High frequency transformer

A technology of high-frequency transformers and transformers, applied in the field of high-frequency transformers, can solve problems such as dust and water vapor entering the transformer, affecting the normal operation and service life of the transformer, and achieve better convection effect, good heat dissipation effect, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

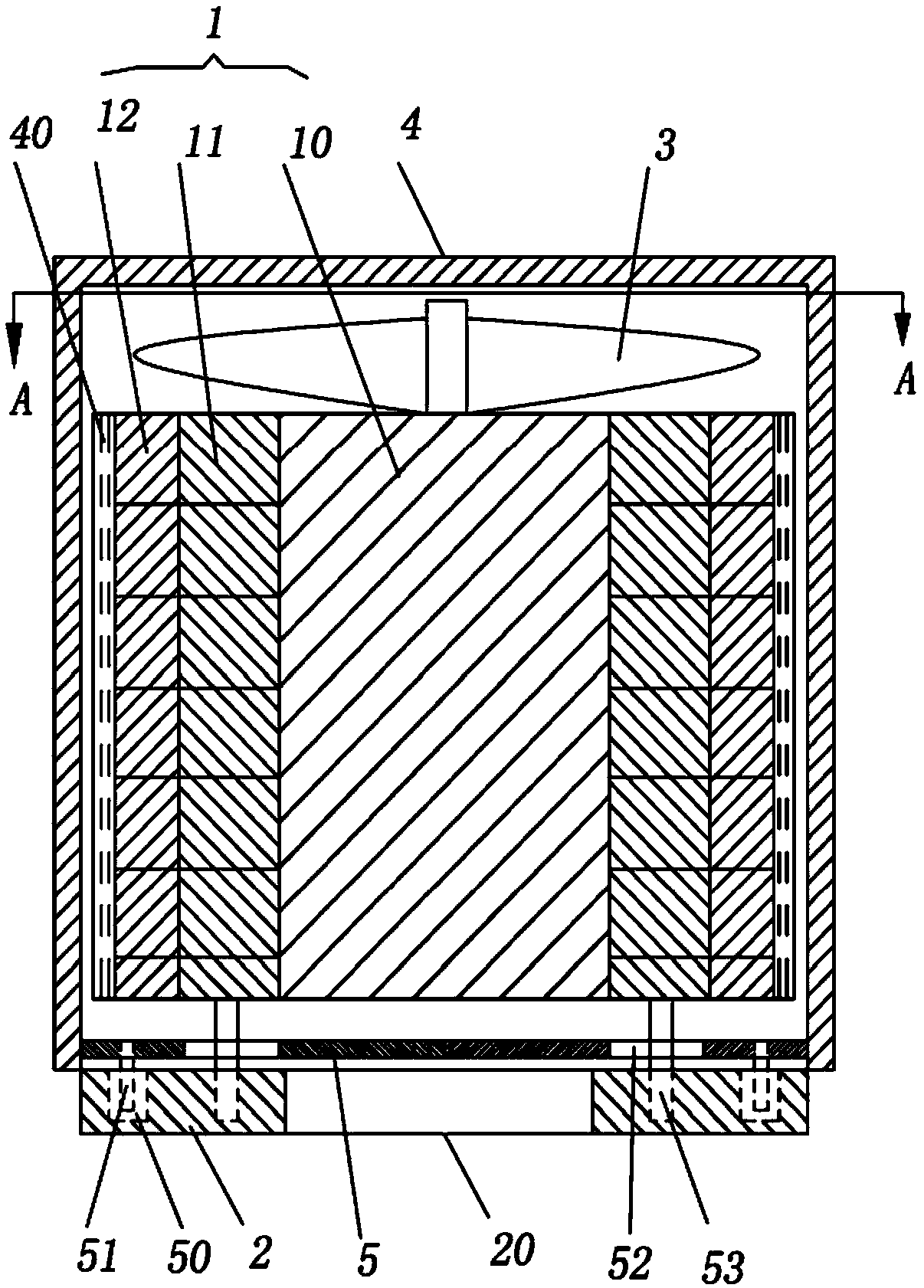

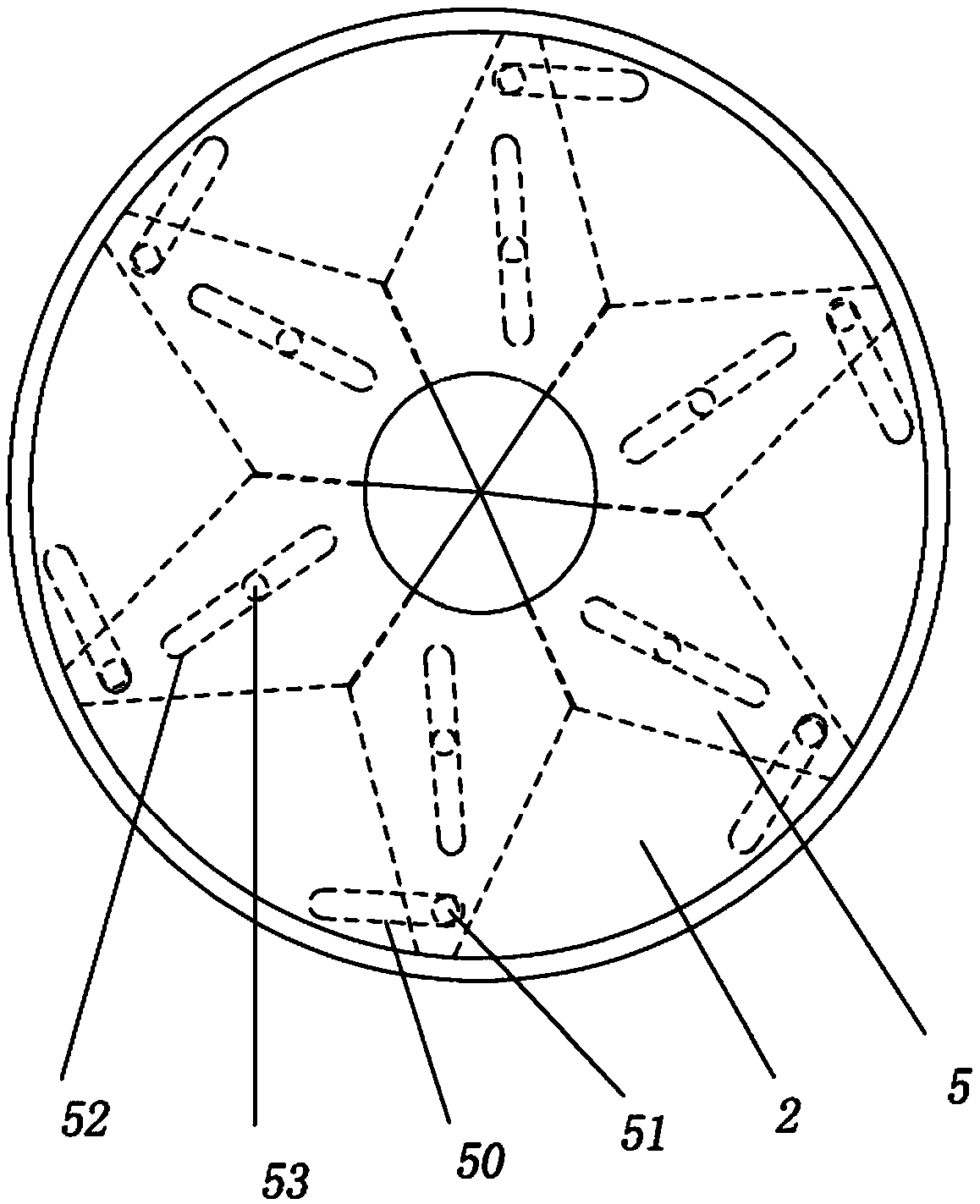

[0026] The embodiment is basically as attached figure 1 Shown: a high-frequency transformer, including a transformer main body 1, a bottom plate 2 and a cooling fan 3, and also includes a sealing cover 4, the longitudinal section of the sealing cover 4 is inverted U-shaped; the transformer main body 1 includes a cylindrical iron core 10 and is wound on Coils on the iron core 10; each set of coils includes an inner primary coil 11 and an outer secondary coil 12; the transformer main body 1 is located in the sealed cover 4, the cooling fan 3 is located on the top of the transformer main body 1, and the bottom plate 2 is located on the transformer main body 1, the sealing cover 4 and the bottom plate 2 are rotationally connected, and the sealing cover 4 and the bottom plate 2 are hermetically connected. Such as Figure 4 As shown, a hollow ventilation pipe 40 is provided around the transformer main body 1 , one end of the ventilation pipe 40 is located at the top of the transfor...

