Device for depositing diamond coating layers and preparation method of deposited diamond coating layers

A diamond coating and double-layer technology, which is applied in the direction of metal material coating process, coating, gaseous chemical plating, etc., can solve the problems of difficult coating, low bonding force of diamond coating, uneven diamond coating, etc. , to achieve the effect of improving the bonding strength and growing the diamond coating uniformly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

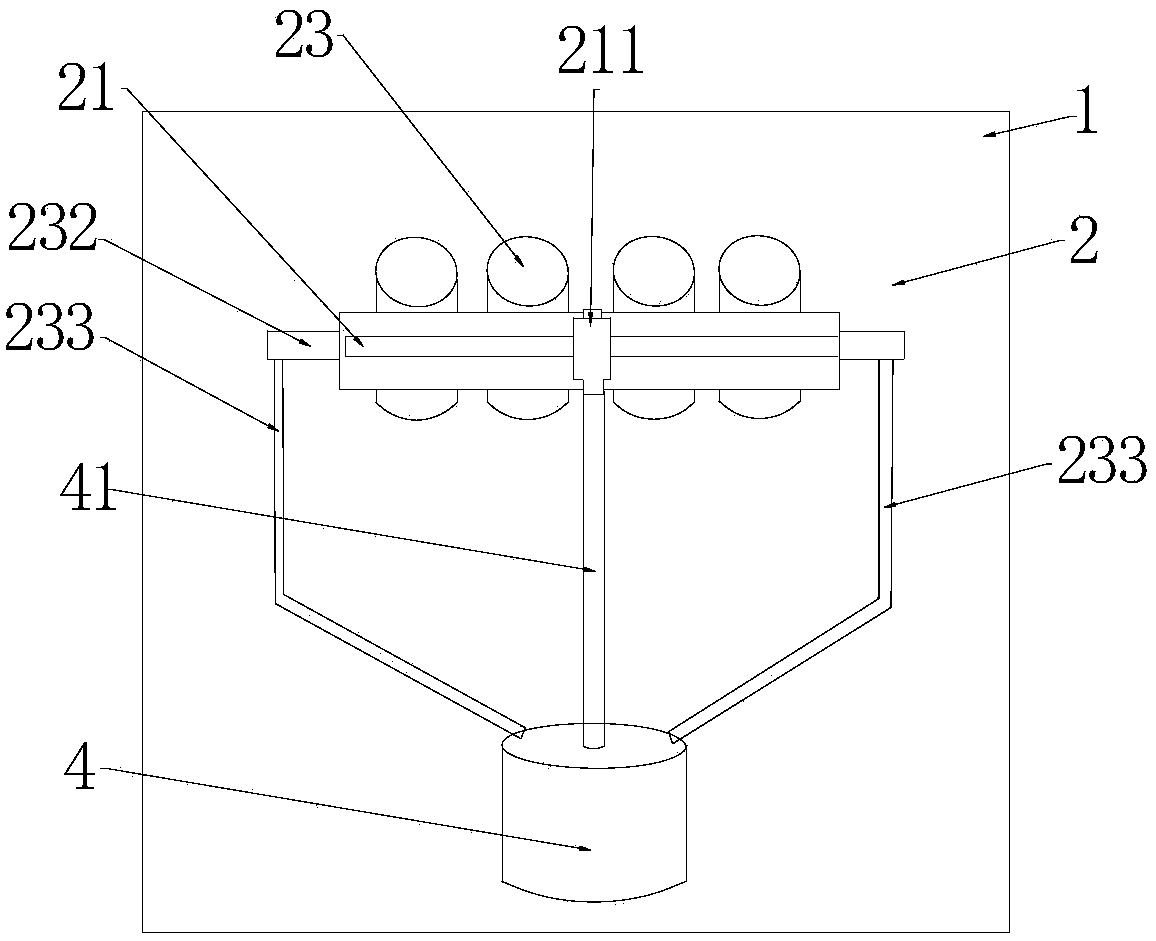

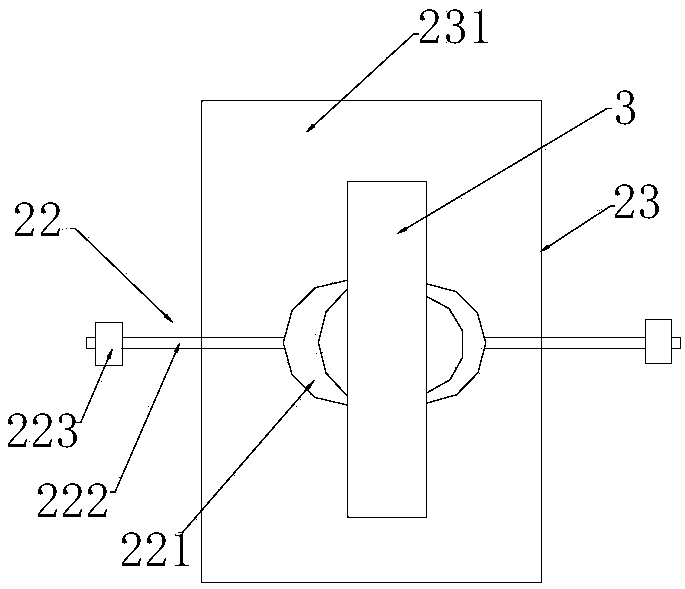

[0031] On the basis of the above-mentioned device for depositing a diamond coating, an embodiment of the present invention also provides a preparation method for depositing a diamond coating. combine figure 1 and 2 , the preparation method of the deposited diamond coating comprises the steps:

[0032] Step S01: Clamp the mold 3 after surface pretreatment and crystal planting treatment on the clamping part 221 contained in the above-mentioned device for depositing the diamond coating;

[0033] Step S02: On the basis of step S01, grow a diamond coating on the surface of the mold 3 according to the method of growing a diamond coating;

[0034] Step S03: On the basis of step S02, drive the transmission rod 21 contained in the device to rotate or move, thereby driving the clamping part 221 contained in the clamp 22 to rotate, so that the mold 3 is turned over, And continue to grow the diamond coating on the surface of the mold 3 .

[0035] Wherein, the surface pretreatment in s...

Embodiment 1

[0053] This embodiment provides a method for preparing a diamond coating in the inner hole of a micro-hole wire drawing die. The method comprises the steps of:

