Hysteretic control for transformer based power converters

A technology of power converters and transformers, applied in high-efficiency power electronic conversion, output power conversion devices, control/regulation systems, etc., can solve problems such as converter efficiency reduction, reduce board area, reduce costs, and reduce operation The effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

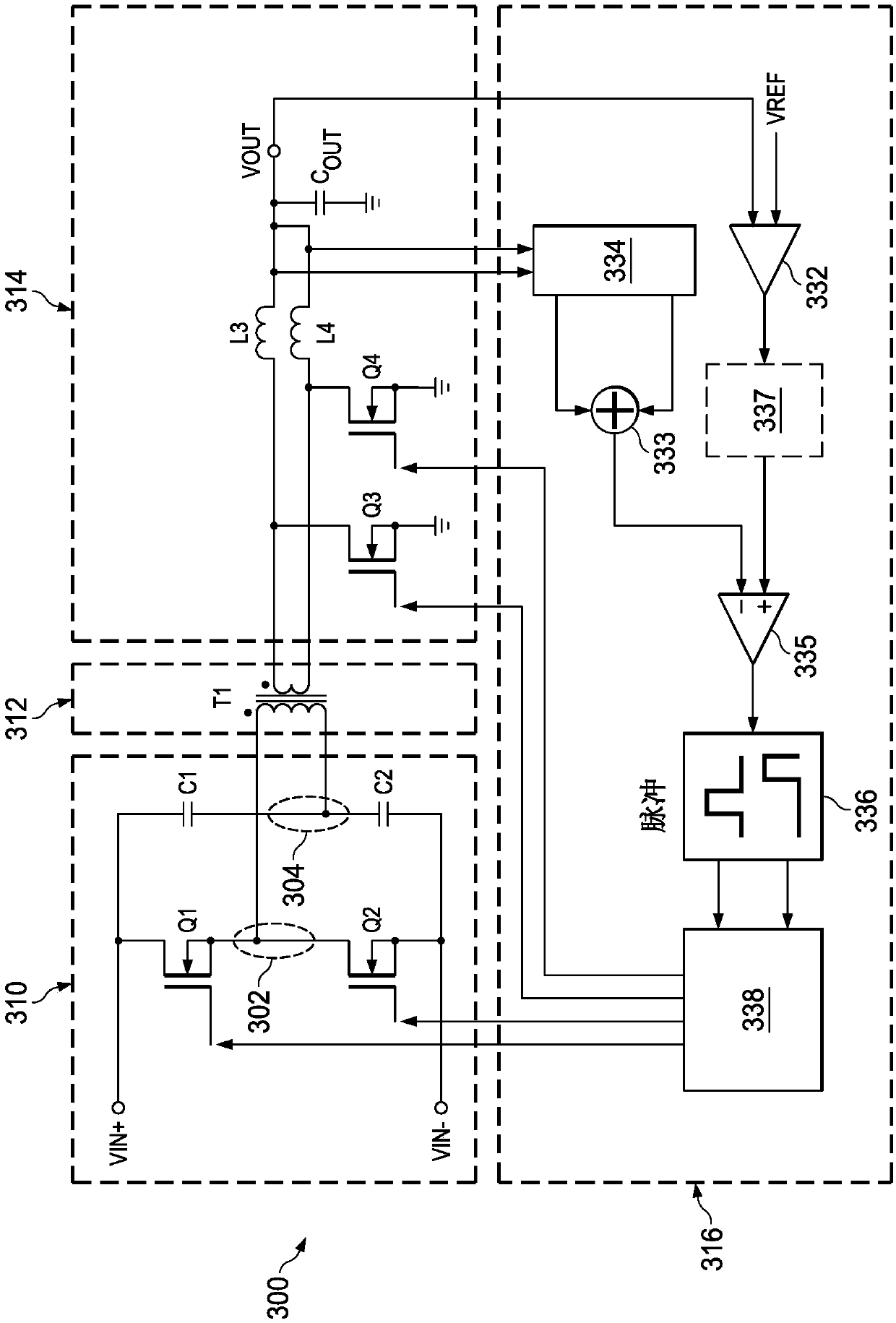

[0039] Corresponding numerals and symbols in different drawings generally refer to corresponding parts, unless otherwise specified. The figures are not necessarily drawn to scale.