Embodiment 2

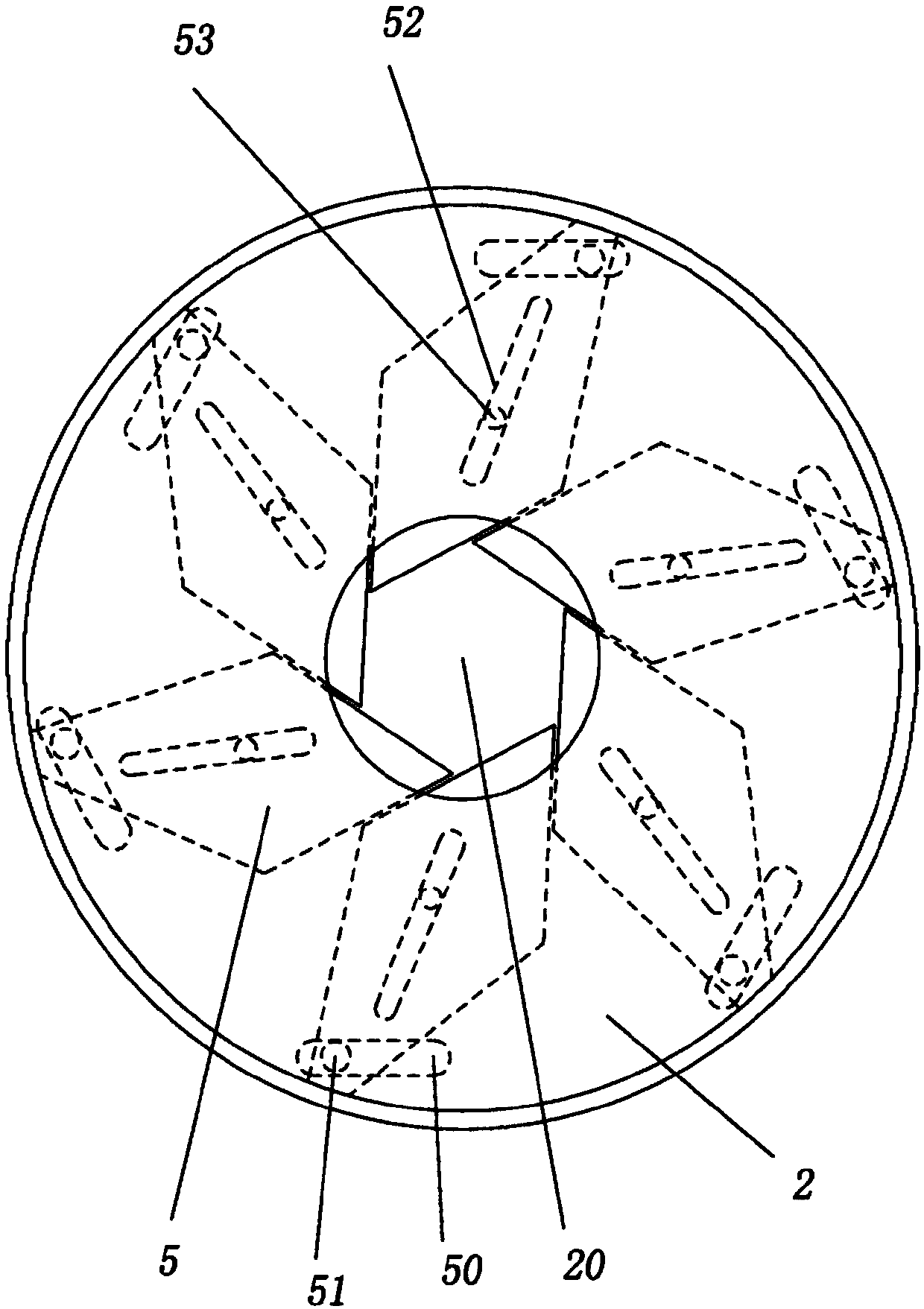

[0030] as attached Figure 5 And attached Figure 6 As shown, the difference between this embodiment and Embodiment 1 is that the number of opening and closing plates 5 is 9, and the number of corresponding pin shafts 51 , chute 50 , fixed shaft 53 and fixing groove 52 is also 9.

[0031] This embodiment has a better closing effect on the heat dissipation hole 20 , and has a better effect of preventing external dust, water vapor, etc. from entering the transformer main body 1 through the heat dissipation hole 20 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com