Glass plate drilling equipment

A technology for drilling equipment and glass plates, which is applied to stone processing equipment, stone processing tools, work accessories, etc., and can solve the problems of heavy labor, laborious work, and low productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the examples.

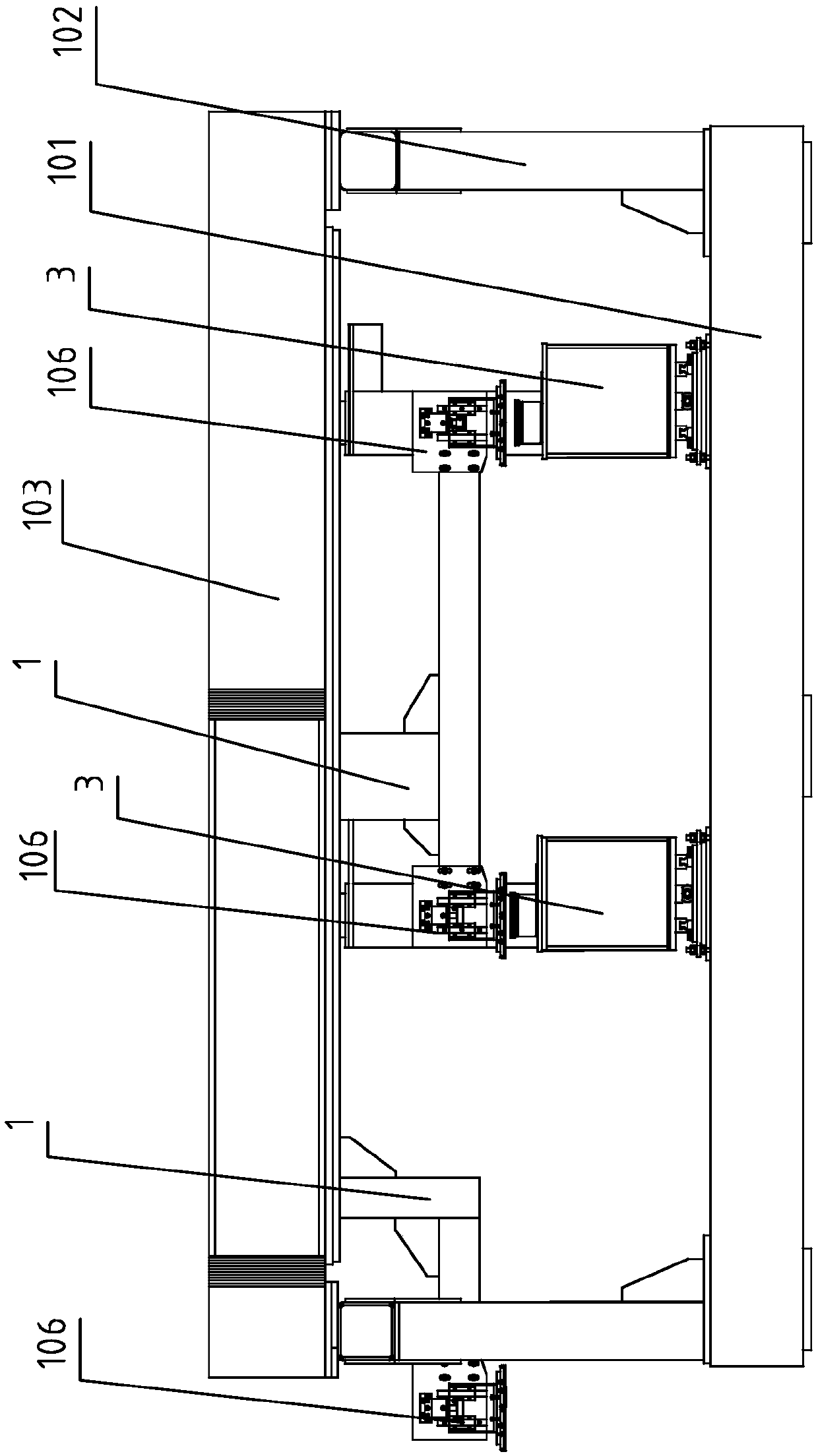

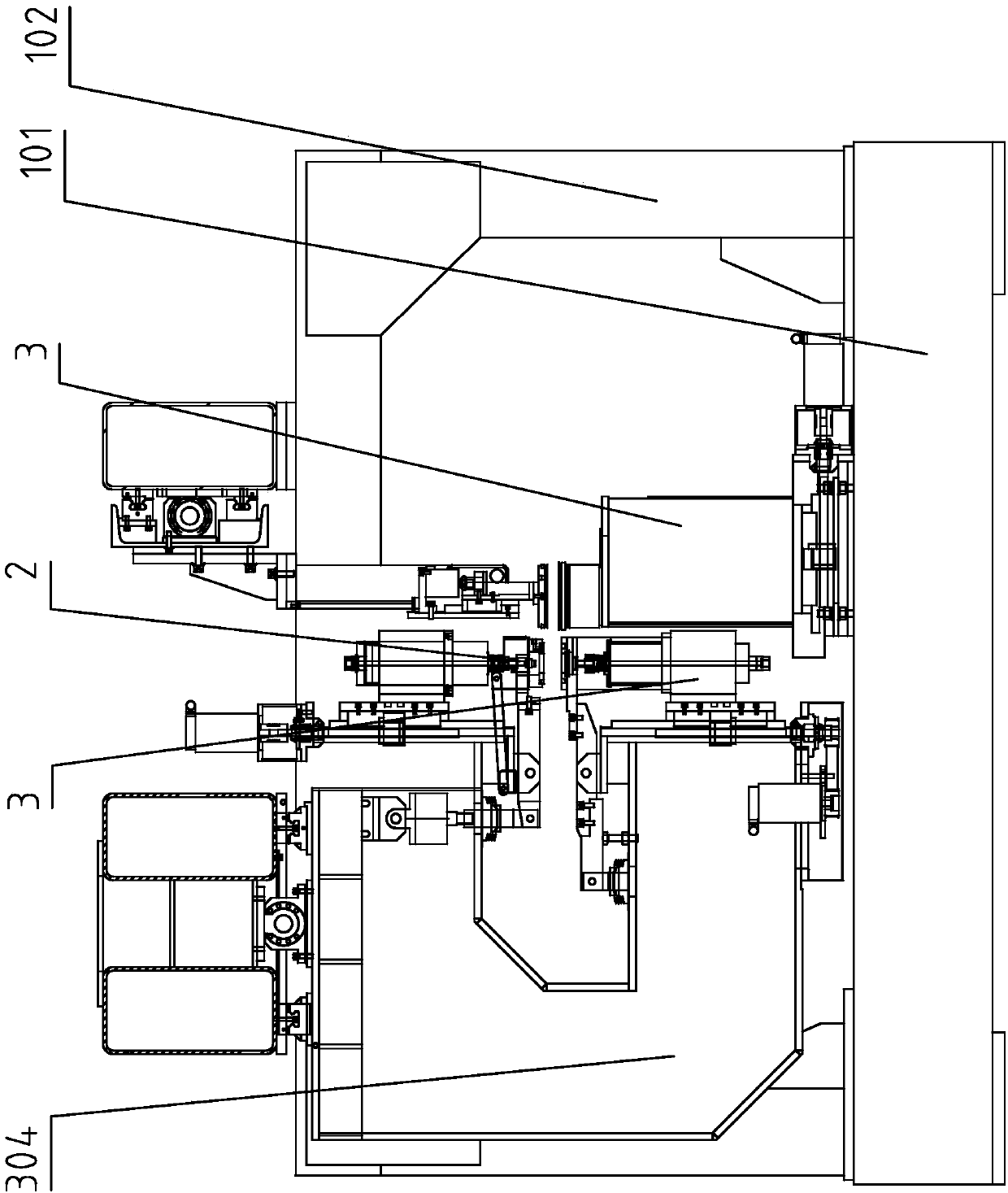

[0034] The first part is the conveying part 1 that quickly transports the glass plate to the designated station, the second part is the clamping part 2 that clamps the glass plate and stabilizes it, and the third part is through the rotating platform, X-axis movement and Y-axis movement A positioning component 3 for accurately positioning the drilling position of the glass plate.

