Device and method for pattern processing on surface of ceramic ball by using femtosecond laser

A femtosecond laser and ceramic ball technology, which is applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problem of incomplete processing of ceramic materials, and achieve fast three-dimensional parameterized pattern femtosecond laser processing and stable strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

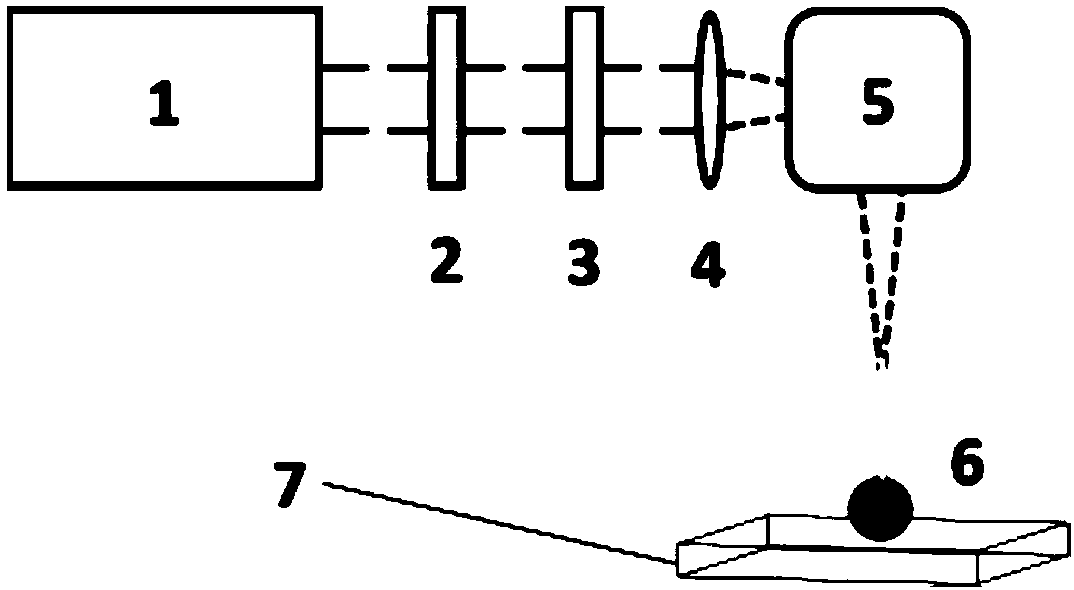

[0028] Such as figure 1 As shown, the present invention provides the device that utilizes femtosecond laser to carry out pattern processing on ceramic ball surface, comprises programming software, femtosecond laser amplifier 1, half-wave plate 2, polarizer 3, converging lens 4, scanning vibrating mirror 5, not Ceramic ball 6 with regular shape and stage 7 equipped with a three-dimensional precision displacement platform; half-wave plate 2, polarizer 3, converging lens 4 and scanning galvanometer 5 are placed in sequence at the output end of femtosecond laser amplifier 1, irregular The topographical ceramic ball 6 is placed on the stage 7 of the three-dimensional precision displacement platform, and the deflection of the scanning galvanometer 5 is controlled by programming software; the femtosecond laser of the femtosecond laser amplifier 1 passes through the half-wave plate 2 and the polarizer 3 in sequence 1. After the converging lens 4, the optical filament can be formed nea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center wavelength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com