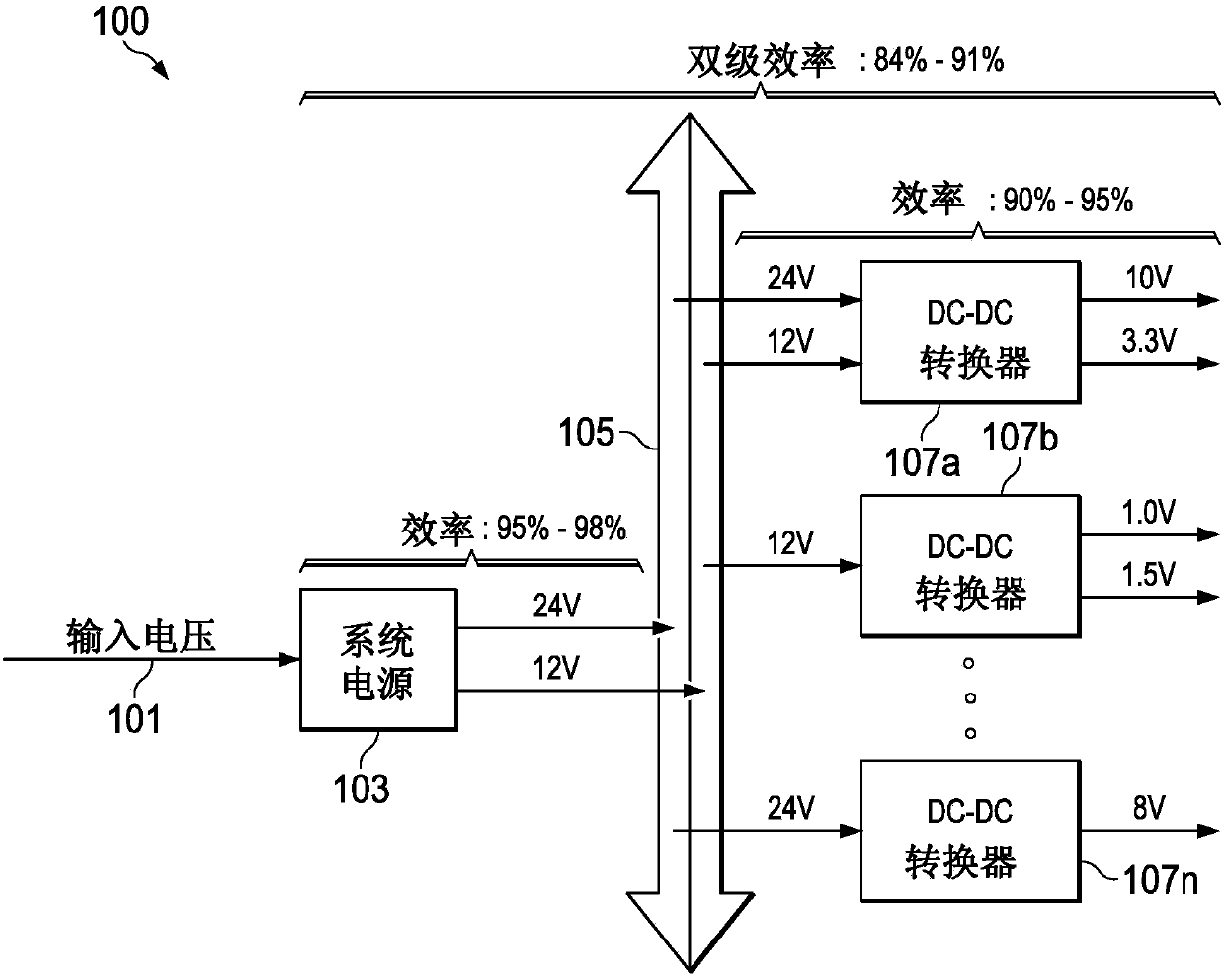

[0040] Improvements in the size and efficiency of power converters have helped reduce the size and increase efficiency of electronic products without adversely increasing device operating temperatures.

