Accurate turnover device for synchronously detecting flaws of multiple tubes and turnover method thereof

A technology of turning over devices and tubes, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of low accuracy of rotation angle, inability to use forced feeding devices, industrial TV flaw detection, etc., to improve the accuracy of turning angle and realize mechanization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

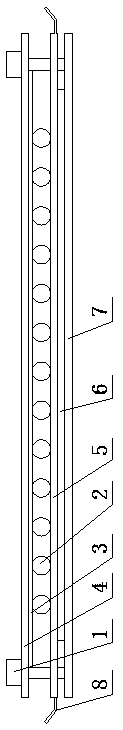

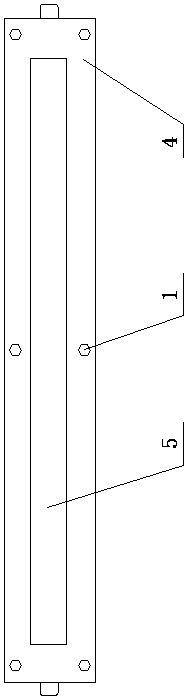

[0014] A precise overturning device for multi-piece simultaneous pipe flaw detection, which consists of: a flaw detection upper plate 4, the flaw detection upper plate is connected with a flaw detection bottom plate 7 through a screw 1, a needle bearing 6 is placed on the flaw detection bottom plate, the A pull plate 5 is placed above the needle roller bearing, a pull plate handle 8 is respectively arranged at the left and right ends of the pull plate, and a flaw detection tube 2 is placed above the described pull plate.

Embodiment 2

[0016] According to the multi-piece simultaneous pipe flaw detection precision flipping device described in Example 1, the flaw detection tubes are evenly arranged on the pull plate, and a sticky rubber 3 is placed between the flaw detection upper plate and the flaw detection tubes, The flaw detection tube is clamped by the flaw detection upper plate and the flaw detection bottom plate, a square hole 5 is opened in the middle of the flaw detection upper plate, and the flaw detection tube has welds, and the positions of all welds correspond to At the said square mouth position.

Embodiment 3

[0018] The method of overturning and flaw detection using the multi-piece simultaneous pipe flaw detection precision flipping device described in one of the embodiments 1-2, the working steps are as follows:

[0019] First, loosen the flaw detection upper plate, place the flaw detection tubes on the pull plate one by one, and keep an appropriate distance, after placing, use the screw rod to place the flaw detection upper plate It is connected and clamped with the flaw detection bottom plate; the width of the pull plate is slightly narrower than that of the flaw detection upper plate and the flaw detection bottom plate, so as to avoid collision with the bolts; the flaw detection upper plate, flaw detection bottom plate and pull plate A square hole is left in the middle of the plate to place the welding joint of the flaw detection tube at the square hole position for radiographic flaw detection; rubber is pasted on the contact position between the flaw detection upper plate and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com