Integrated type planet gear reduction differential motor used for new-energy automobile

A technology of planetary gear reduction and new energy vehicles, which is applied to vehicle components, electric power devices, control devices, etc., can solve the problems of taking up a lot of space, cumbersome installation and operation, and reducing the speed of rotation, so as to reduce the overall weight, compact structure, and occupancy The effect of less space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

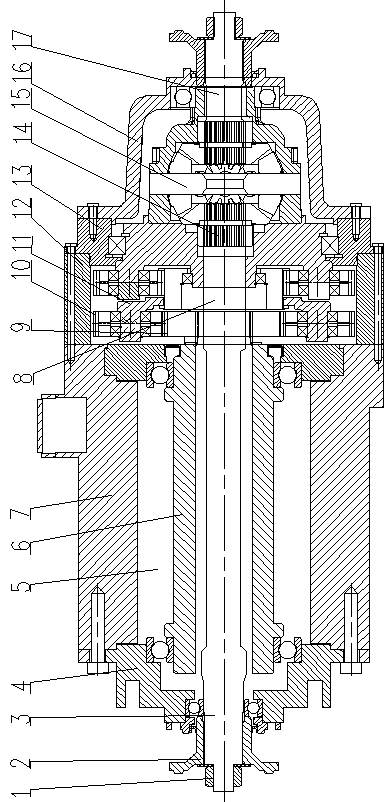

[0013] As shown in the figure, an integrated planetary gear reduction differential motor for new energy vehicles includes a drive motor 5, the output end of the drive motor 5 is connected to a differential 15 through a reducer 8, the drive motor 5, and the reducer 8. The differential gear 15 has a motor housing 7, a reducer housing 12, a differential gear housing 16 respectively, the drive motor 5, the gear reducer 8, and the differential gear 15 are coaxially arranged, and the motor housing 7, the gear reducer housing 12, the differential gear The transmission casing 16 is integrated with the vehicle casing, and the differential also has a differential inner casing, which is fixedly connected to the output end of the speed reducer 8; the speed reducer 8 is a hollow shaft planetary gear reducer, The differential 15 is a planetary gear differential; the left and right side gears 14 are installed inside the differential 15, and the inner shell of the differential cooperates with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com