[0054] Step S1: Clean the drawing die, first use deionized water to ultrasonically clean twice, each time for 5 minutes, and finally use acetone to ultrasonically clean for 5 minutes, and blow dry with nitrogen;

[0055] Step S2: corroding the cleaned wire drawing die to increase the surface roughness, improve the interlocking ability of the coating, and remove a certain amount of cobalt. Corrosion treatment is ultrasonic cleaning in alkaline solution for 3 minutes, and then cleaning in acid solution for 20 seconds; among them, the alkaline solution is: 5gK 3 [Fe(CN)] 6 +5gKOH+50mlH 2O, the acid solution is: 10mlH 2 SO 4 +100mlH 2 o 2 .

[0056] Step S3: cleaning the wire drawing die, and cleaning the corrosion solution remaining in the cemented carbide. Use deionized water to ultrasonically clean twice, each...

Embodiment 2

[0060] This embodiment provides a method for preparing a diamond coating in the inner hole of a micro-hole wire drawing die. The method comprises the steps of:

[0061] Step S1: Clean the drawing die, first use deionized water to ultrasonically clean twice, each time for 5 minutes, and finally use acetone to ultrasonically clean for 5 minutes, and blow dry with nitrogen;

[0062] Step S2: corroding the cleaned wire drawing die to increase the surface roughness, improve the interlocking ability of the coating, and remove a certain amount of cobalt. Corrosion treatment is ultrasonic cleaning in alkaline solution for 3 minutes, and then cleaning in acid solution for 20 seconds; among them, the alkaline solution is: 5gK 3 [Fe(CN)] 6 +5gKOH+50mlH 2 O, the acid solution is: 10mlH 2 SO 4 +100mlH 2 o 2 ;

[0063] Step S3: Clean the wire drawing die, clean the corrosive solution remaining in the cemented carbide, use deionized water to ultrasonically clean twice, each time for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com