Washing, cooking and shelling integrated processing device for mussels

A processing equipment and mussel technology, applied in the field of aquatic product processing devices, can solve the problems of mussel meat damage, affecting the taste and appearance of mussel meat, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

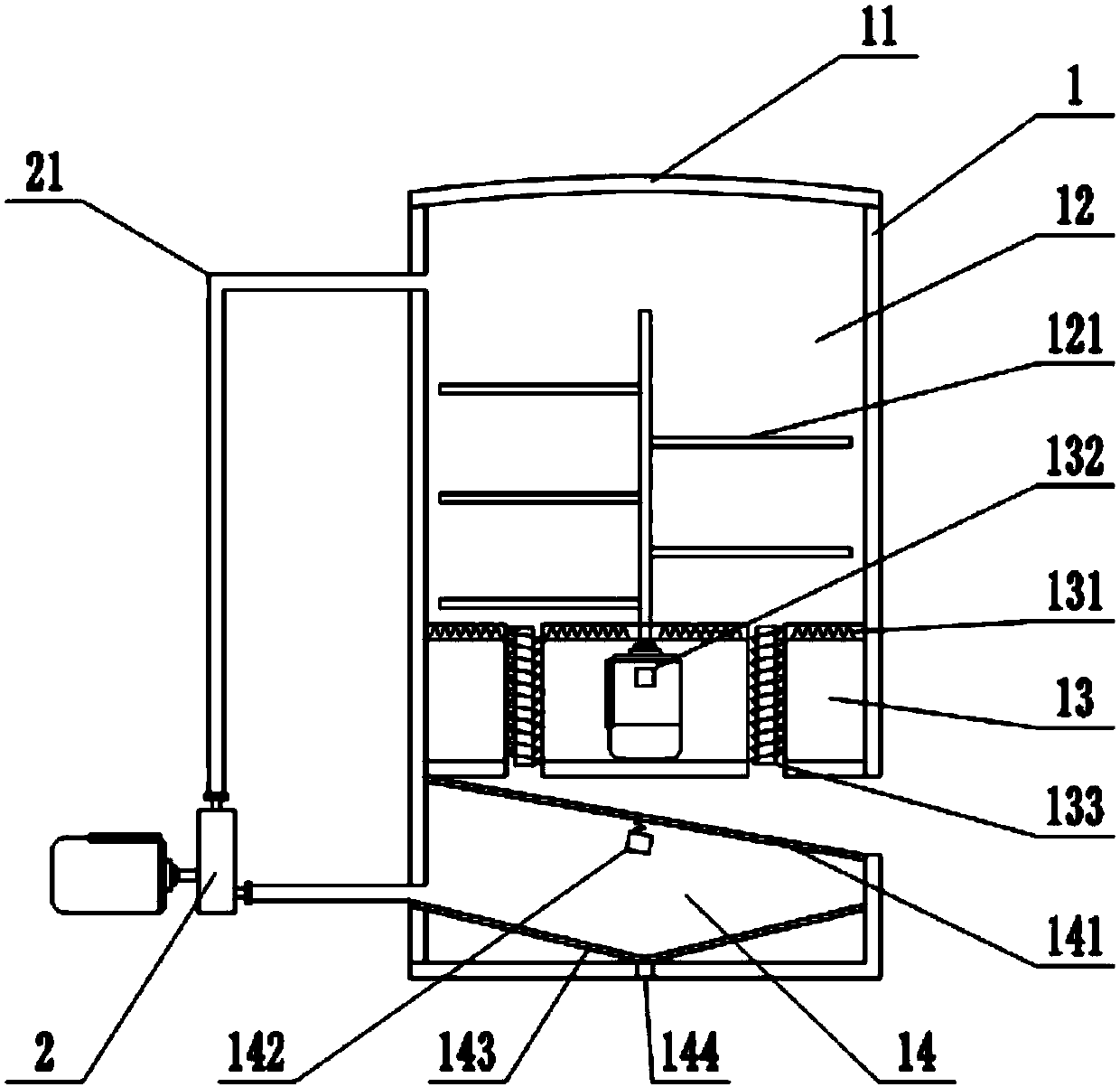

[0016] The reference signs in the drawings of the description include: box body 1, cover plate 11, heating and stirring layer 12, stirring mechanism 121, interlayer 13, heating wire 131, motor 132, screw discharge rod 133, discharge layer 14, inclined Discharge plate 141, vibrator 142, water storage tank 143, valve 144, water pump 2, conduit 21.

[0017] The embodiment is basically as attached figure 1 Shown: a mussel processing equipment integrating cleaning, cooking and shelling, including a box body 1 and a water circulation system, the box body 1 is provided with a heating and stirring layer 12, an interlayer 13 and an outlet Material layer 14, the upper end of box body 1 is connected with cover plate 11, is provided with heating wire 131 between described heating and stirring layer 12 and interlayer 13, and described interlayer 13 is provided with a motor 132, and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com