Microemulsion preparation method

A technology of microemulsions and preparation methods, applied in chemical instruments and methods, dissolution, chemical/physical processes, etc., can solve the problems of time-consuming, complex selection and design of microemulsions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

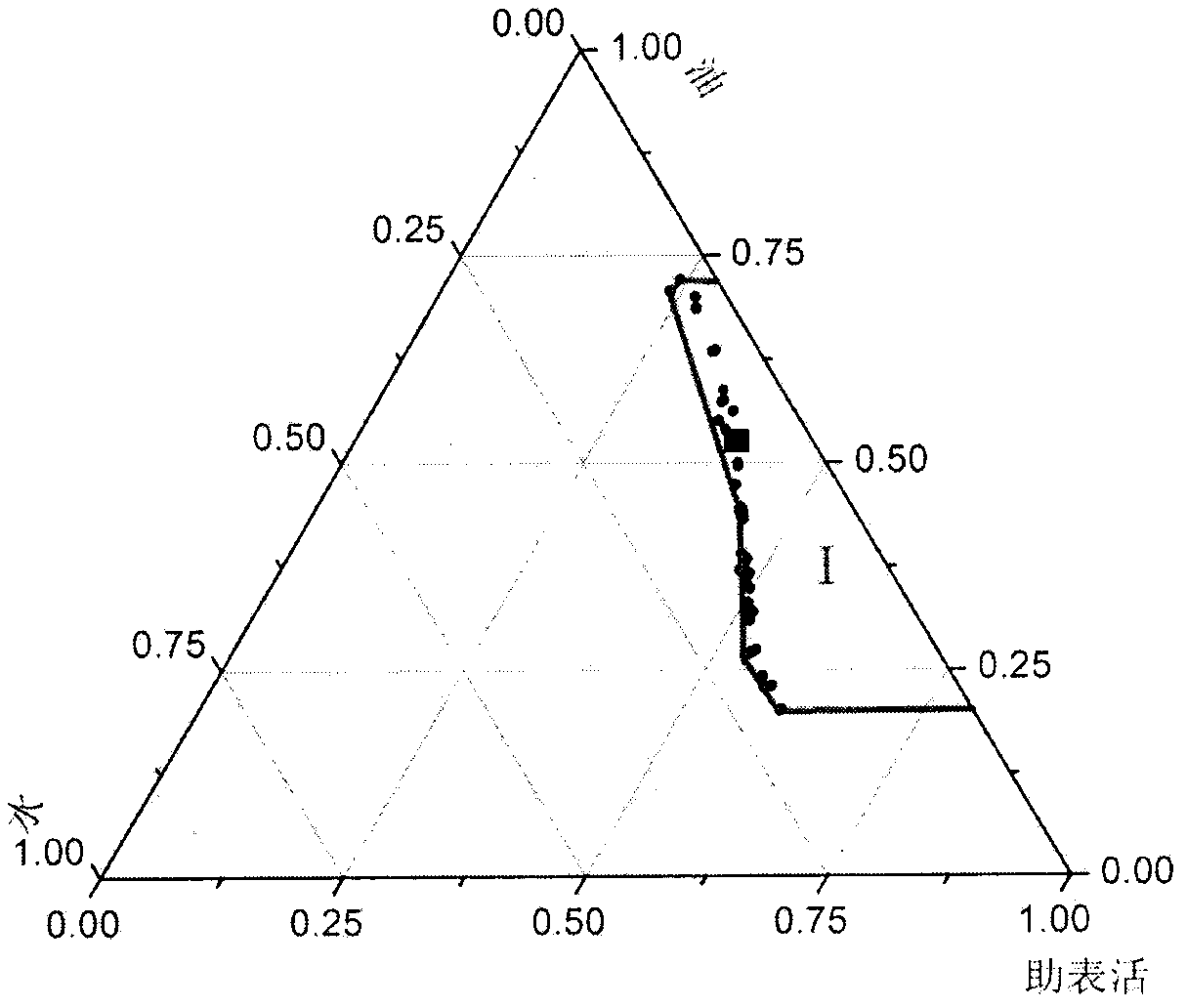

Embodiment 1

[0016] 1. At room temperature, weigh 2.037g of the surfactant Span-80, 6.004g of the co-surfactant isopropanol, and 8.072g of the oil phase cyclohexane into beaker 1, add a magnet and stir;

[0017] 2. Take another clean beaker 2, pour deionized water into it, weigh the total weight of beaker 2 and deionized water, and record the weight value as m 1 =135.761g;

[0018] 3. Use a dropper to take the deionized water in beaker 2, and add it drop by drop to beaker 1. The solution will become cloudy when the deionized water is added, and it will become transparent immediately with stirring; when the deionized water is dropped, The stirring solution cannot become transparent immediately. After standing still for 30 minutes, the liquid becomes clear again. Then add 0.05 mL of deionized water dropwise and let it stand for 30 minutes. Clarify, stop dripping deionized water, and weigh the weight of beaker 2 at this time, record it as m 2 =134.580g;

[0019] 4. At this time, the maximu...

