Method for producing bearing components by means of a production line, production line and production system

A technology for bearing components and production equipment, which is applied in the direction of bearing components, mechanical equipment, manufacturing tools, etc., can solve the problems such as the influence of the range of tolerance on the dimensional stability of surface quality bearing components, and achieve improved dimensional stability, reduced contact, and high running speed The effect of stationarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

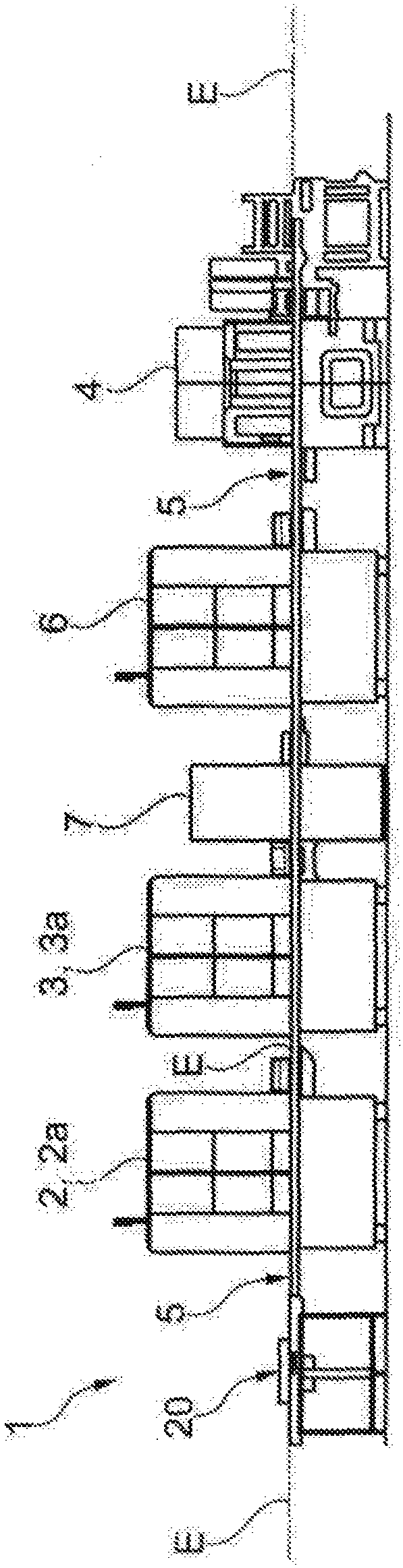

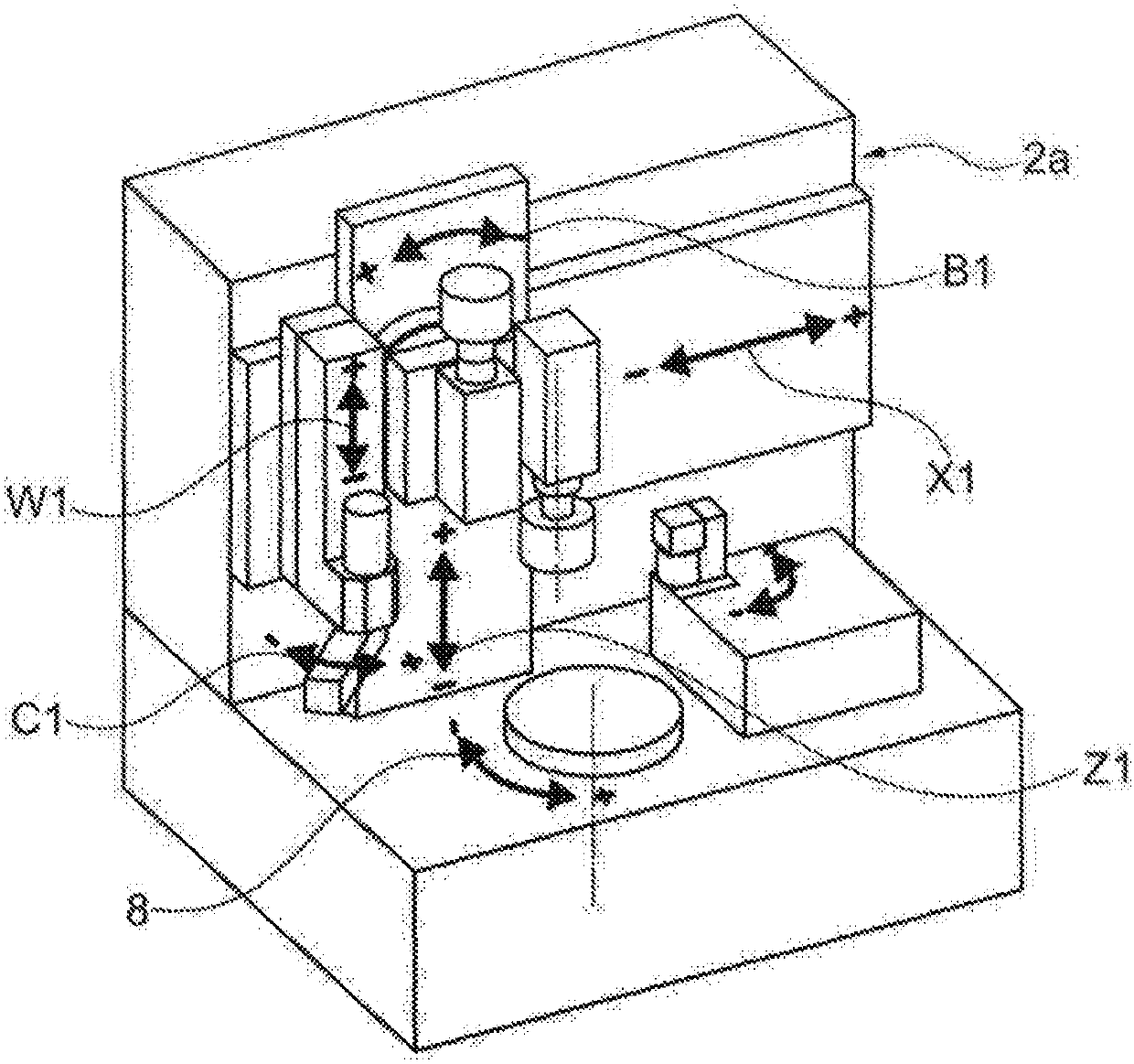

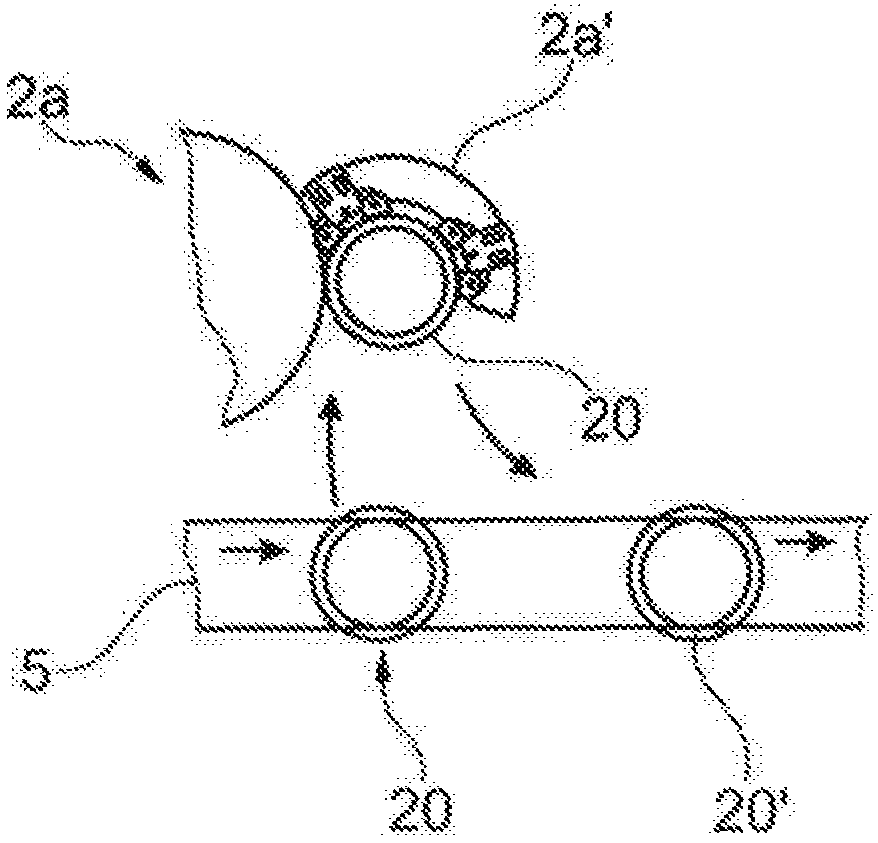

[0033] figure 1 A production line 1 for producing bearing components, in particular bearing rings 20 , is shown in front view, comprising a grinding machine 2 , a honing machine 3 , a cleaning unit 4 and a transport unit 5 . Furthermore, a measuring unit 7 and a demagnetization unit 6 are located between the honing machine 3 and the cleaning unit 4 . The bearing components are transported through the production line 1 by means of the transport unit 5 and are conveyed there successively to the grinding machine 2 , the honing machine 3 , the measuring unit 7 , the demagnetizing unit 6 and the cleaning unit 4 . The grinding machine 2 is designed here as a vertical grinding machine 2 a. The honing machine 3 is designed here as a vertical honing machine 3 a. The production line 1 is also constructed in such a way that the bearing components run through the production line in such a way that they lie on a continuous horizontal plane E. The transport units 5 are designed as conve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap