Blast furnace main iron runner

A technology of main iron trough and blast furnace, which is applied in the direction of blast furnace, blast furnace details, blast furnace parts, etc., and can solve problems such as unadjustable angle and length of tapping trough, uncontrollable flow rate of molten iron, and inconvenience of tapping main trough

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

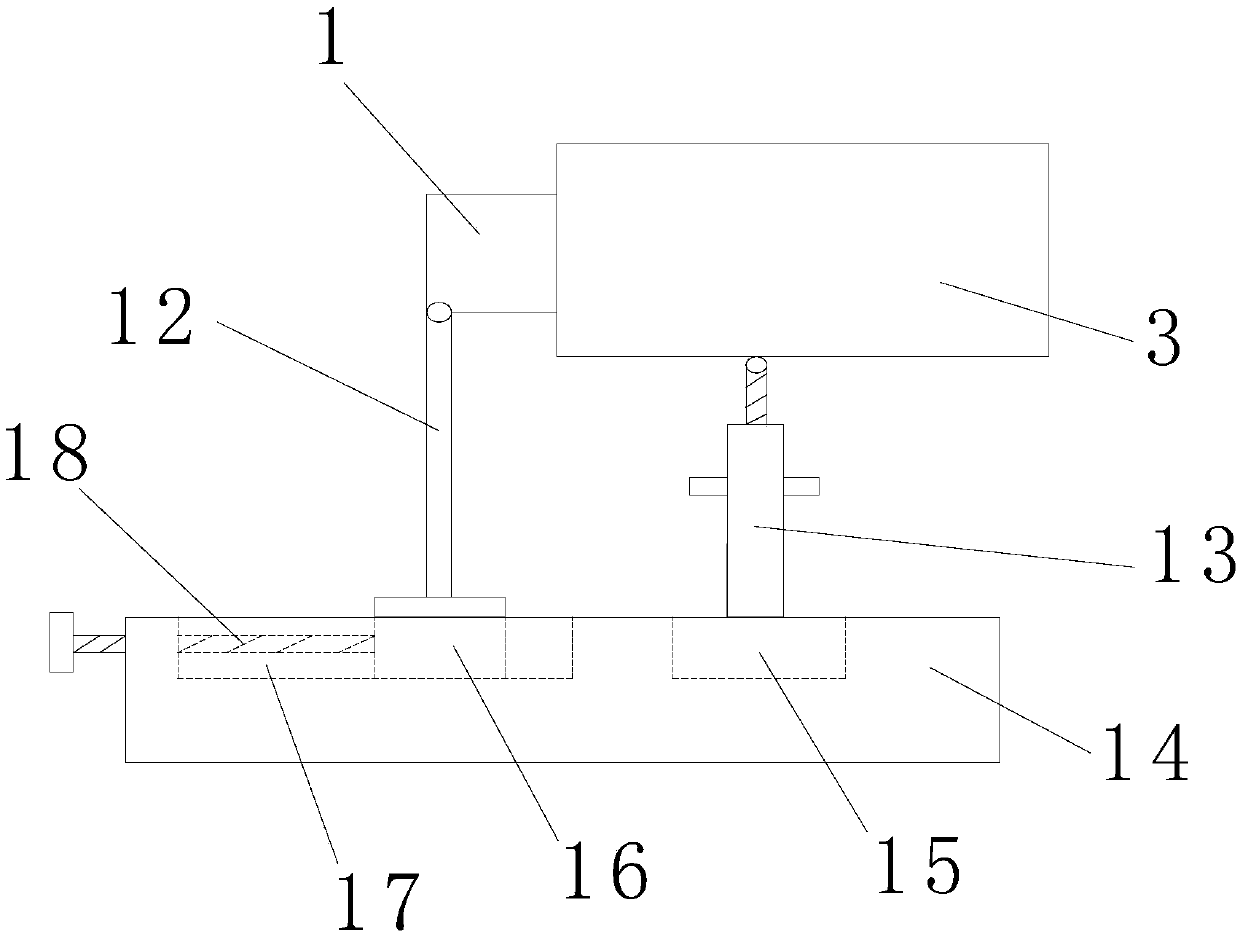

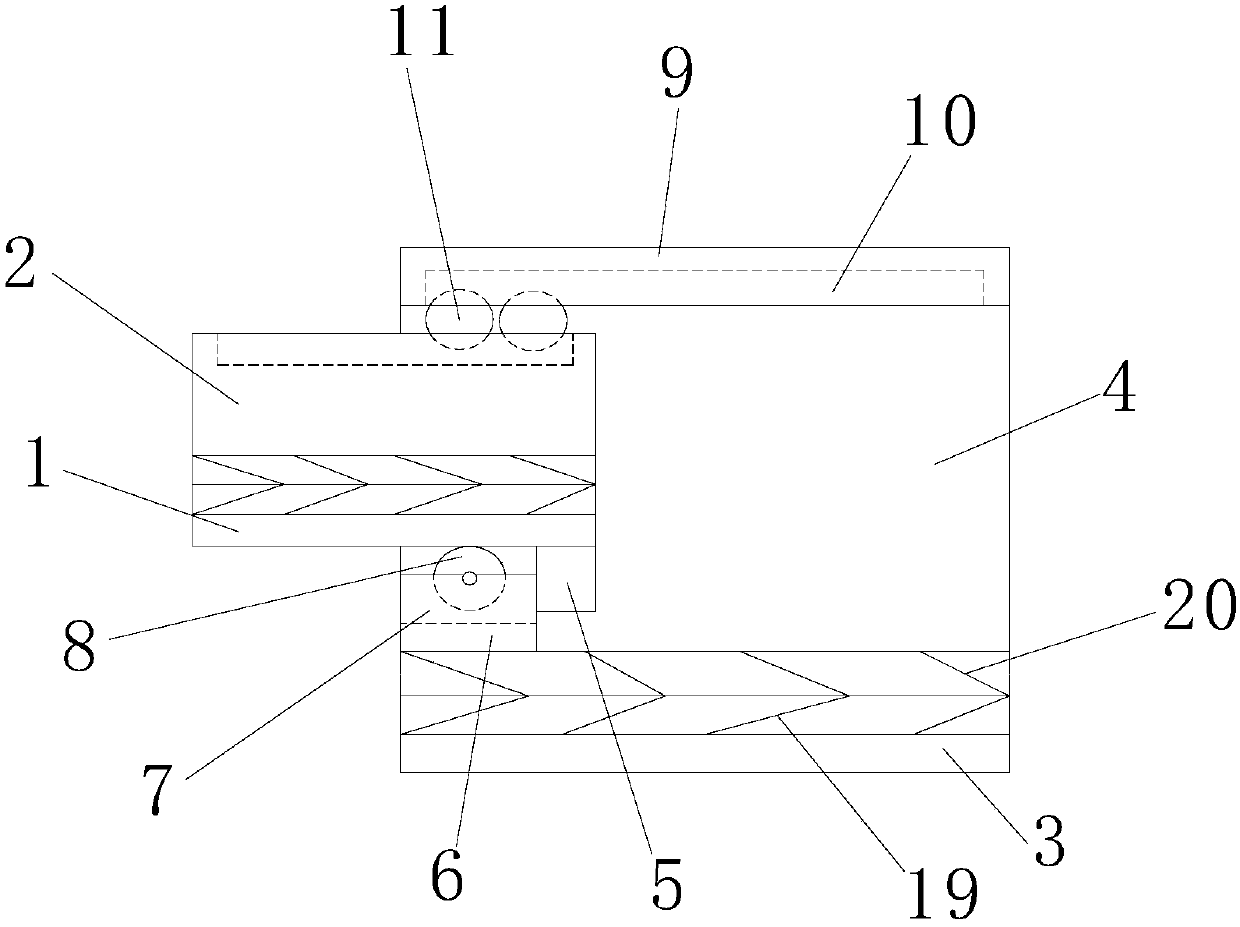

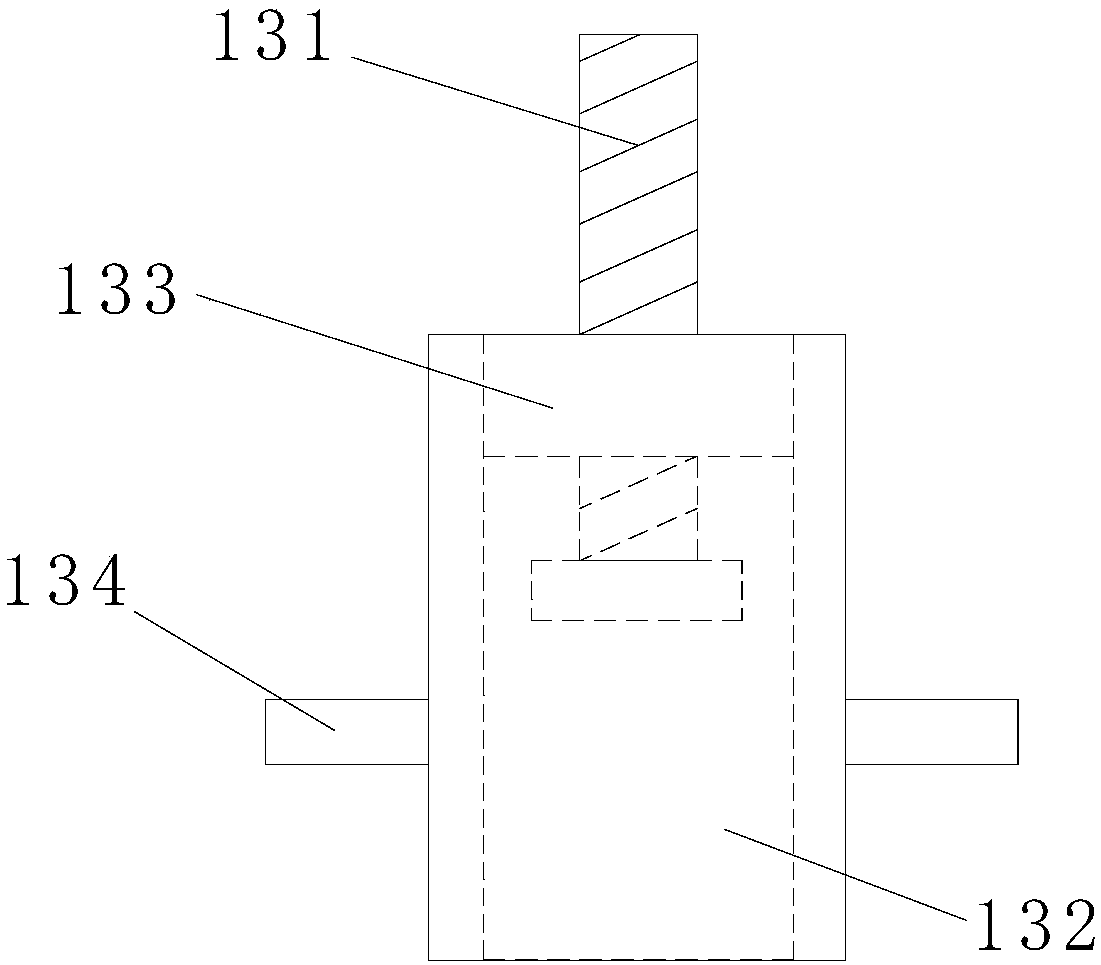

[0018] refer to figure 1 , 2 , 3, a main iron trough of a blast furnace in the present invention, comprising a first main body 1, a first molten iron tank 2, a second main body 3, a second molten iron tank 4, a first stopper 5, a second stopper 6, and an installation groove 7 , roller 8, rib 9, rolling groove 10, rolling ball 11, support rod 12, adjustment rod 13, base 14, bearing 15, slider 16, chute 17, adjustment bolt 18, the upper part of the first main body 1 A first molten iron tank 2 is opened along the length direction, and a second molten iron tank 4 for accommodating the first main body 1 is opened on the upper part of the second main body 3 along the length direction. The right end of the first main body 1 is slidably arranged on the second In the second iron water tank 4, the outer side of the right end of the first main body 1 is fixedly provided with an arc-shaped first stopper 5, and the inner side of the left end of the second iron water tank 4 is fixedly prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com