Embodiment 2

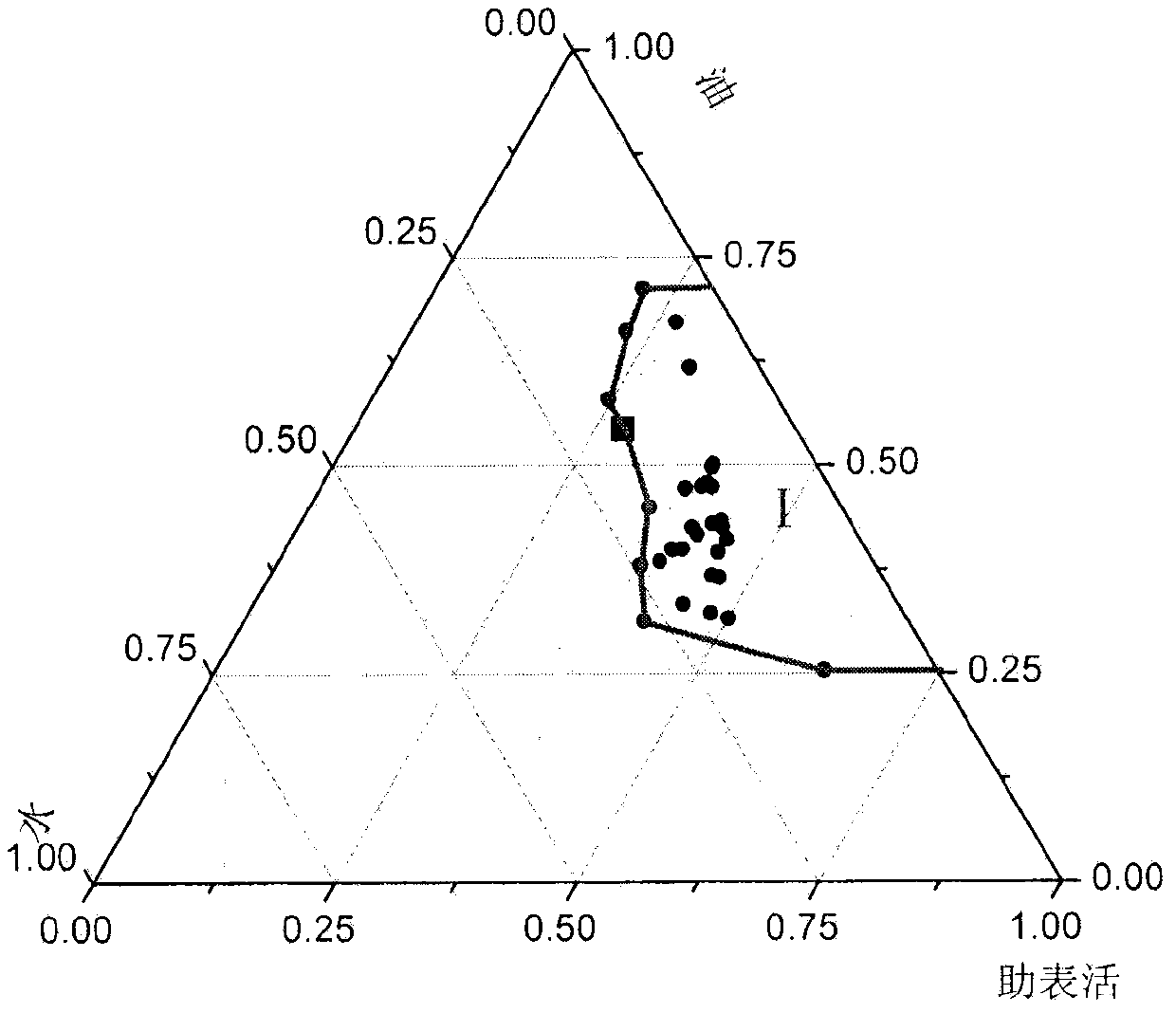

[0026] 1. At room temperature, weigh 2.033g of OP-10 surfactant, 2.091g of co-surfactant isopropanol, and 4.045g of oil phase cyclohexane into beaker 1, add a magnet and stir;

[0027] 2. Take another clean beaker 2, pour deionized water into it, weigh the total weight of beaker 2 and deionized water, and record the weight value as m 1 =112.021g;

[0028] 3. Use a dropper to take the deionized water in beaker 2, and add it drop by drop to beaker 1. The solution will become cloudy when the deionized water is added, and it will become transparent immediately with stirring; until the deionized water is dropped, The stirred solution cannot become transparent immediately. After standing still for 30 minutes, the liquid becomes clear again, and then add 0.05 mL of deionized water dropwise. If the liquid does not return to clear after standing for 30 minutes, stop adding deionized water, and weigh the weight of beaker 2, record for m 2 =110.715g;

[0029] 4. At this time, the maxi...

