Visual defect detection method and system based on intelligent mobile terminal

A technology for intelligent mobile terminals and visual defects, applied in signal transmission systems, optical test defects/defects, instruments, etc., can solve problems such as difficult to meet production needs, expensive, cumbersome development process, etc., to achieve network communication and Group control, high utilization rate of equipment, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

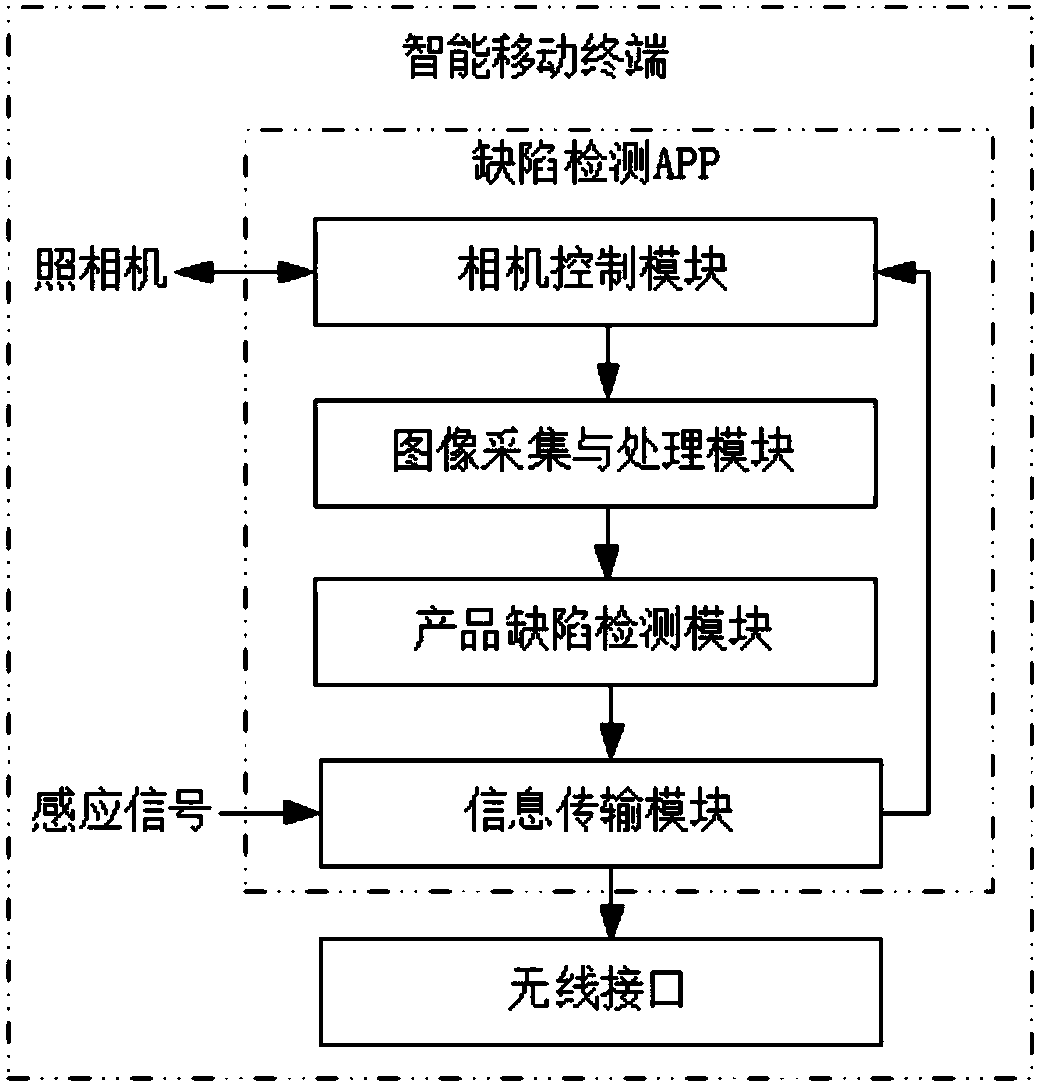

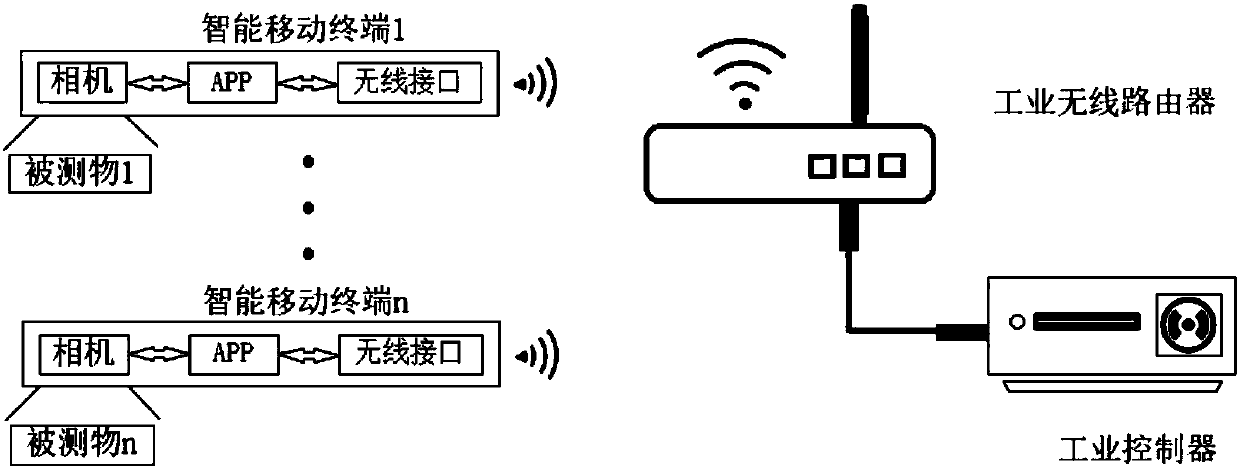

[0029] Refer to attached figure 1 Specifically explaining this embodiment, for the same type of defect, the detection method is the same, that is, the same APP can be used for different defects of the same type of product. This type of visual defect detection system based on intelligent mobile terminals includes: intelligent mobile terminals with camera functions and wireless interfaces, routers, and industrial controllers.

[0030] Install the written defect detection APP in the smartphone, that is, embed the intelligent detection system in the smartphone. The intelligent detection system mainly includes: image acquisition and processing module, product defect detection module, and information transmission module.

[0031] Adjust and fix the position of the smartphone for testing, and use the smartphone’s built-in camera to take pictures of qualified standard samples in the testing environment where the position is located, and obtain sample images of qualified products. Sel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com