Device and method for generating controllable vortex electron beam

An electron beam and vortex technology, applied in the direction of circuits, discharge tubes, electrical components, etc., can solve the problems of low topological charge, unstable phase plate material, and limited service life of the phase plate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

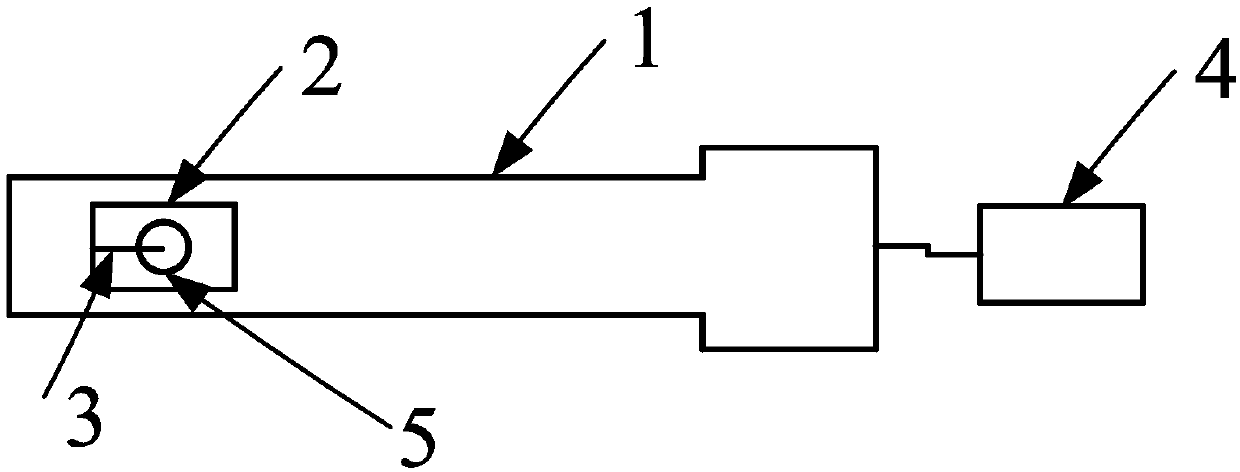

[0052] see figure 1 , the present embodiment provides a device for generating controllable vortex electron beams in TEM, the device includes: an electrical sample rod 1 , a sample chip 2 , a magnetic needle 3 wound with a conductive coil, and a magnetic field controller 4 . The end of the electrical sample rod 1 is provided with a mounting groove, and the electrode at the tail is connected to the magnetic field controller 4; the center of the sample chip 2 is provided with an aperture 5, and is placed in the mounting groove, and one end of the electrode in the sample chip 2 is connected to the sample The electrodes in the rod 2 are connected; the magnetic needle 3 wound with a conductive coil is placed horizontally on the surface of the sample chip 2, and the tip of the magnetic needle 3 wound with a conductive coil is aligned with the center of the aperture 5, and the conductive coil and the electrode sheet of the sample chip 2 are separately connected at one end.

[0053] I...

Embodiment 2

[0059] This embodiment provides a method for preparing a magnetic needle 3, specifically:

[0060] First, a magnetic wire with a diameter of 10 um and a length of 100 um is selected, and the magnetic wire is Ni.

[0061] Then, an insulating layer is deposited on the surface of the magnetic wire.

[0062] In this embodiment, the specific process of depositing an insulating layer on the surface of the magnetic wire is as follows:

[0063] (1) Measure an appropriate amount of organic solvent (the organic solvent can be cyclohexane, isopropanol) in a three-necked flask, and drop an appropriate amount of deionized water with a pipette gun, stir for about 10 minutes, and then add an appropriate amount of ammonia water , sonicate at room temperature for about 10 minutes, and let it stand; (2) mix the above-mentioned organic solvent with TEOS, and then sonicate at room temperature for about 5 minutes to form an insulating liquid; (3) put the fixed magnetic wire in a beaker, and put ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com