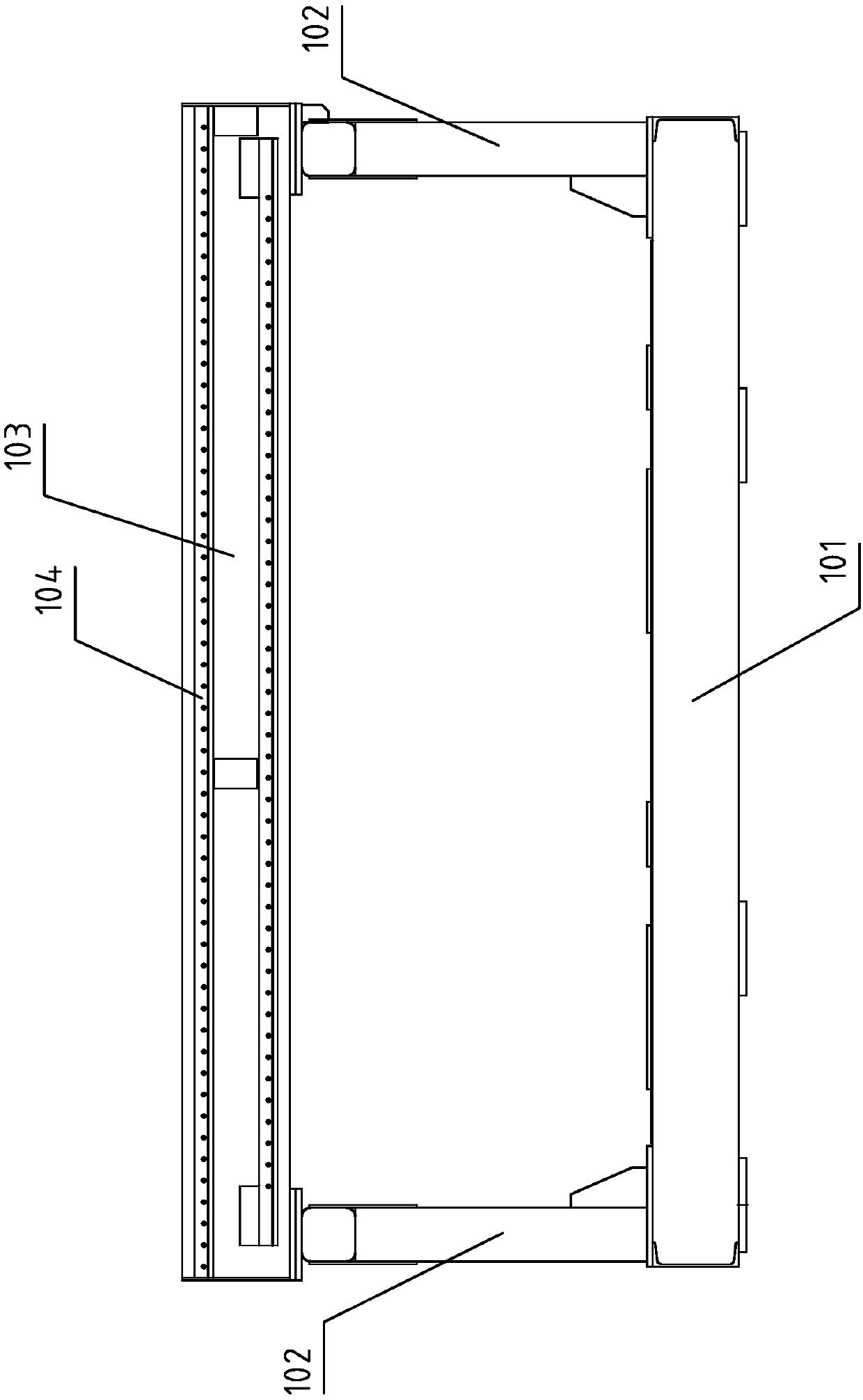

[0035] The conveying part 1 is provided with a body base 101, and the left and right sides of the body base 101 are provided with a column assembly 102, and a Y-axis conveying beam 103 is erected on the column assembly 102, and two sets of upper and lower Y-axis rails 104 are arranged on the Y-axis conveying beam 103. The axis rail 104 is provided with a slider assembly 105 that can slide along the Y axis rail 104. The slider assembly is provided with a slider 1051. The slider 1051 is provided with a sli...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap