Rectangular high-voltage electric socket connector

A technology of socket connector and high-voltage electricity, which is applied in the direction of connection, two-part connection device, and parts of the connection device. It can solve the problems of reducing production efficiency, product failure, cracking, etc., to improve production efficiency and reduce assembly time. , the effect of reducing the number of bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

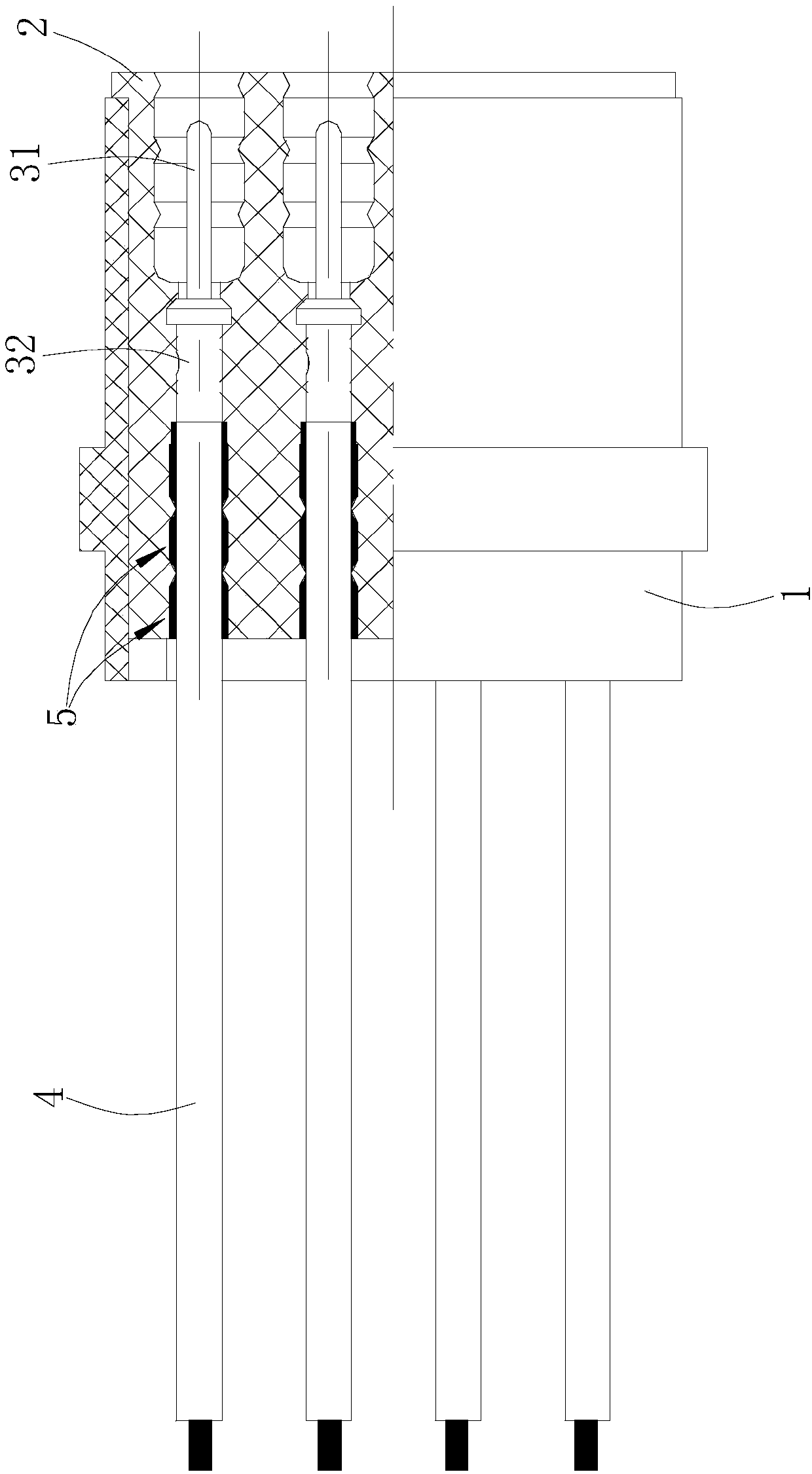

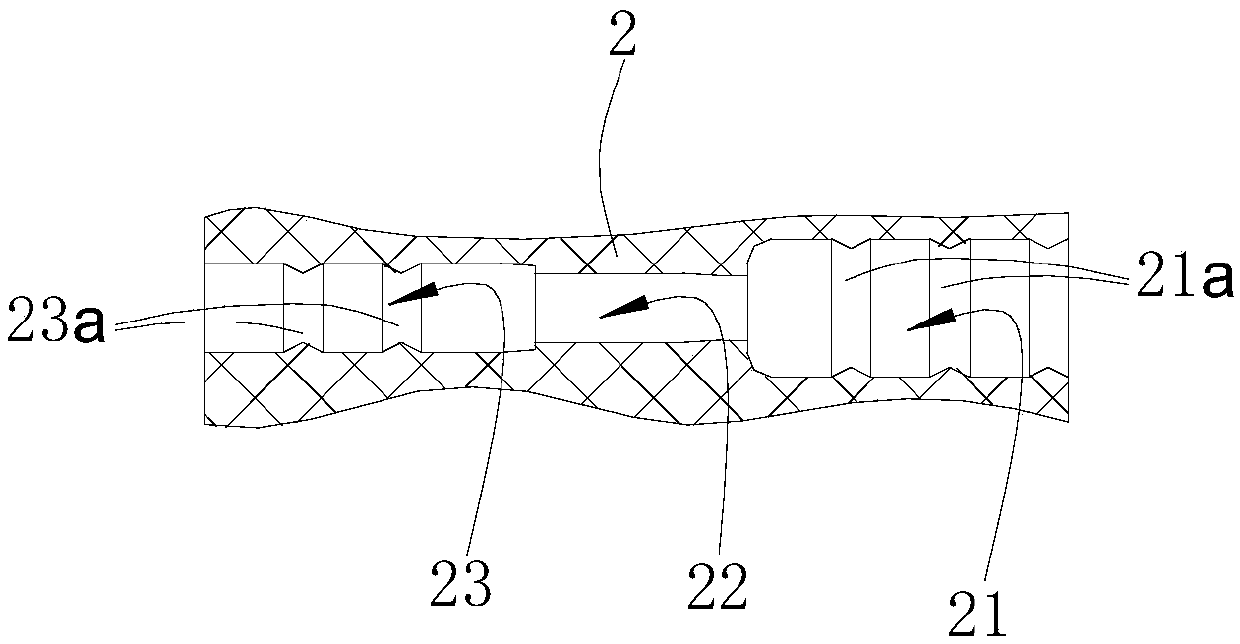

[0014] Such as Figure 1 to 2 Shown ( figure 2 Only part of the mounting plate 2 is shown in and figure 2 Only one mounting hole is shown in).

[0015] The socket connector includes a hollow socket housing 1, a mounting plate 2, and a pin assembly.

[0016] The socket shell 1 and the mounting plate 2 are manufactured by using new engineering plastics through molds. The socket shell 1 made of new engineering plastics not only has good mechanical strength and dimensional stability, but also has light weight and good environmental resistance. , High voltage strength.

[0017] The socket housing 1 is sleeved on the outside of the mounting plate 2. The mounting plate 2 has eight mounting holes penetrating its front and rear surfaces. The pin assembly includes a pin portion 31 and a connecting portion 32. The pin portion 31 and the connecting portion 32 are welded , The connecting portion 32 is connected with the high-voltage wire 4, and the pin portion 31 is made of a copper alloy wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com