Metal attractive-core plate

A metal plate and core plate technology, applied in metal layered products, building components, sound insulation, etc., can solve the problems of general strength of composite plates, affect the use effect, poor comprehensive functions, etc., and achieve novel structural design, high strength, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

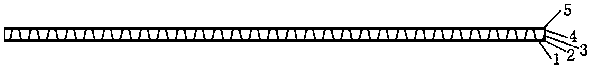

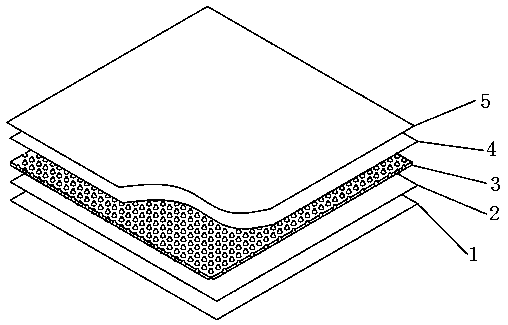

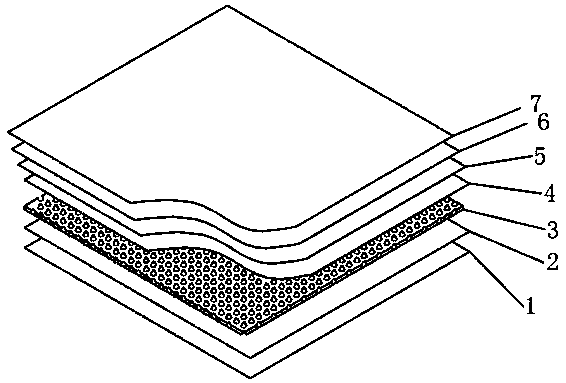

[0020] Such as figure 1 and figure 2 Shown is the first embodiment of the present invention, that is, a metal core board, including the bottom layer 1, the first polymer film layer 2, the core board layer 3, the second polymer film layer 4 and the surface layer 5 arranged in sequence , the bottom layer 1 and the surface layer 5 are all made of metal plates, the metal plates are preferably aluminum plates, steel plates, copper plates or stainless steel plates, and the first polymer film layer 2 and the second polymer film layer 4 are all made of polymer films. The polymer film is composited on both sides of the Maxim board layer 3 respectively by hot pressing. The polymer film is heated to make the adjacent layers bond. The Maxim board layer 3 can be made of aluminum core board, steel core board, copper core board or stainless steel. core board. The temperature range of hot pressing is 110-130°C, preferably 120°C.

[0021] Such as figure 1 As shown, in the present embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com