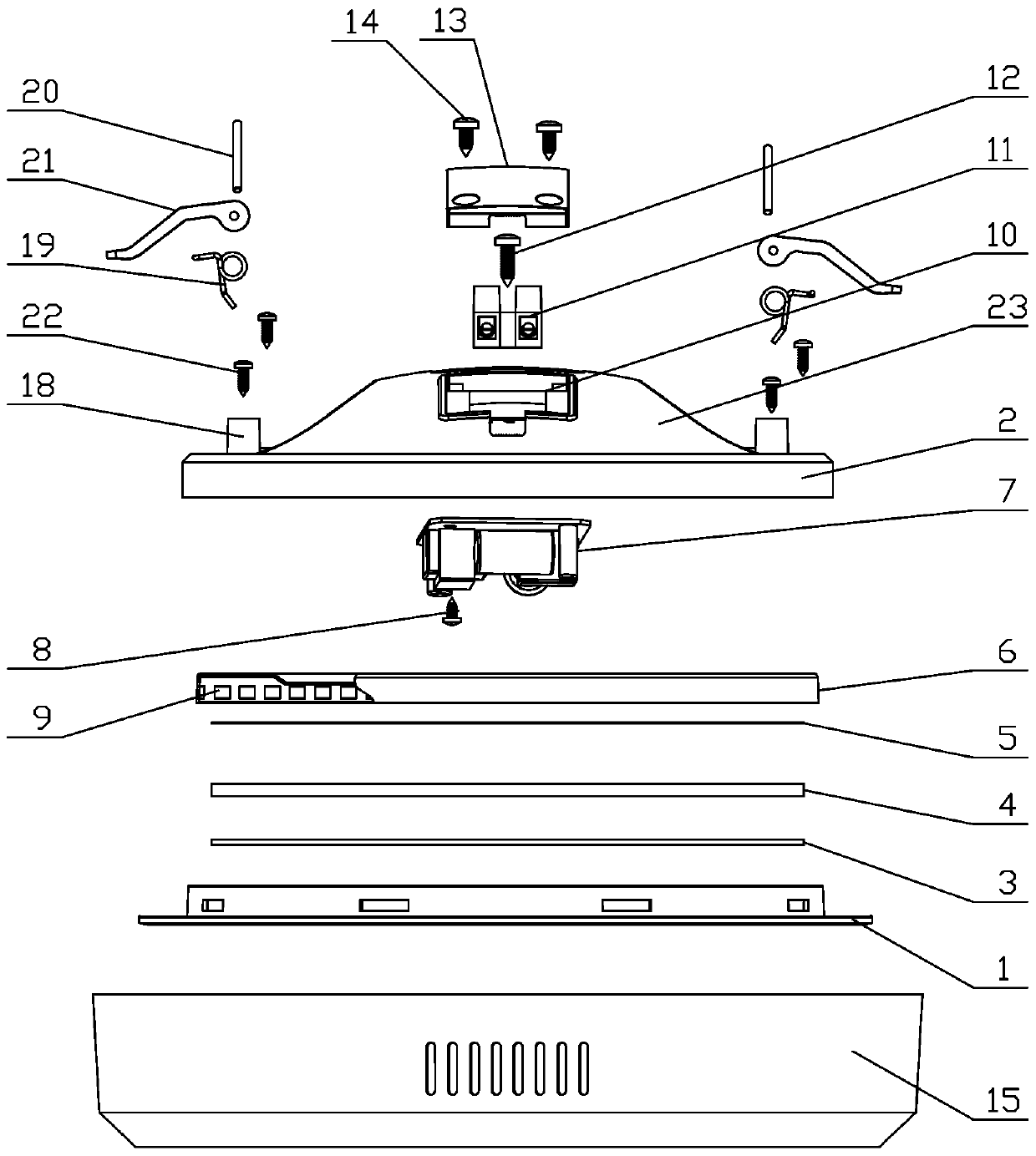

LED side light-emitting panel lamp with built-in driver

A panel light, side-emitting technology, applied in the direction of light guide, optics, light guide, etc. of lighting devices, can solve the problems of power cord, drive casing and drive damage, low safety protection level, and panel lights cannot be used universally, etc. It is easy to install and transport, Reduced size and weight, overall aesthetic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