Embodiment 3

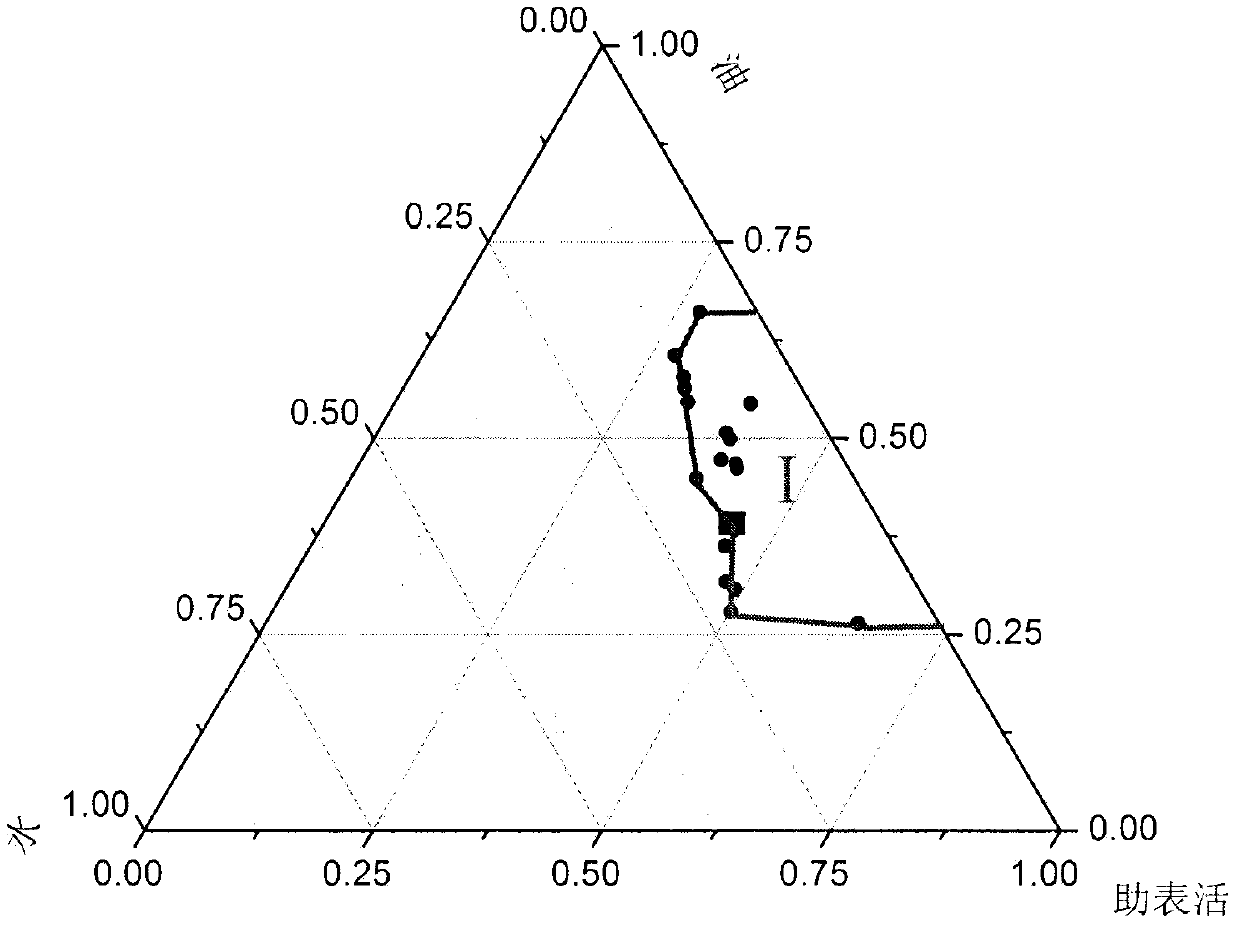

[0036] 1. At room temperature, weigh 2.032g of the surfactant Triton X-114, 14.031g of the co-surfactant isopropanol, and 12.005g of the oil phase cyclohexane into the beaker 1, add a magnet and stir;

[0037] 2. Take another clean beaker 2, pour deionized water into it, weigh the total weight of beaker 2 and deionized water, and record the weight value as m 1 =84.488g;

[0038] 3. Use a dropper to take the deionized water in beaker 2, and add it drop by drop to beaker 1. The solution will become cloudy when the deionized water is added, and it will become transparent immediately with stirring; until the deionized water is dropped, The stirring solution cannot become transparent immediately. After standing for 30 minutes, the liquid becomes clear again. Add 0.05 mL of deionized water dropwise. If the liquid does not return to clear after standing for 30 minutes, stop adding deionized water and weigh the weight of beaker 2 at this time. , denoted as m 2 =79.479g;

[0039] 4....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com