Constant-pressure self-circulation frost heaving test system

A frost heave test and self-circulation technology, applied in the direction of material thermal expansion coefficient, etc., can solve problems such as inability to use test simulation, long test period, and test result influence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

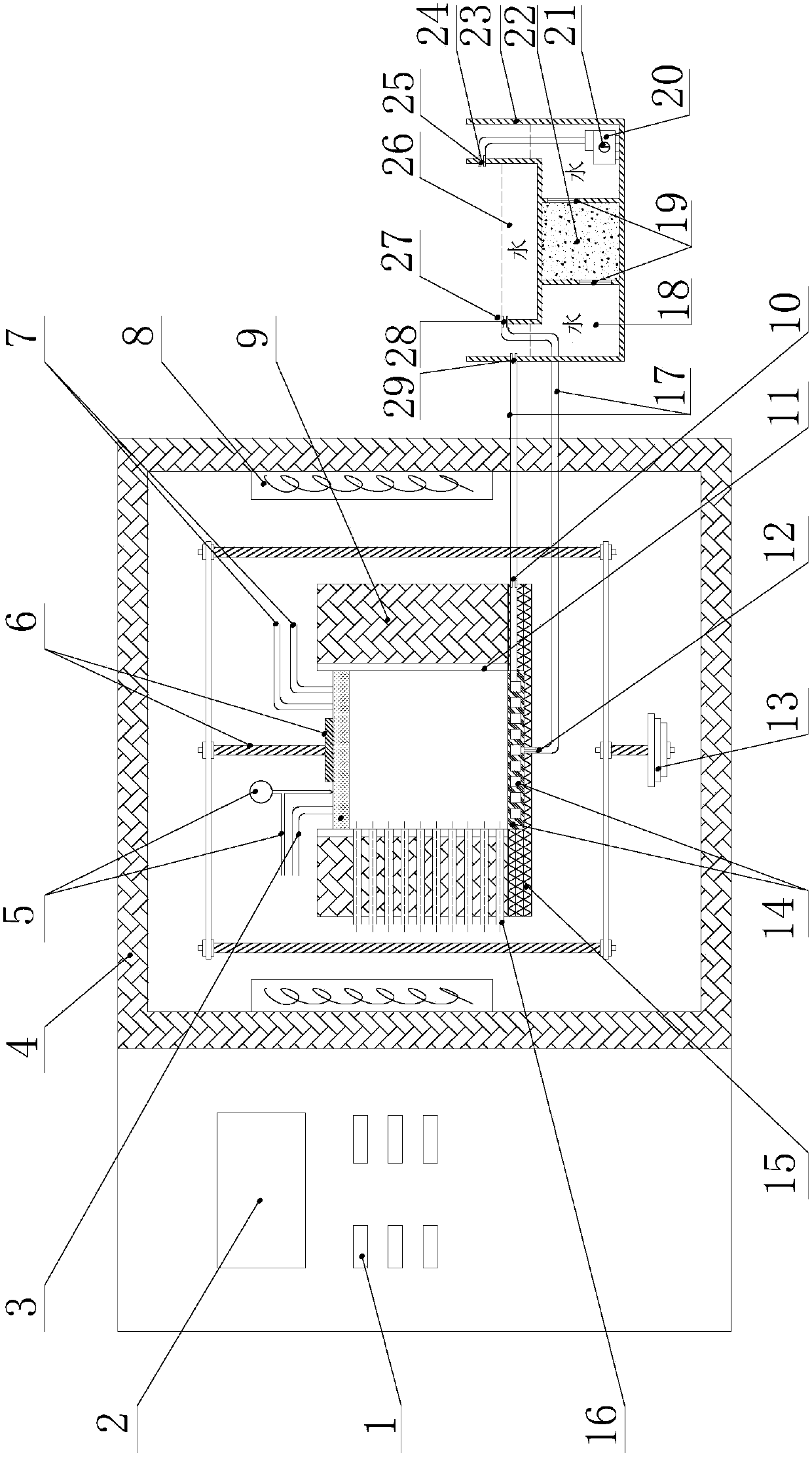

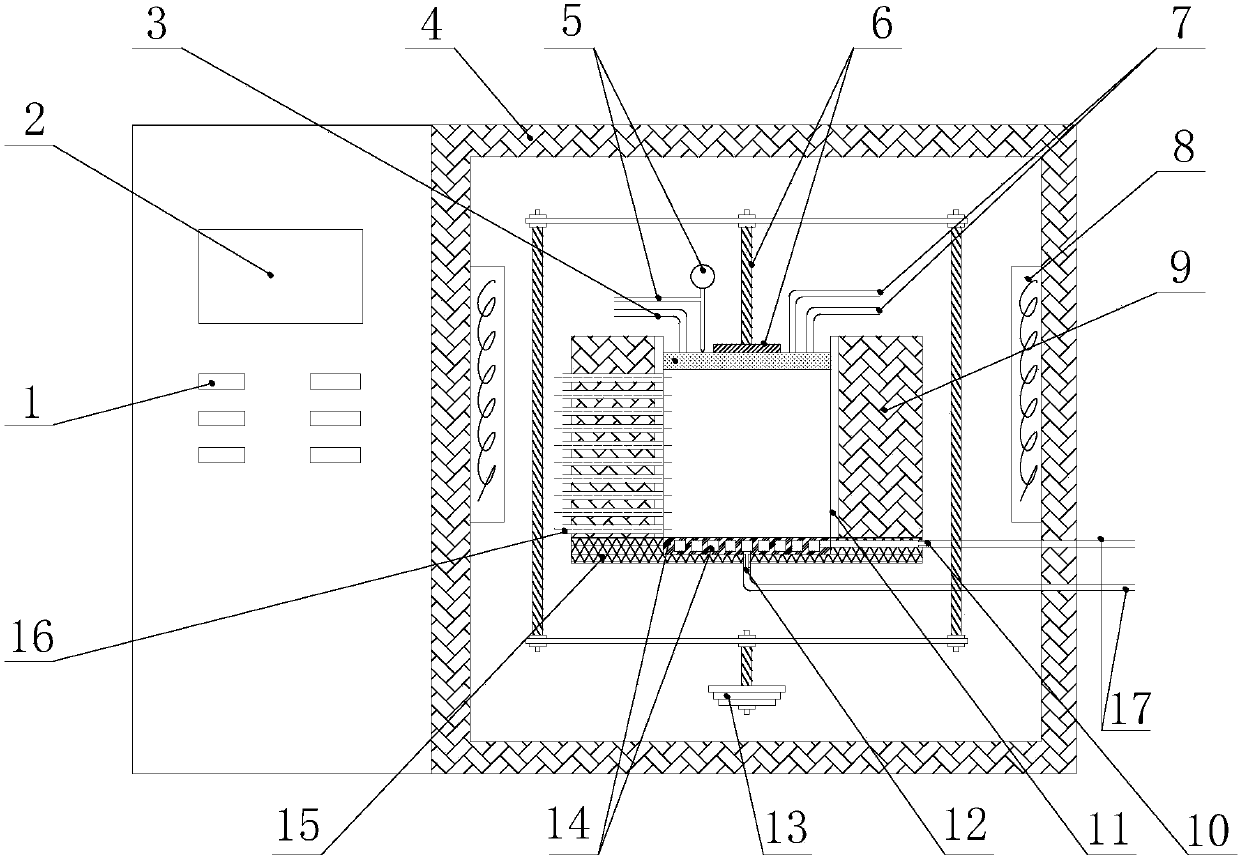

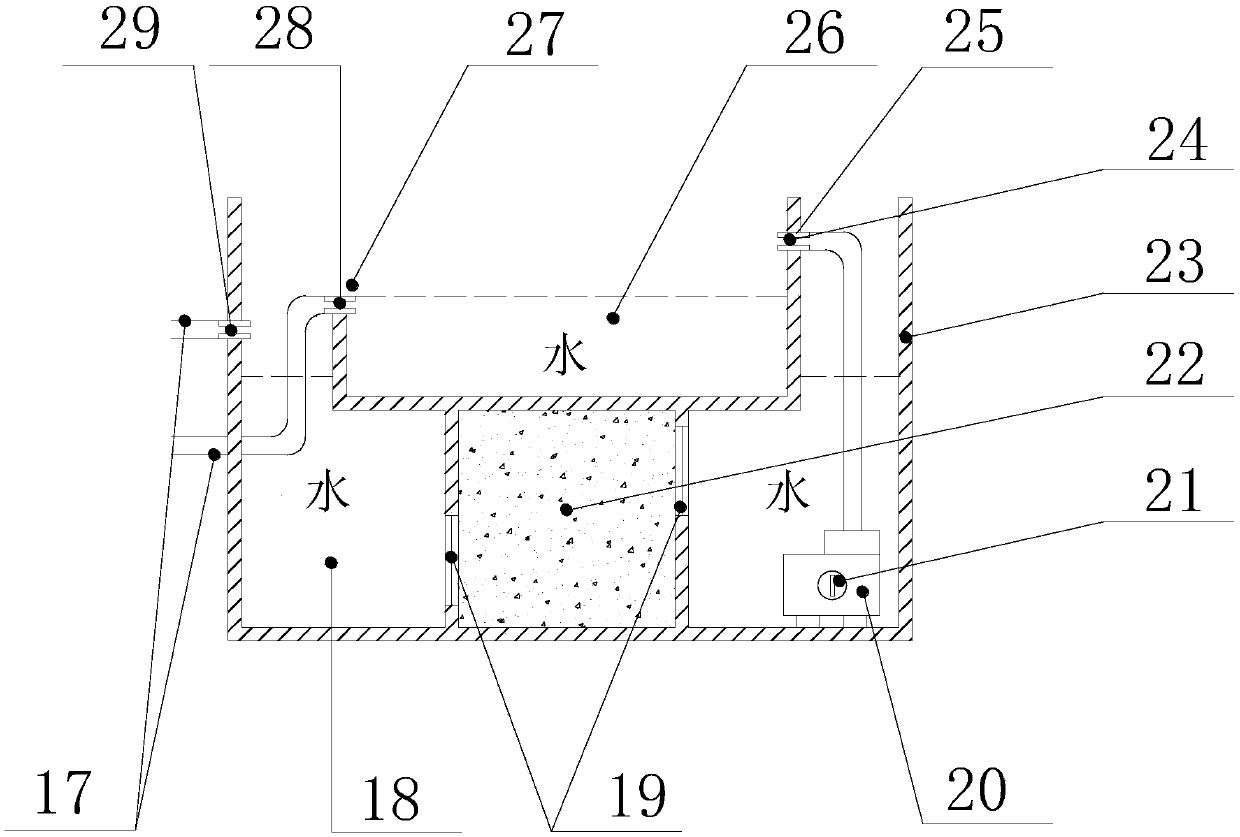

[0019] refer to Figure 1 to Figure 3 , the constant pressure self-circulation frost heave test system includes a frost heave test subsystem and a water pressure control subsystem. The frost heaving test sub-system includes a test box 4 with thermal insulation material, and also includes a controller module 1, which is arranged outside the test box 4 and installed together with the test box 4. The controller module 1 is provided with buttons and a display device 2 .

[0020] A vertically arranged columnar transparent sample box 11 (square column or cylindrical shape) is arranged in the test box body 4 , and an insulating material 9 is arranged outside the sample box 11 . The top surface of the sample box 11 can move up and down, and the bottom surface of the sample box 11 is a backing plate 14 with holes with a certain thickness. A soil sample is placed in the sample box 11, and a layer of wet filter paper is laid on the top and bottom of the soil sample. The test chamber 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com