[0041] The term "coupled" may include connections with intermediate elements, and additional elements and various connections may be used between any elements described as "coupled".

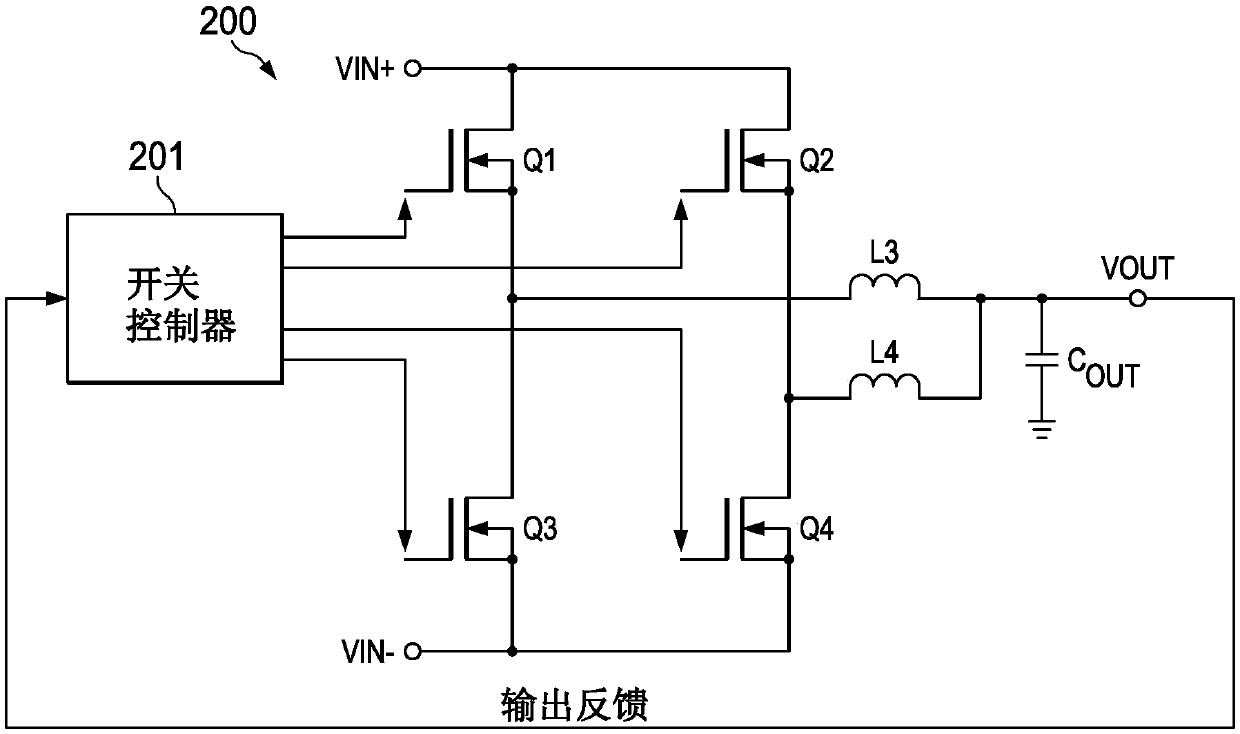

[0042] An aspect of the example embodiments provides hysteretic control of a transformer-based power converter configured to be similar in certain characteristics to a buck or step-down converter topology, however, these configurations further A transformer is used to step down the high input voltage to a low voltage while also increasing the current according to the turns ratio of the transformer. Using a transfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com