Environmentally-friendly multifunctional electric sawing machine

A multi-functional, electric saw machine technology, applied in the direction of sawing machine, metal sawing equipment, sawing machine accessories, etc., can solve the problems of unfavorable environmental protection, large material waste, slow material feeding speed, etc., to achieve convenient and automatic feeding , Ensure the working environment, reduce the effect of work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

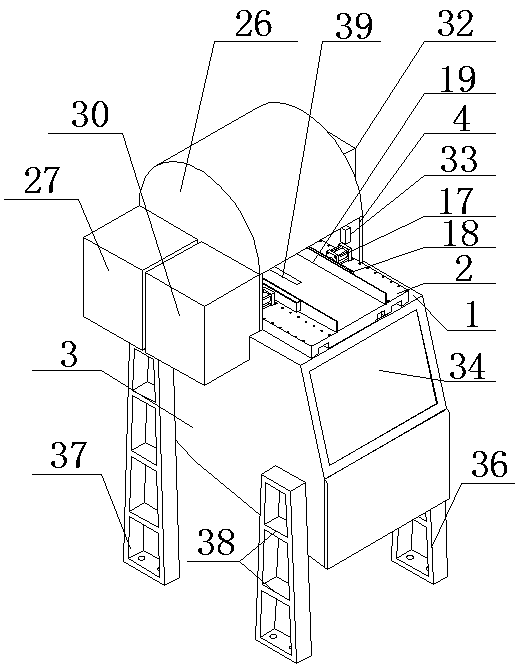

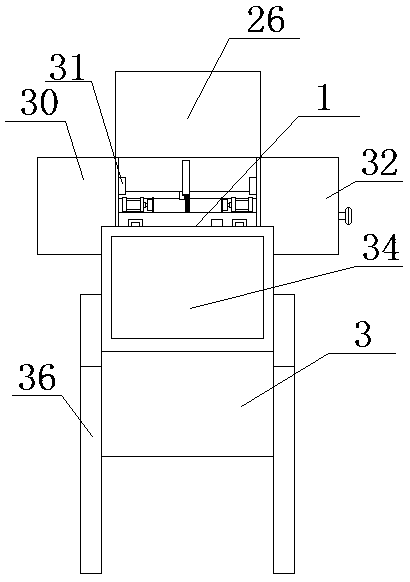

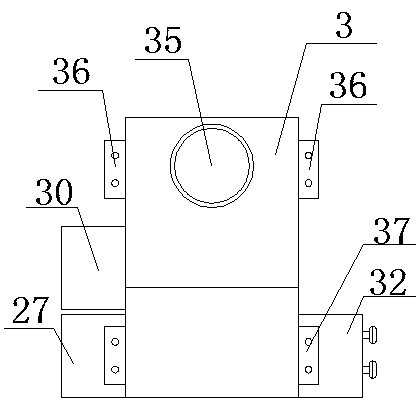

[0033] An environment-friendly multifunctional electric saw machine of the present invention comprises a frame 1, a workbench 2 and a cutting mechanism, the frame 1 is provided with a workbench 2, the upper part of the workbench 2 is provided with a cutting mechanism; There is a material storage box 3, the inclination angle of the bottom surface of the material storage box 3 is 30°, the front end of the bottom of the material storage box 3 is provided with a discharge port 35, the frame 1 and the material storage box 3 are integrally formed, and the front end of the frame 1 is provided with an observation Window 34, symmetry welding is provided with support front leg 36 and support rear leg 37 on material storage box 3 casing outer walls, is also provided with 2 beams 38 on support front leg 36 and support rear leg 37; The top of frame 1 and workbench 2 is provided with a material transmission mechanism, the material transmission mechanism includes a transmission mechanism brac...

Embodiment 2

[0035] An environment-friendly multifunctional electric saw machine of the present invention comprises a frame 1, a workbench 2 and a cutting mechanism, the frame 1 is provided with a workbench 2, the upper part of the workbench 2 is provided with a cutting mechanism; There is a material storage box 3, the inclination angle of the bottom surface of the material storage box 3 is 60°, the front end of the bottom of the material storage box 3 is provided with a discharge port 35, the frame 1 and the material storage box 3 are integrally formed, and the front end of the frame 1 is provided with an observation Window 34, material storage box 3 casing outer walls are symmetrically welded with support front leg 36 and support rear leg 37, and support front leg 36 and support rear leg 37 are also provided with 3 beams 38; The top of frame 1 and workbench 2 is provided with a material transmission mechanism, the material transmission mechanism includes a transmission mechanism bracket 5...

Embodiment 3

[0037]An environment-friendly multifunctional electric saw machine of the present invention comprises a frame 1, a workbench 2 and a cutting mechanism, the frame 1 is provided with a workbench 2, the upper part of the workbench 2 is provided with a cutting mechanism; There is a material storage box 3, the inclination angle of the bottom surface of the material storage box 3 is 50°, the front end of the bottom of the material storage box 3 is provided with a discharge port 35, the frame 1 and the material storage box 3 are integrally formed, and the front end of the frame 1 is provided with an observation Window 34, symmetry welding is provided with support front leg 36 and support rear leg 37 on material storage box 3 casing outer walls, is also provided with 2 beams 38 on support front leg 36 and support rear leg 37; The top of frame 1 and workbench 2 is provided with a material transmission mechanism, the material transmission mechanism includes a transmission mechanism brack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com