Intercooling control system and method of diesel engine

A control system and control method technology, applied in engine control, electrical control, fuel injection control, etc., can solve problems such as inaccurate intake air flow measurement, and achieve the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

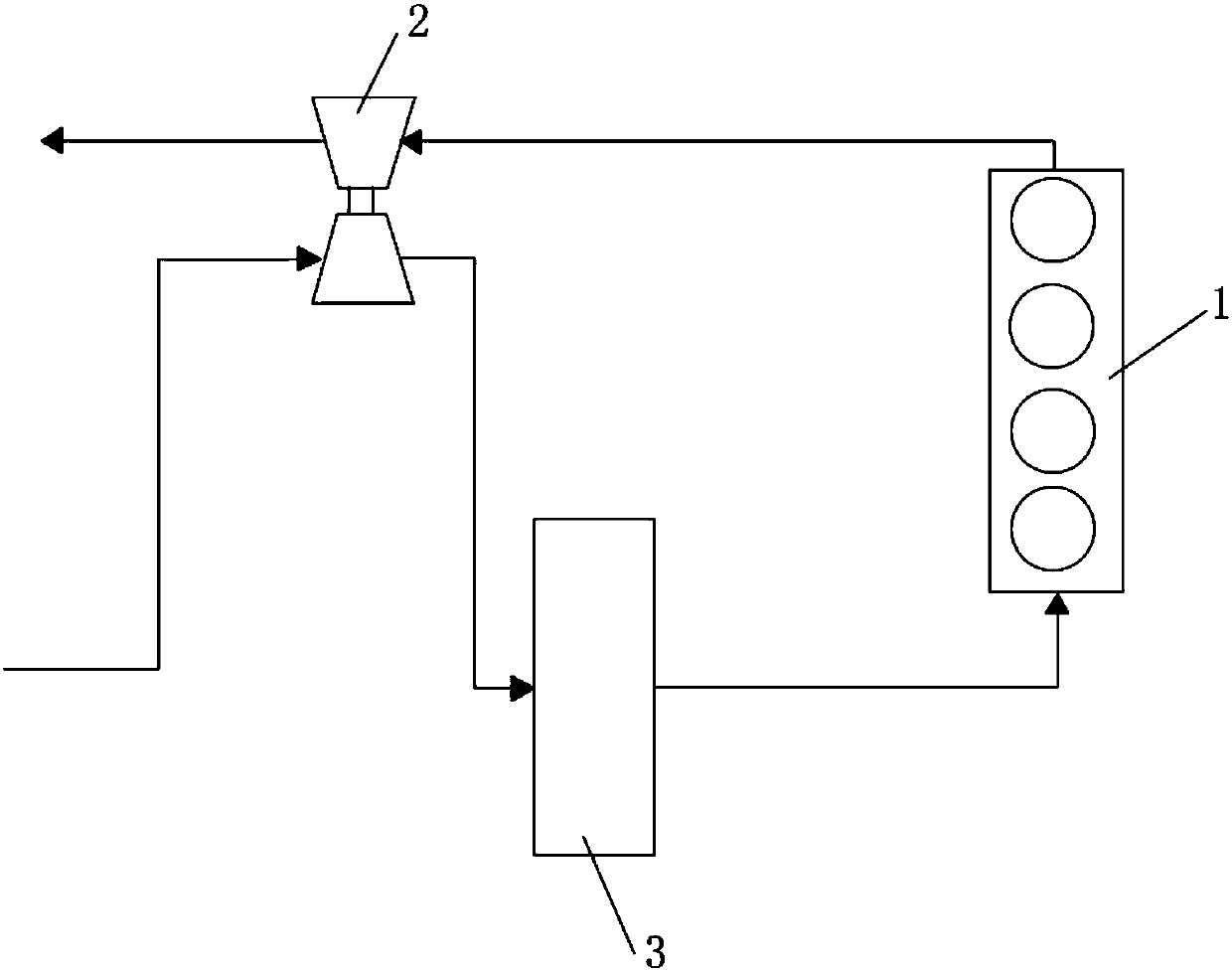

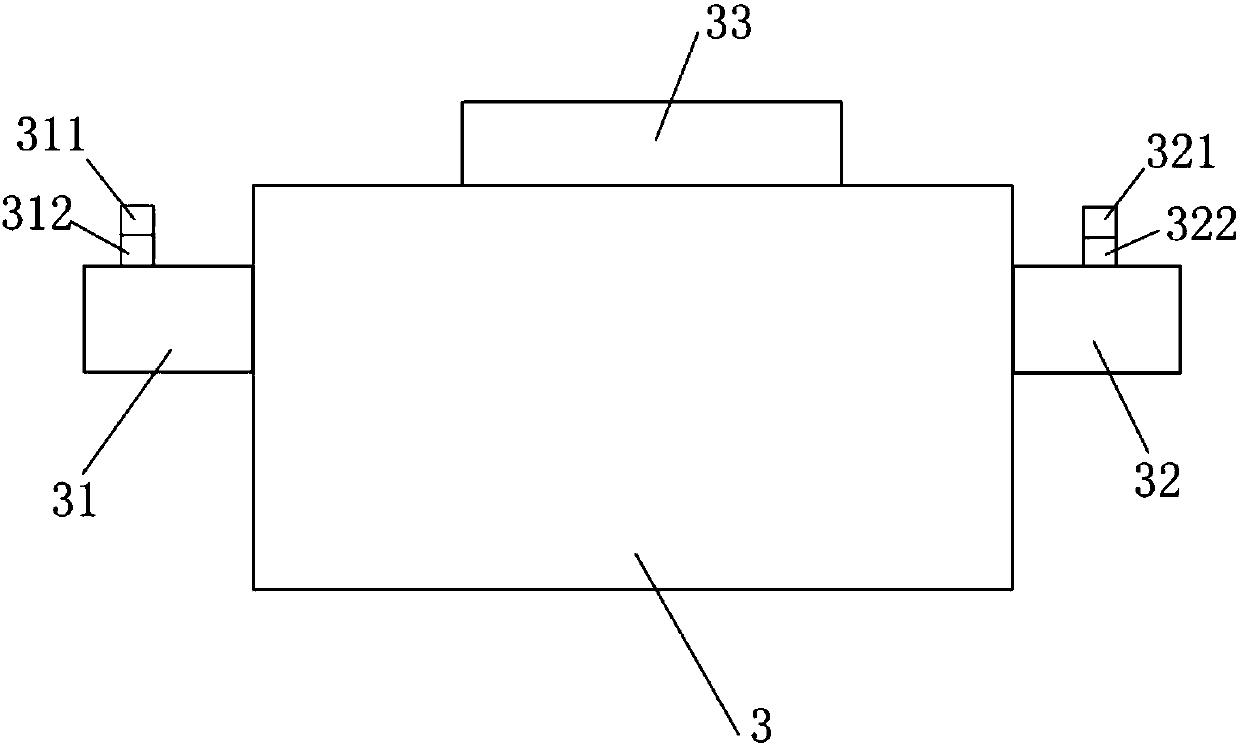

[0041] Such as figure 1 and figure 2 As shown, the present embodiment provides an intercooling control system for a diesel engine, including an engine 1, a turbocharger 2 and an intercooler 3, the exhaust channel of the engine 1 is connected with the exhaust gas inlet of the turbocharger 2, and the turbocharger The air outlet of the compressor 2 is connected to the air inlet of the intercooler 3, and the air outlet of the intercooler 3 is connected to the intake passage of the engine 1; the intercooler 3 is integrated with a front straight pipe section 31 and / or a rear straight pipe section 32 , the front straight pipe section 31 is provided with a first pressure sensor 311 and a first temperature sensor 312, or the rear straight pipe section 32 is provided with a second pressure sensor 321 and a second temperature sensor 322, and the intercooler 3 is also integrated with data processing Unit 33, the data processing unit 33 has the functions of data acquisition, data process...

Embodiment 2

[0053]This embodiment provides an intercooler control system for a diesel engine. For simplicity, only the differences from Embodiment 1 will be described. The difference is that, in this embodiment, the front straight pipe section 31 is provided with a first pressure sensor 311 and a first temperature sensor 312 , and the rear straight pipe section 32 is provided with a second pressure sensor 321 and a second temperature sensor 322 .

