Tablet material-distributing and sealing blister packaging machine

A blister packaging machine and blister packaging technology, which are applied in the directions of packaging, transportation and packaging, packaging/bundling items, etc., can solve the problems of low packaging efficiency and insufficient hygiene, and achieve the effect of good cloth effect and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

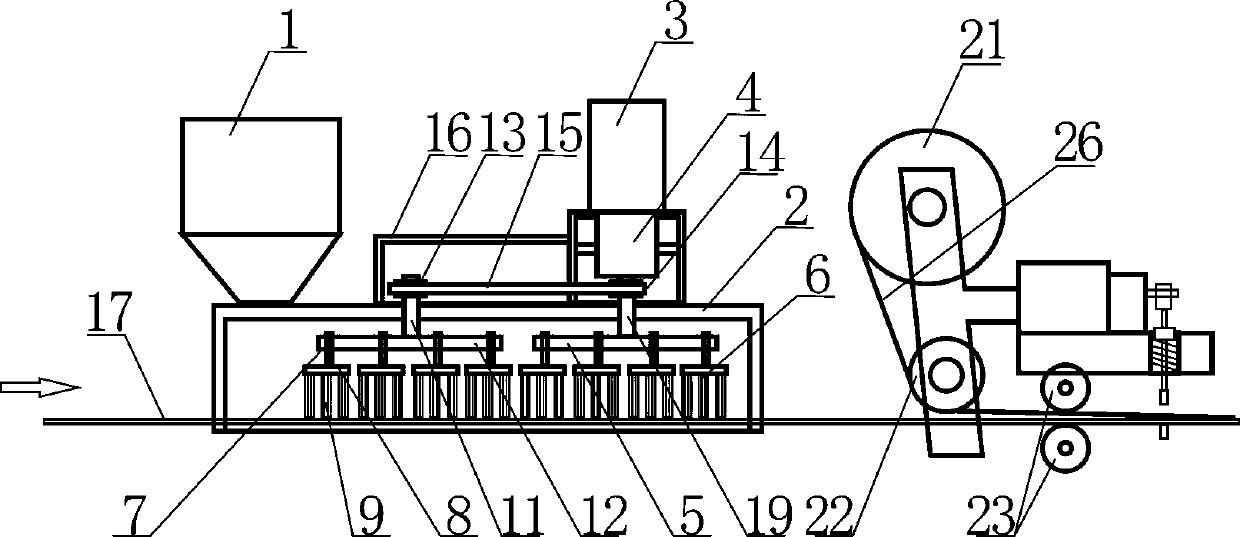

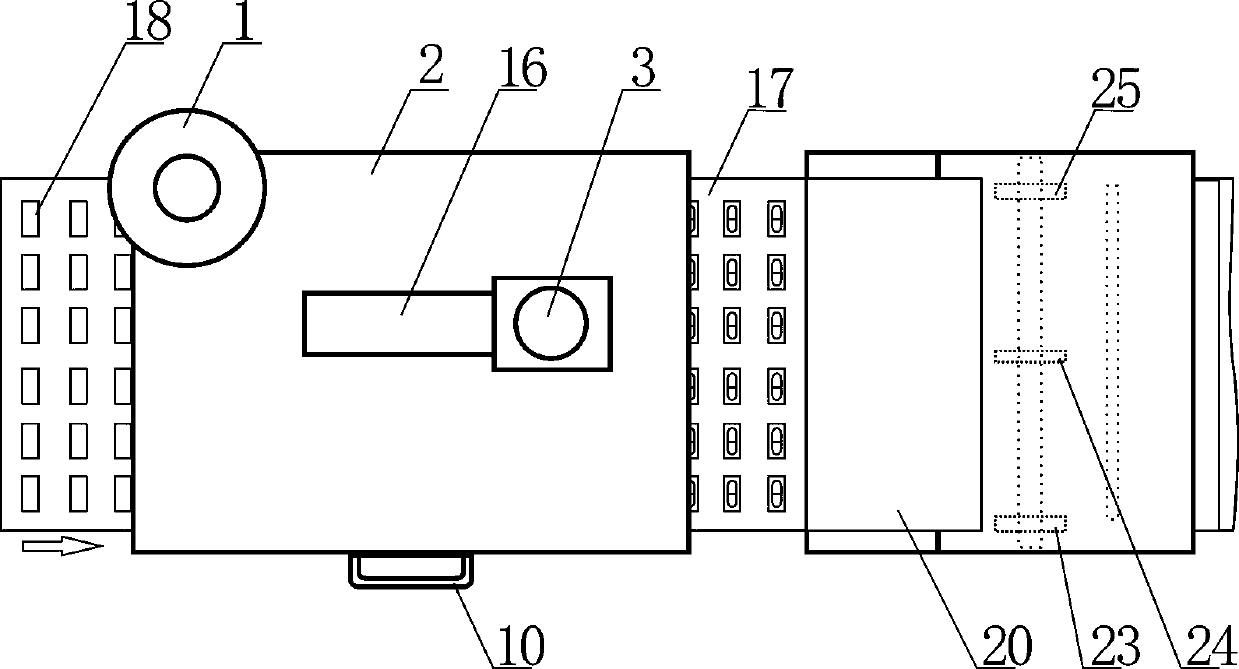

[0016] like figure 1 , 2 As shown, the tablet cloth sealing blister packaging machine includes a cloth device and a sealing device 20. The sealing device 20 includes a feeding tray 21, a guide roller 22 and a set of heating and welding pressing wheels. The sealing film 26 on the feeding tray 21 is guided The roller 22 is laid flat on the surface of the blister packaging tape 17, and the heating and welding pressing wheel set includes a heating front pressing wheel set 23, a heating middle pressing wheel set 24 and a heating rear pressing wheel set 25. The heating front pressing wheel set 23, heating The middle pressure wheel group 24 and the heating rear pressure wheel group 25 are composed of two heating wheels corresponding to the upper and lower sides. The blister packaging tape 17 and the sealing film 26 pass through the two heating wheels. The heating front pressure wheel The group 23 and the heated rear pressure wheel group 25 are used to weld both sides of the sealing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com