Optical fiber cutter

A technology of optical fiber cutter and fiber table, which is applied in the direction of optical waveguide coupling, etc., can solve the problems of human injury, difficulty in removing pain, and broken optical fiber in the human body, so as to avoid the effect of harming the human body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings. As a limitation of the present invention.

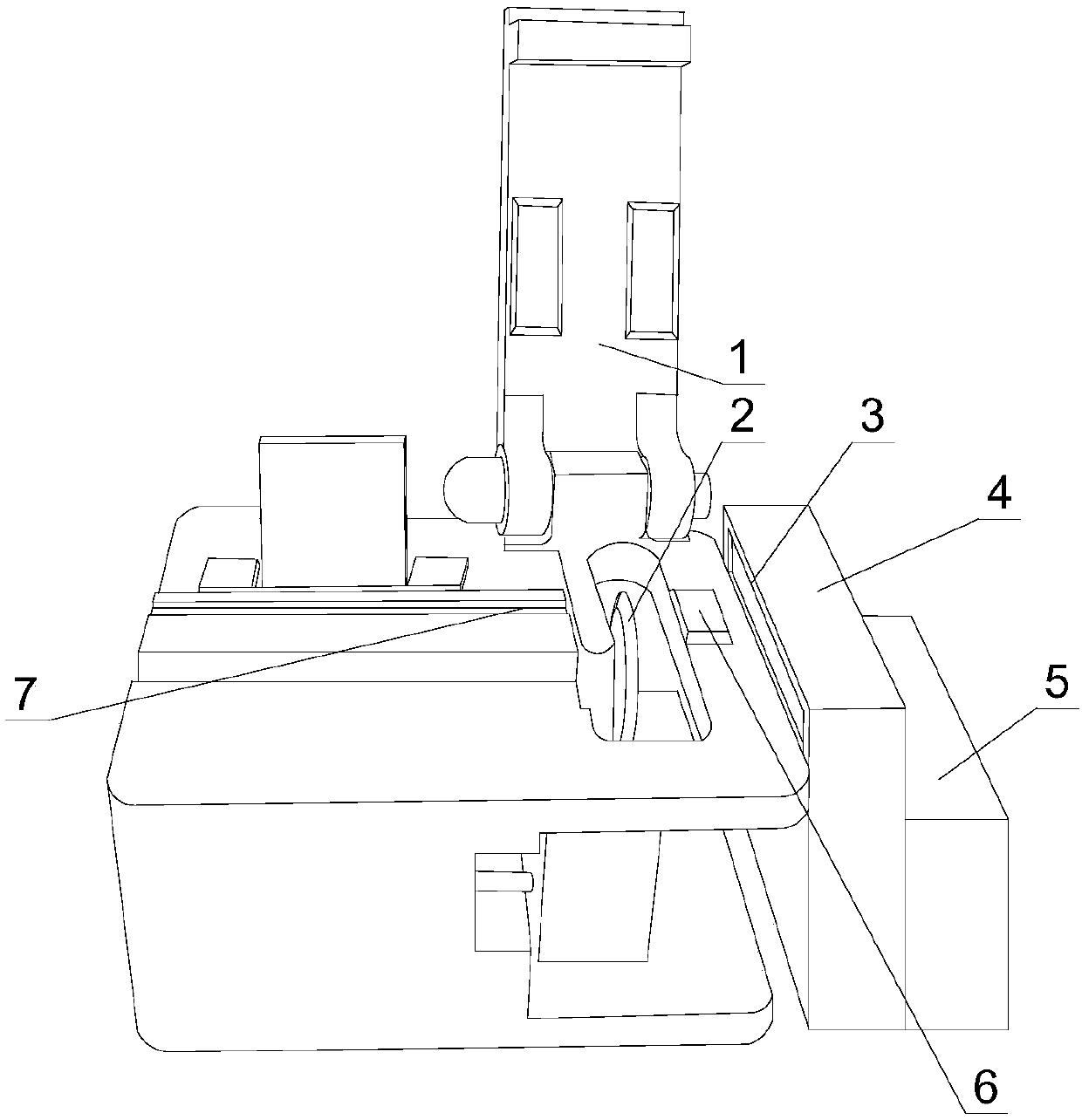

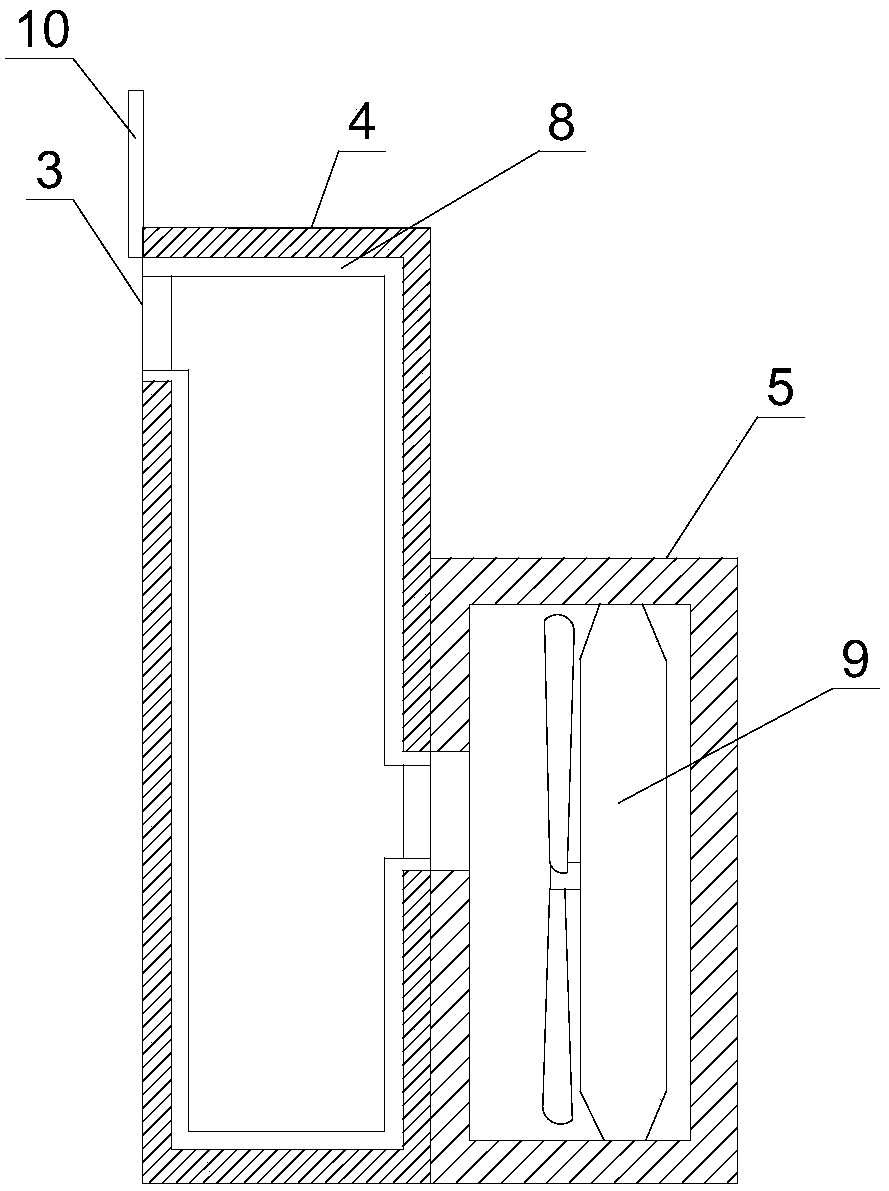

[0016] Such as Figure 1~2 As shown, an optical fiber cutter includes an optical fiber cutter, and the optical fiber cutter includes a pressing arm 1, a blade 2, a fiber pressing table 6 and a fiber-carrying groove 7, and also includes an air duct 4 and an air box 5. The duct 4 and the bellows 5 are fixed on the side of the fiber cutter, the air duct 4 is provided with an air outlet 3, and the air outlet 3 is aligned with the blade 2, the fiber press table 6 and the fiber-loading groove 7, and the bellows 5 is provided with a fan 9, the bellows 5 communicates with the air duct 4, an adhesive layer 8 is attached to the inner wall of the air duct 4, and a sliding cover 10 is provided at the air outlet 3, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com