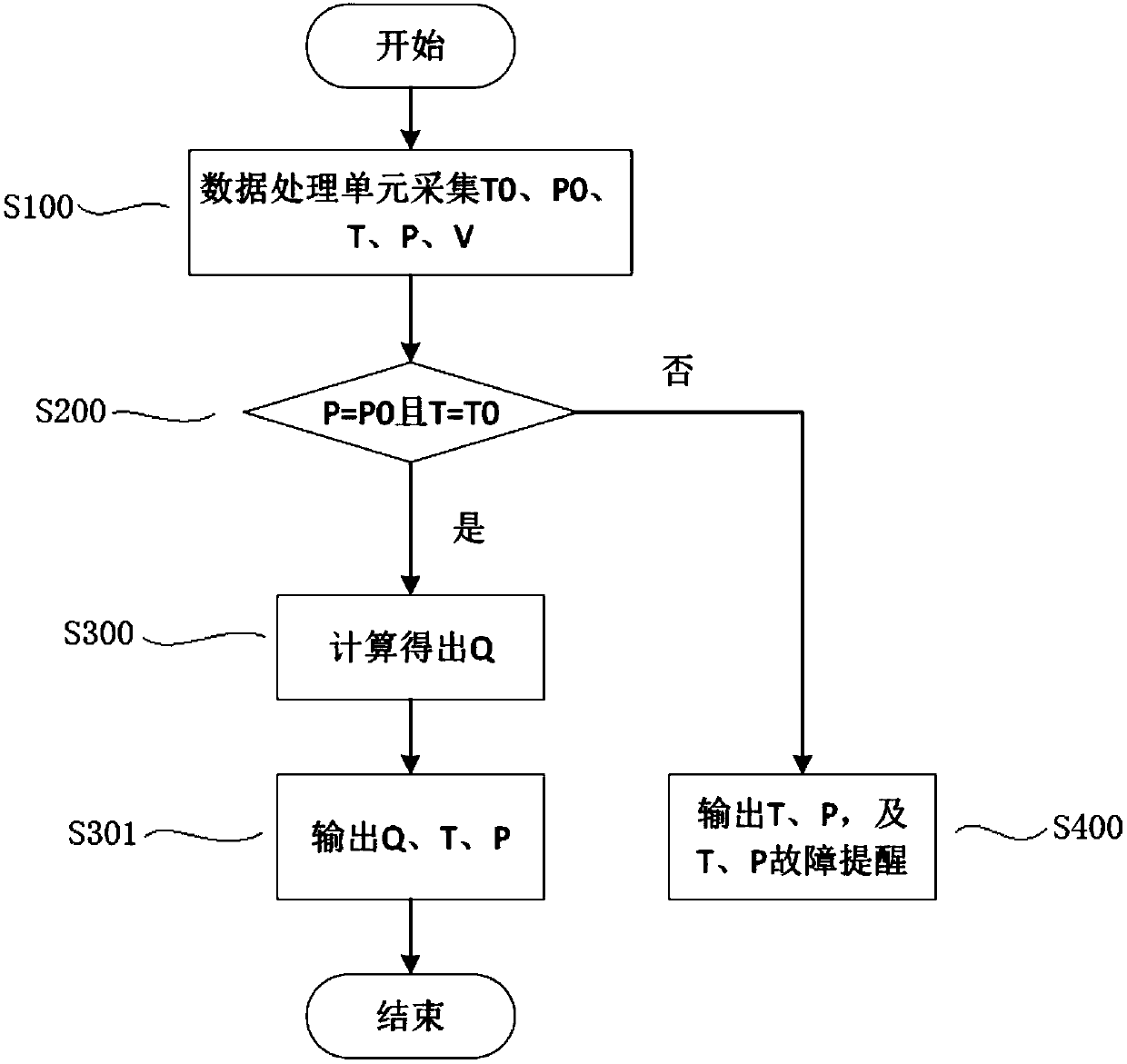

[0054] Such as Figure 4 As shown, the control method of the intercooling control system of the diesel engine provided in this embodiment is as follows:

[0055] It should be noted in advance that steps S100 and S200 occur when the engine is not started, and steps S300, S301, S400, S401, S501 and S600 occur after the engine is started.

[0056] S100, the data processing unit 33 collects the temperature value T1 of the first temperature sensor 312, the pressure value P1 of the first pressure sensor 311, the temperature value T2 of the second te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com