Heavy-duty truck balance shaft support

A technology for heavy-duty trucks and balance shaft brackets, which is applied to suspensions, vehicle components, interconnection systems, etc., can solve the problems of deformation and tearing of balance shaft brackets, uneven stress on brackets, and reduction of vehicle load capacity, etc. The effect of vehicle safety, force equalization, and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

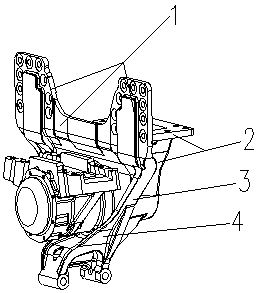

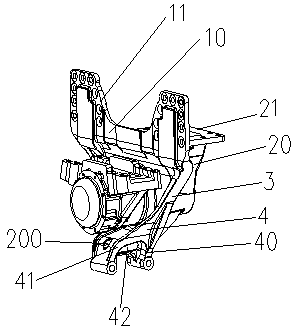

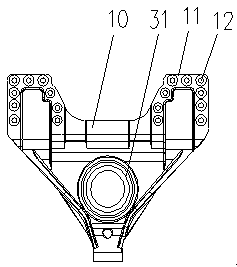

[0031] see Figure 1 to Figure 8 , the present invention is: a heavy-duty truck balance shaft bracket, which includes a frame connection part, a load-bearing support structure arranged on one side of the frame connection part, and an axle housing arranged at the connection between the frame connection part and the load-bearing support structure The installation assembly, and the thrust rod installation support structure arranged at the bottom of the axle housing installation assembly.

[0032] The connecting part of the frame is in a concave shape, which includes a connecting plate, fixed fins arranged at both ends of the connecting plate, several bolt fixing holes arranged on the fixed fins, and each fixed fin is provided with an L-shaped notch , several bolt fixing holes are equidistantly arranged around the L-shaped not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com