Intermediate film for laminated glass and laminated glass containing intermediate film

A technology of laminated glass and interlayer film, applied in the direction of glass/slag layered products, layered products, chemical instruments and methods, etc., can solve the problems of low relative strength and low strength, and achieve less stress deformation and high glass strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Prepare raw materials by the following parts by weight:

[0032] 0.3 part of antioxidant;

[0033] 15 parts of sodium acrylate;

[0034] 0.10 part of ultraviolet absorber;

[0035] 4 parts polyethylene;

[0036] 85 parts of ethylene;

[0037] The preparation method is as follows: the raw materials are added into the mixer according to the weight and mixed evenly, and then kneaded in the extruder, the temperature of the extruder is controlled at 130-140°C, and the obtained extrudate is cast and calendered to form a film. Shaping is carried out through cooling and pulling, and finally through the winding process to obtain the interlayer film for laminated glass.

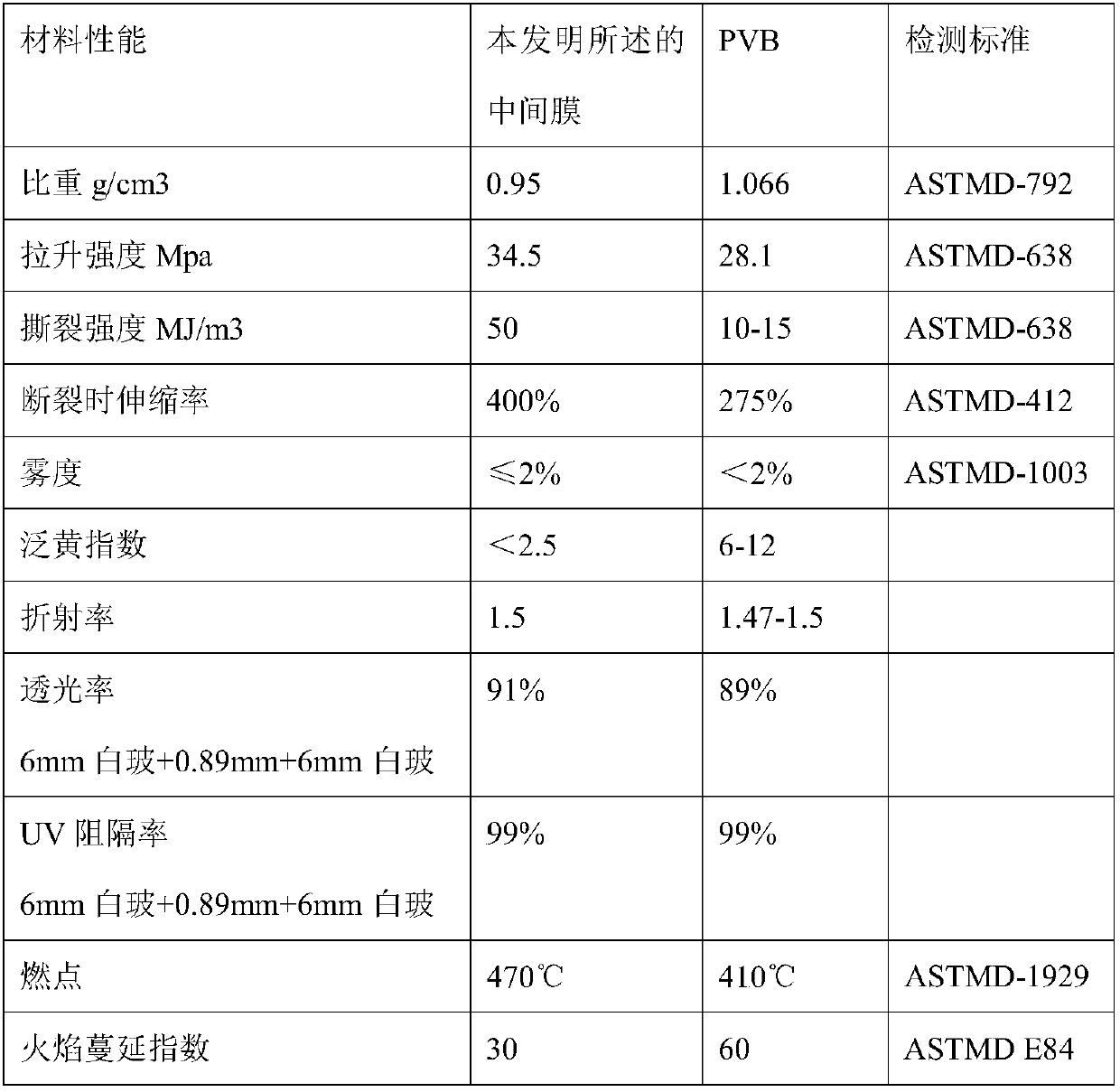

[0038] The intermediate film prepared by the embodiment is compared with the commercially available traditional intermediate film, and the results are as follows:

[0039]

Embodiment 2

[0041] Prepare raw materials by the following parts by weight:

[0042] 0.2 part of antioxidant;

[0043] 10 parts of sodium acrylate;

[0044] 3 parts polyethylene;

[0045] 80 parts of ethylene;

[0046] The preparation method is as follows: the raw materials are added into the mixer according to the weight and mixed evenly, and then mixed in the extruder, the temperature of the extruder is controlled at 120-150°C, and the obtained extrudate is cast and calendered to form a film, Shaping is carried out through cooling and pulling, and finally through the winding process to obtain the interlayer film for laminated glass.

Embodiment 3

[0048] Prepare raw materials by the following parts by weight:

[0049] 0.3 part of antioxidant;

[0050] 0.06 part of ultraviolet absorber;

[0051] 12 parts of sodium acrylate;

[0052] 4 parts polyethylene;

[0053] 82 parts of ethylene;

[0054] The preparation method is as follows: the raw materials are added into the mixer according to the weight and mixed evenly, and then mixed in the extruder, the temperature of the extruder is controlled at 120-150°C, and the obtained extrudate is cast and calendered to form a film, Shaping is carried out through cooling and pulling, and finally through the winding process to obtain the interlayer film for laminated glass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com