Method and system based on laser point heat source to measure thermophysical parameters of solid material

A technology of thermophysical parameters and solid materials, applied in the direction of material thermal development, etc., can solve problems such as surface area calculation errors, laser heating power conversion effects, and higher requirements for the surface flatness of test pieces, so as to achieve accurate estimation and avoid errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

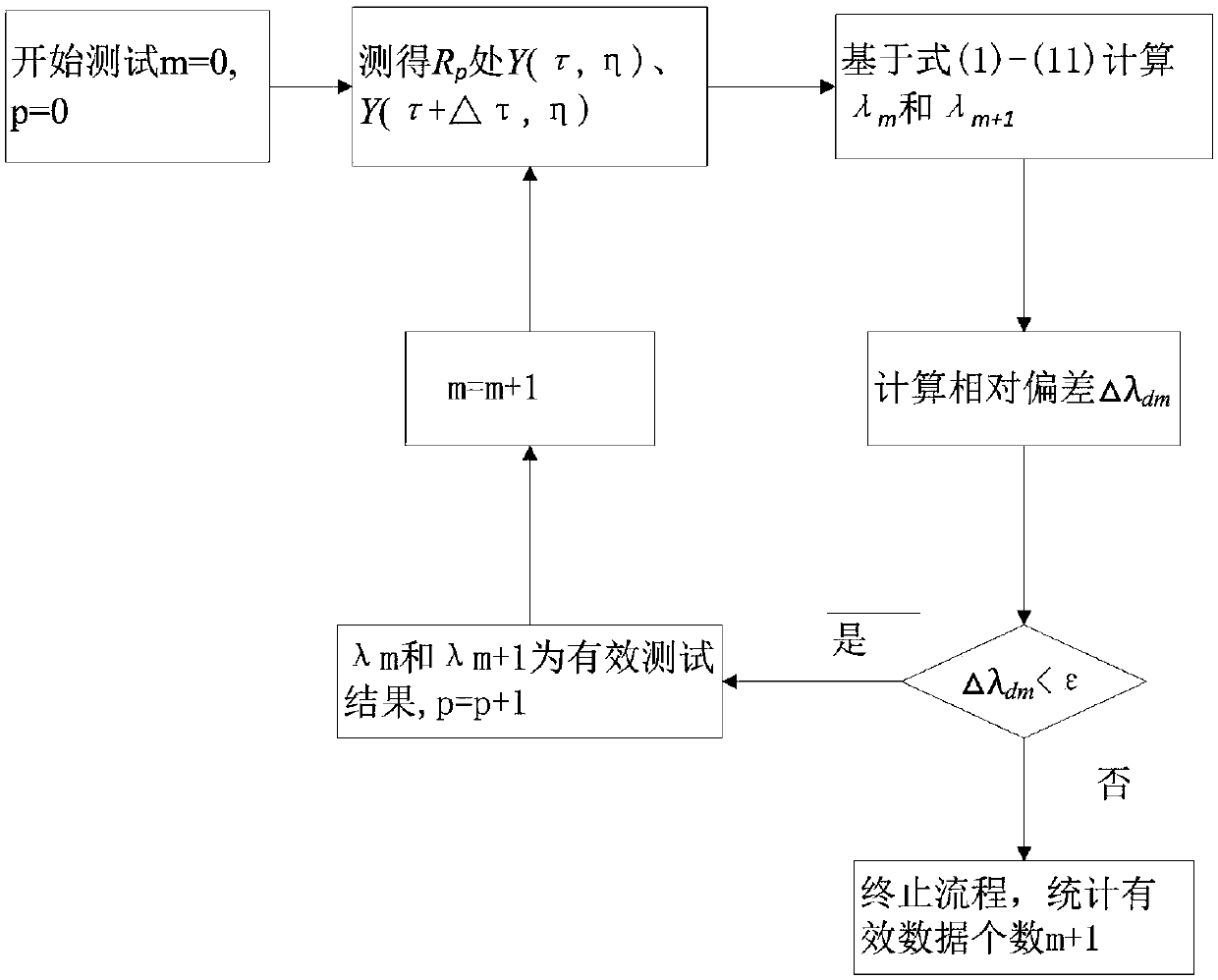

Method used

Image

Examples

Embodiment

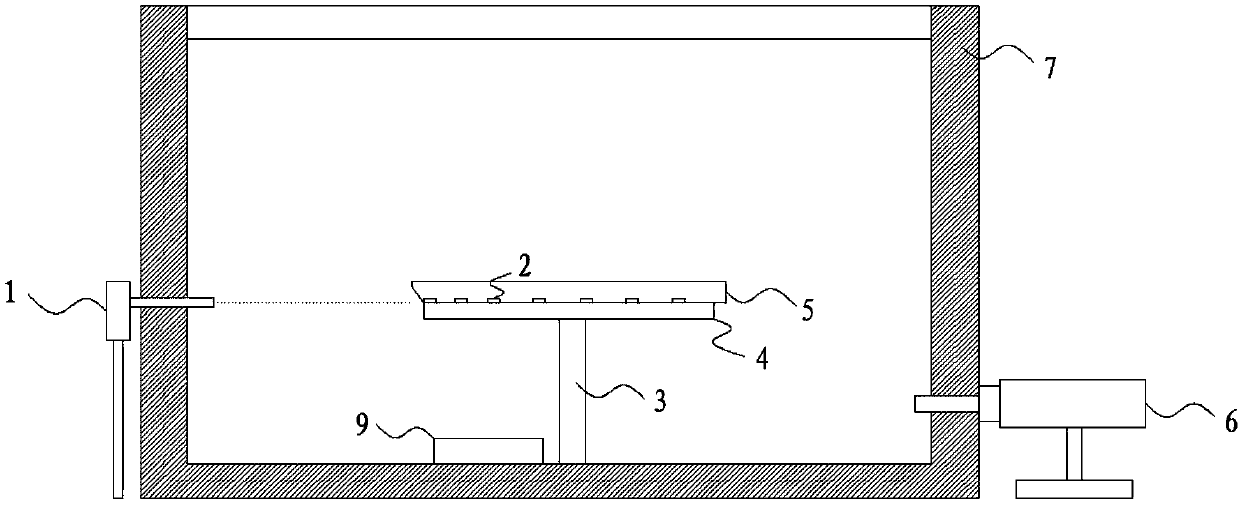

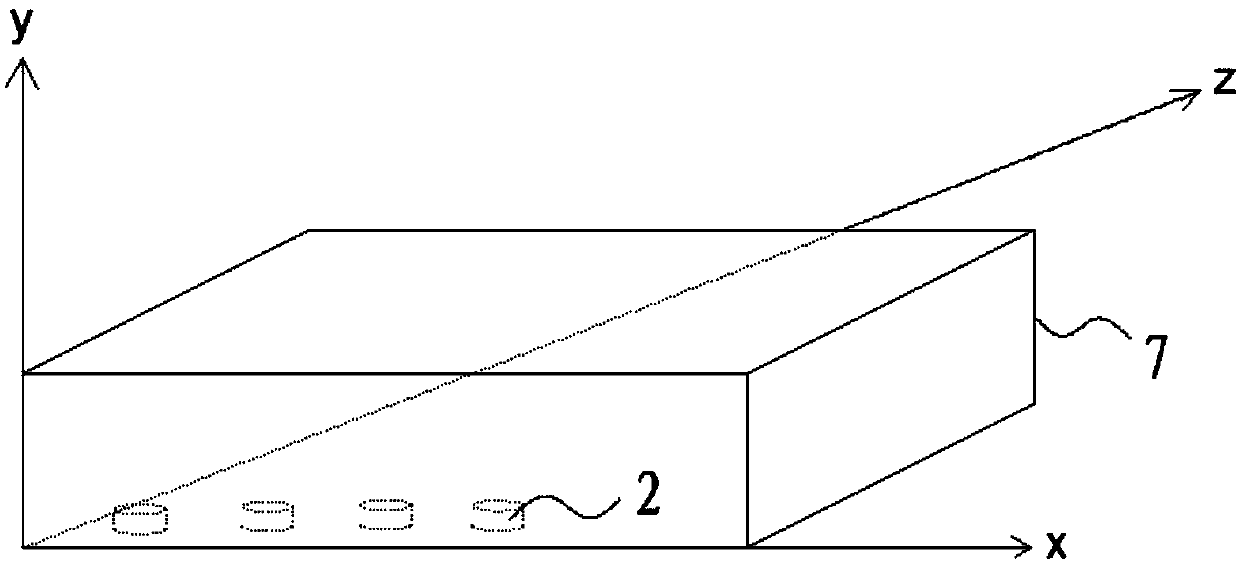

[0038] A system for measuring thermal and physical parameters of solid materials, including a laser transmitter 1, a vacuum box 7, a vacuum pump 6, a barometer and a data acquisition component, the barometer and the vacuum pump 6 are installed on the side of the vacuum box 7, The barometer includes a detection head and a meter head, and the detection head runs through the side of the vacuum box 7 and extends to the inner cavity of the vacuum box 7;

[0039] The upper surface of the vacuum box 7 is movably provided with end caps, and the left and right sides of the vacuum box 7 are provided with through holes. The laser transmitter 1 includes an emitting lens and the emitting lens is embedded in the through hole. In the hole, a sample 5 bracket 3 is fixedly arranged on the surface of the bottom of the inner cavity of the vacuum box 7, and a heat insulating cotton 4 is fixedly arranged on the sample 5 bracket 3, and a sample is placed on the upper surface of the heat insulating c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com