closed constant temperature drying equipment, including a drying chamber 2 and a control chamber 11 . The drying chamber 2 is used to place items to be dried; the drying chamber 2 is provided with two doors 4, which are double door structures, and the door body 4 is surrounded by a hollow steel structure, and the middle part of the door body 4 is double-layer vacuum tempered Glass structure, the connection between the door body 4 and the drying room 2 cabinet and the connection between the two door bodies 4 is provided with a sealing structure 7, and is equipped with a locking device to prevent humid and high temperature air from entering the drying room. Room 2. The sealing structure 7 is a multi-layer magnetic sealing rubber ring, which can fully seal the connection between the door body 4 and the drying room 2 cabinet and the connection between the two door bodies 4; A rotary hinge 1 is also provided at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com