Raw silk defect detection equipment

A technology for detecting equipment and defects, applied in measuring devices, material analysis through optical means, instruments, etc., can solve the problems of high requirements for image acquisition equipment and image processing equipment, cumbersome preparation work, and no classification of raw silk defects. Low personnel requirements, fast image processing speed, avoiding the effect of high equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

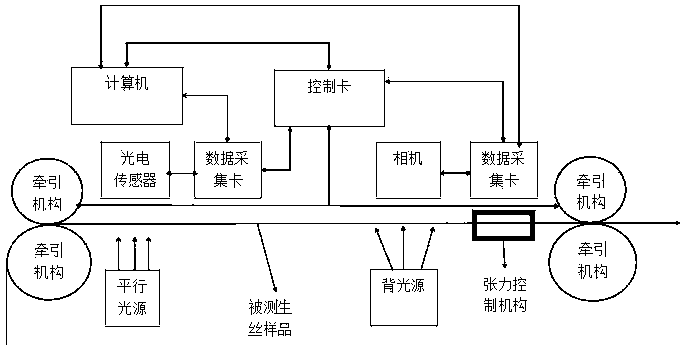

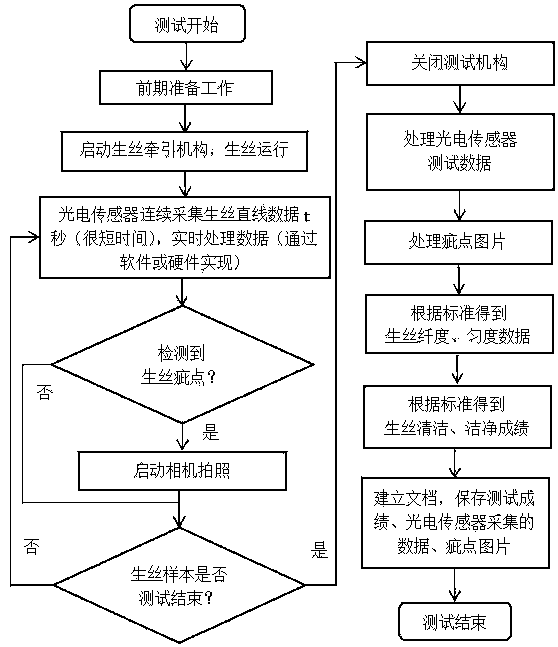

[0020]A raw silk defect detection device. An analog photoelectric sensor and a camera are installed on the near side of the raw silk traction path. The analog photoelectric sensor continuously tests a single thread to find defects, determine the location of the defects, and initially determine the size and type of the defects; The analog photoelectric sensor is connected with the first data acquisition card, and the data is transmitted to the first data acquisition card, and the first data acquisition card is connected with the computer and the control card; the camera is connected with the second data acquisition card, and the data is transmitted to the second data acquisition card. Acquisition card, the second data acquisition card is connected with the computer and the control card; after the analog photoelectric sensor detects the defect, the camera is triggered by the control card to take pictures of the defect, and the defect image is processed by the computer to determine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com