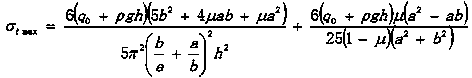

Method for determining instable critical thickness of horizontal ore pillar in multi-level simultaneous mining mode

A technology of critical thickness and determination method, which is applied in ground mining, mining equipment, underground mining, etc., can solve problems such as distortion of research results, and achieve the effects of simple determination method, reduced waste of resources, and safe recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

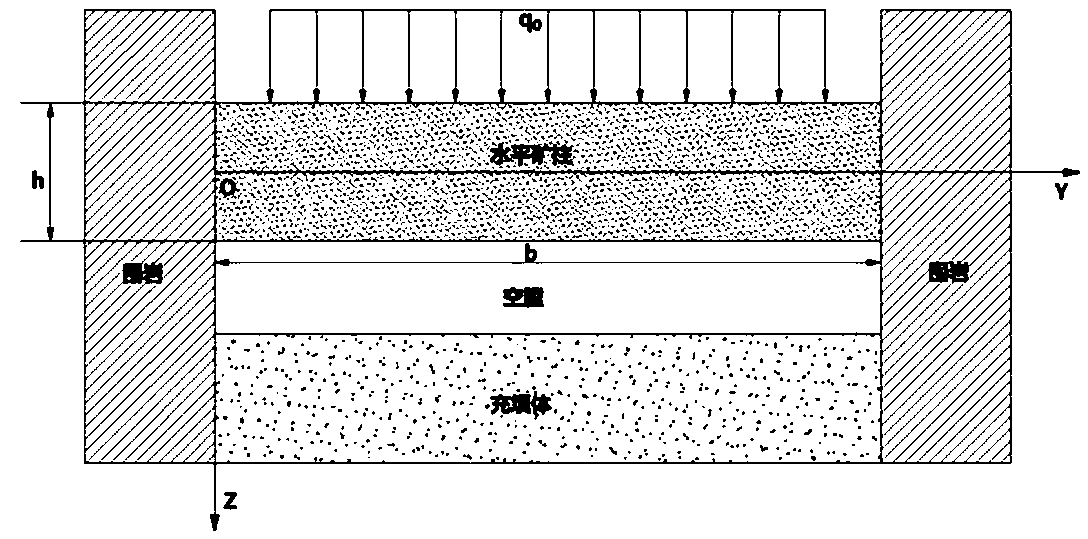

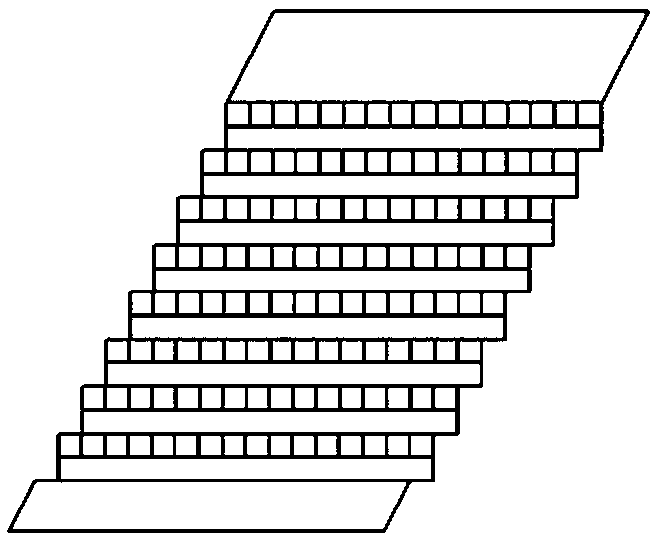

[0032] 1. Numerical simulation of downward horizontal layered rectangular approach cemented filling mining method

[0033] (1) Geometric model establishment

[0034] Modeling area selection: FLAC 3D software was used for numerical analysis and research. According to the research problem and the mining status of a lead-zinc mine, the ore body from the depth of 680m to 760m below the surface was selected as the research and analysis object, and the ore body dip angle was 72° , take 40m upward along the ore body strike, and 50m perpendicular to the ore body strike direction to establish a model. The upper part of the ore body and the surrounding rocks are taken as 3 times the size of the ore body, and the surrounding rocks at the bottom are taken as 100m. The numerical model is a cuboid (350m×280m×420m), enclosing the ore body in the middle.

[0035] Model boundary and failure criterion: Displacement constraints (Fix) are used around the model and at the bottom, free bounda...

Embodiment 1

[0055] A lead-zinc mine adopts the panel mechanized downward layered approach type cemented paste filling mining method, and the upper and lower layers are vertically staggered. With the simultaneous mining of multiple middle sections, the unmined ore body in the middle section of 760 underwent large deformation under the condition of weak bottom support and high stress, and the ore showed fragmentation; the ore pillar had obvious tension cracks and new cracks , the closed joints expand, and there are obvious dislocations; at the same time, the filling body does not connect to the bottom. Based on the above phenomena, it can be seen that the horizontal ore pillar in the middle section of 760 was formed and gradually destroyed. At this time, the vertical thickness of the horizontal ore pillar is 22m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com