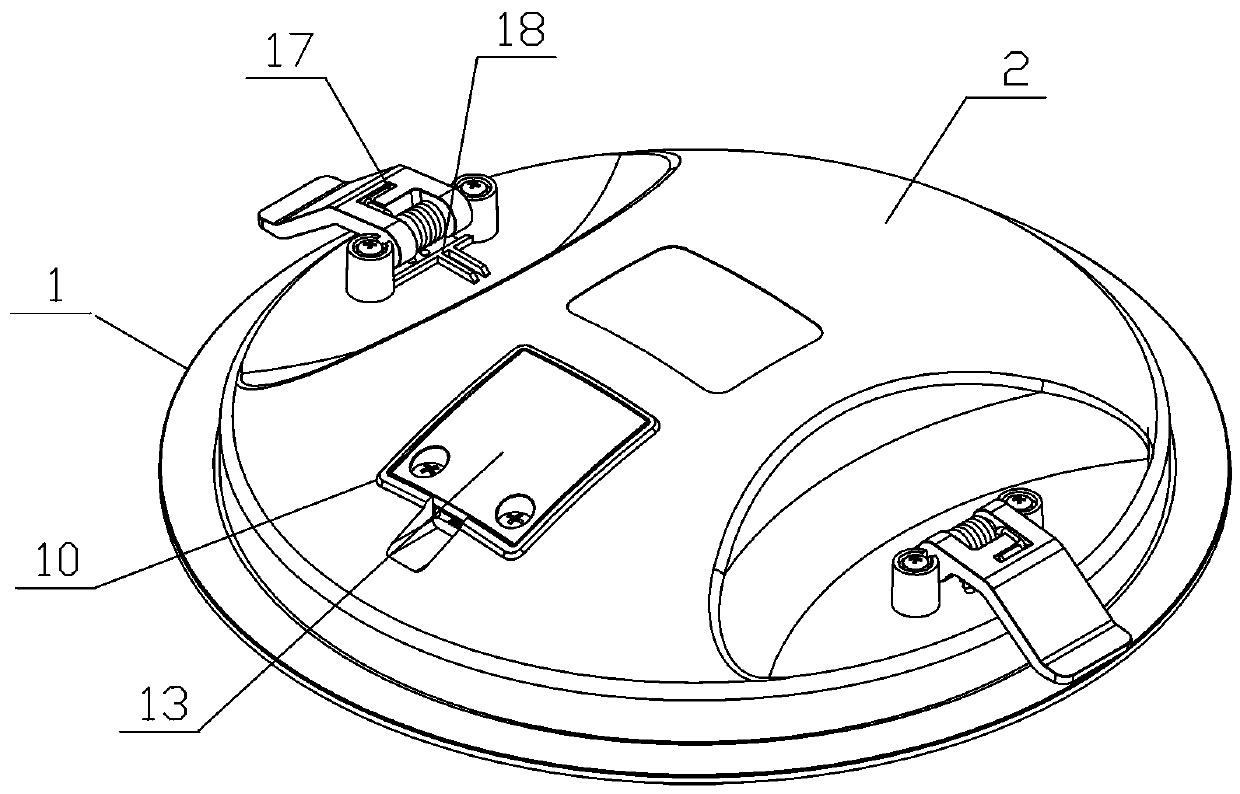

[0032] Example one: such as figure 2 As shown, the plastic face frame 1 can be designed as a circular plastic face frame 1, and the shapes of the plastic bottom shell 2, the light diffusion plate 3, the light guide plate 4, the PET reflective paper 5, and the heat dissipation aluminum plate 6 are all matched with it.

