Transparent temperable heat insulating glass and processing method thereof

A heat-insulating glass and transparent technology, applied in glass tempering, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of glass that is not easy to be painted, the hardness of the film layer is not enough, painting defects, etc., and achieve accelerated aging and fading. , The effect of lasting hydrophilic function and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

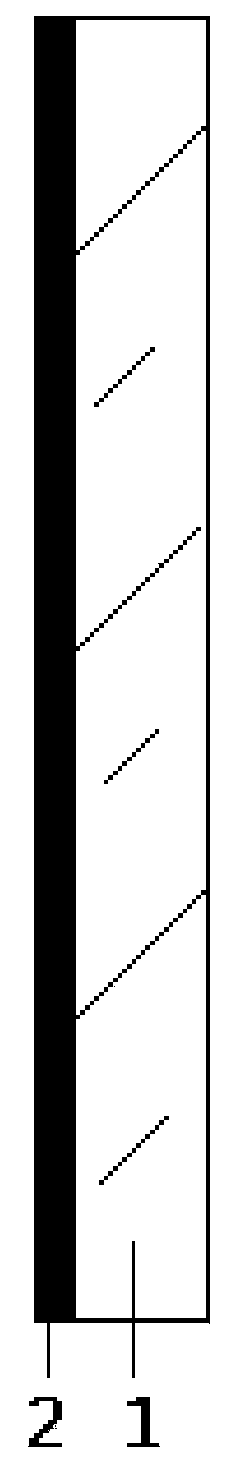

Image

Examples

Embodiment 1

[0089] Embodiment 1 glass temperable thermal insulation coating

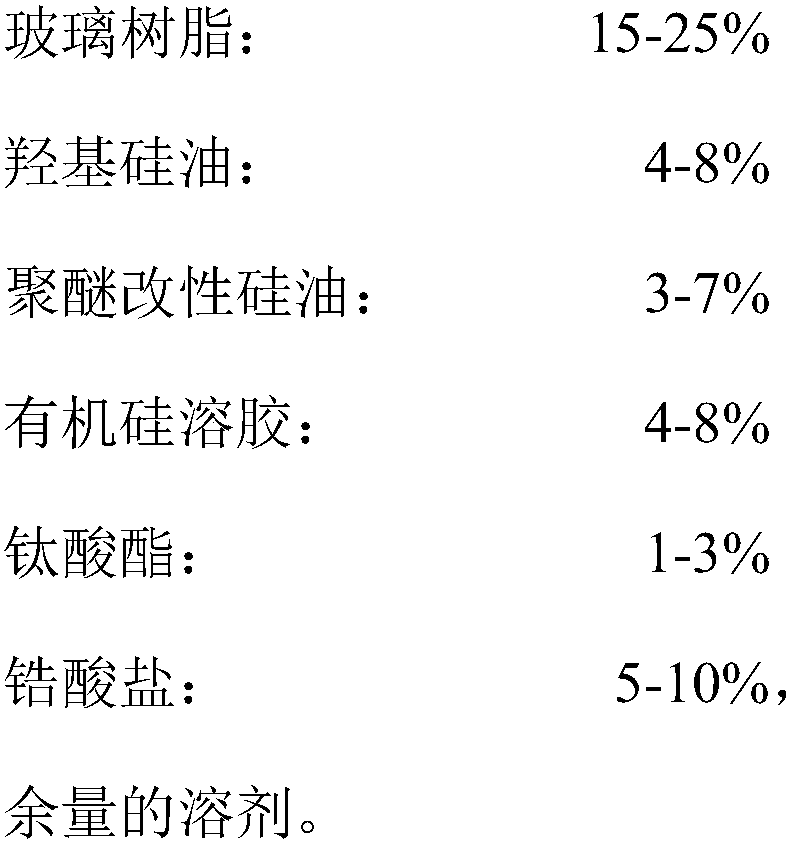

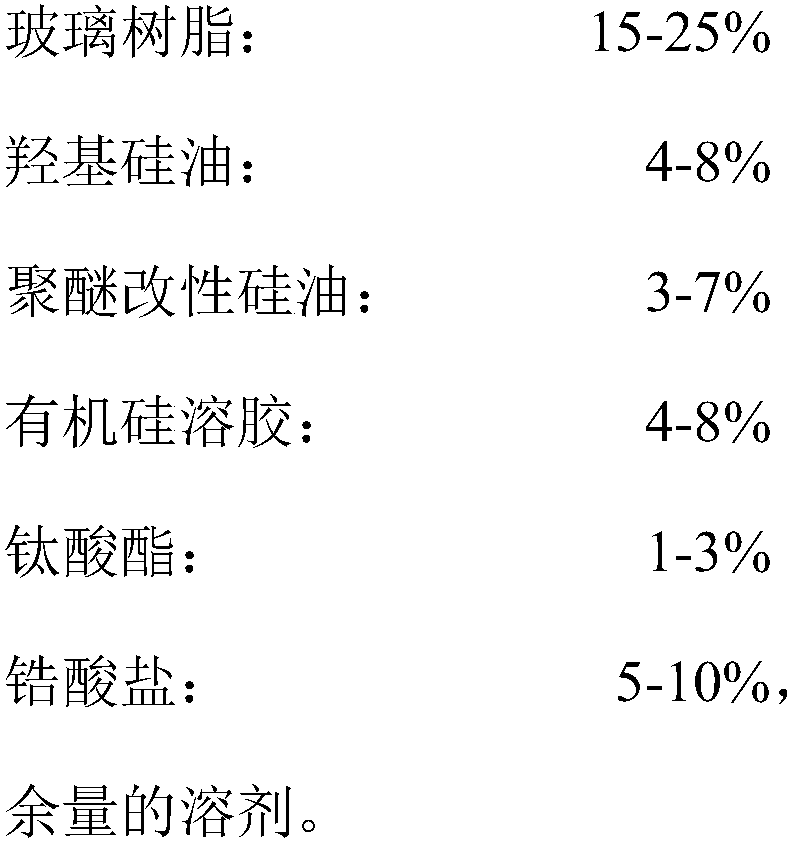

[0090] by weight,

[0091] 1 part temperable coating solution (recipe 1)

[0092] 0.5 parts of high-temperature-resistant transparent heat-insulating slurry, wherein the high-temperature-resistant transparent heat-insulating slurry is a propylene glycol methyl ether acetate dispersion of nano-antimony tin oxide (particle size ≤ 100 nanometers), with a solid content of 30%.

Embodiment 2

[0093] Embodiment 2 glass temperable thermal insulation coating

[0094] by weight,

[0095] 1 part temperable coating solution (Recipe 2)

[0096] 1 part of high-temperature-resistant transparent heat-insulating slurry, wherein the high-temperature-resistant transparent heat-insulating slurry is an ethyl acetate dispersion of nano-antimony tin oxide (particle size ≤ 100 nanometers), with a solid content of 30%.

Embodiment 3

[0097] Embodiment 3 glass temperable thermal insulation coating

[0098] by weight,

[0099] 1 part temperable coating solution (Recipe 3)

[0100] 0.1 part of high-temperature-resistant transparent heat-insulating slurry, wherein the high-temperature-resistant transparent heat-insulating slurry is an ethyl acetate dispersion of nanometer antimony tin oxide (particle diameter ≤ 100 nanometers), with a solid content of 30%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com