Composite functional male silkworm moth powder and application thereof

A functional, male silkworm moth technology, applied in composite functional male silkworm moth powder and its application fields, can solve the problems of no obvious effect on controlling surface oil content, damage of male silkworm nutrient components, and inability to be directly applied, etc., to achieve control of surface oil production And the water yield, the effect of retaining the potency of the finished medicine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

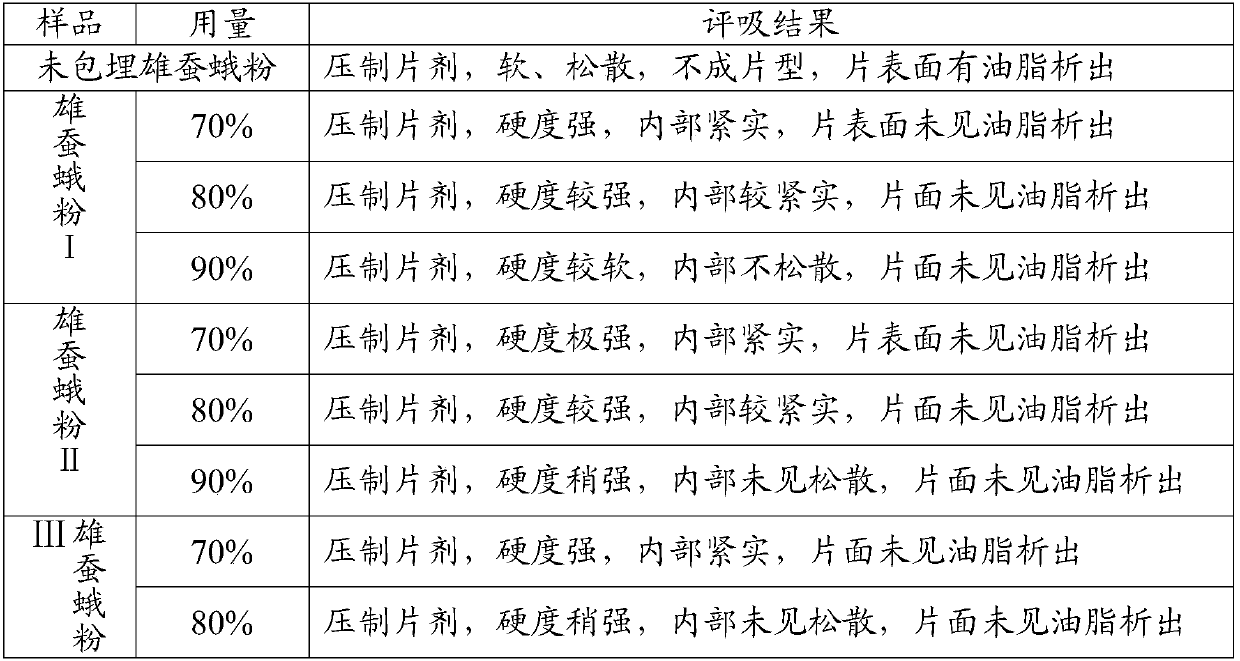

[0027] (1) Take whole fresh male silkworm moths and dry them at 55°C for 8 hours, put them into a pulverizer, set the speed at 35000r / min, pulverize them for 40s, and collect the male silkworm moth paste.

[0028] (2) Get creamy male silk moth 59.5g and put into a beaker, add sheep testosterone peptide, bullwhip peptide, oyster peptide altogether 40g (wherein the addition ratio of the weight of sheep testosterone peptide, bullwhip peptide and oyster peptide is 1:1: 1), after uniformly mixing 0.5g of glyceryl mono and distearate, add 147.5g of pure water, 2.5g of glucose syrup, stir evenly, pour into the colloid mill, speed 2800r / min, emulsification time 30min, emulsification fineness 200 mesh. The resulting mixed solution is passed through a homogenizer, set at a rotating speed of 15000r / min, and homogenized for 10min to obtain a suspension of male silkworm moths;

[0029] Among them, the glucose syrup was purchased from Shanghai Haocheng Food Development Co., Ltd., and the p...

Embodiment 2

[0032] (1) Take whole fresh male silkworm moths and dry them at 60°C for 7 hours, put them into a grinder, set the speed at 35000r / min, grind them for 30s, and collect the male silkworm moth paste.

[0033] (2) Get creamy male silk moth 8.5g and put into beaker, add sheep testosterone peptide, bullwhip peptide, oyster peptide altogether 90g (wherein the addition ratio of the weight of sheep testosterone peptide, bullwhip peptide and oyster peptide is 1:1: 1), after uniformly mixing 1.5g of glyceryl mono and distearate, add 385g of purified water, 15g of glucose syrup, stir evenly, pour into the colloid mill, set the speed at 2800r / min, emulsification time 35min, emulsification fineness 250 mesh, the resulting mixed solution is passed through a homogenizer, the set speed is 17000r / min, homogenized for 8min, and the male silkworm moth suspension is obtained;

[0034] Among them, glucose syrup was purchased from Shanghai Haocheng Food Development Co., Ltd., and the purchasing sta...

Embodiment 3

[0037] (1) Take whole fresh male silkworm moths and dry them at a low temperature of 65°C for 6 hours, put them into a pulverizer at 35000r / min, grind them for 20s, and collect all the male silkworm moths in paste form.

[0038] (2) Get creamy male silk moth 40g and put into beaker, add sheep testosterone peptide, bullwhip peptide, oyster peptide altogether 59.25g (wherein the addition ratio of the weight of sheep testosterone peptide, bullwhip peptide and oyster peptide is 1:1: 1), 0.75g of glyceryl mono and distearate, add 226.7g of purified water, 6.6g of glucose syrup, stir evenly, pour into the colloid mill, set the speed at 2800r / min, emulsification time 40min, emulsification fineness 300 The resulting mixed solution is passed through a homogenizer, set at a rotating speed of 20000r / min, and homogenized for 6min to obtain a suspension of the male silkworm moth;

[0039] Among them, glucose syrup was purchased from Shanghai Haocheng Food Development Co., Ltd., and the pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com