Method for correcting oil saturation based on liquid drainage phenomenon through oil-liquid ratio of rock core sidewall

A technology of saturation and core, which is applied in the field of correcting oil saturation by using the oil-liquid ratio of the core side wall during the coring period based on the liquid drainage phenomenon, which can solve problems such as swelling, oil and water liquid loss, and difficult correction of pore changes, and achieve Clear technical thinking, good operability, simple application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the above and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments are listed below and shown in the accompanying drawings in detail as follows.

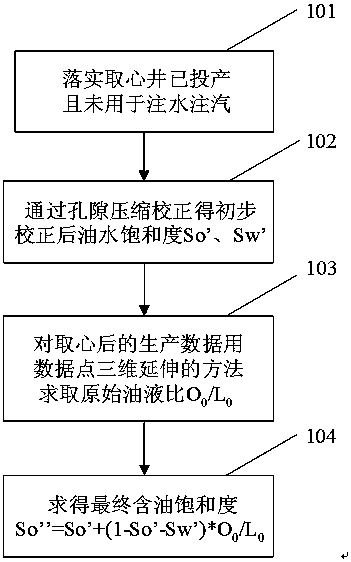

[0021] Such as figure 1 as shown, figure 1 It is a flow chart of the method for correcting oil saturation by core sidewall oil-liquid ratio based on liquid drainage phenomenon of the present invention.

[0022] Step 101, according to the production data of the oil area, confirm that the coring wells that need data processing or the adjacent wells have been put into production, and have oil production and liquid production data; it is also necessary to confirm that the core sealing rate is up to standard, and the coring wells have been put into production It means that oil production has started, and it has not been used for water injection or steam injection.

[0023] Step 102, for this type of coring well, the porosity overburden pressure correction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com