Embodiment 2

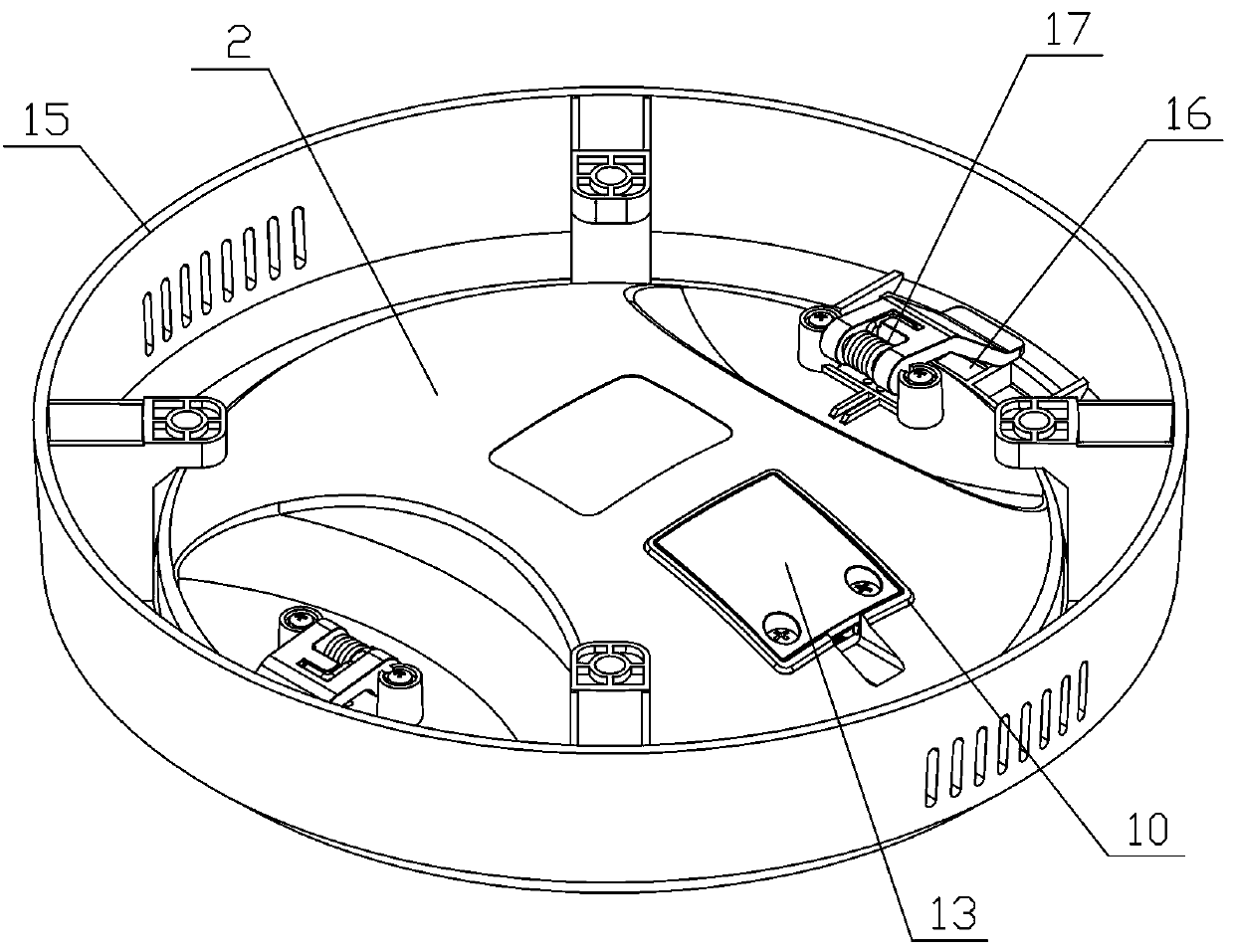

[0033] Embodiment two: such as image 3 As shown, the plastic face frame 1 can be designed as a circular plastic face frame 1, the shape of the plastic bottom shell 2, the light diffusion plate 3, the light guide plate 4, the PET reflective paper 5, the heat dissipation aluminum plate 6, and the ceiling exposed frame 15 All cooperate with it.

Embodiment 3

[0034] Embodiment 3: The plastic face frame 1 can be designed as a square plastic face frame 1, and the shapes of the plastic bottom shell 2, the light diffusion plate 3, the light guide plate 4, the PET reflective paper 5, and the heat dissipation aluminum plate 6 are all matched with it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com