Micro voltage high overload sensor chip

A sensor chip, high overload technology, applied in instruments, measuring fluid pressure, measuring fluid pressure through electromagnetic components, etc., can solve the problem of contradiction between sensitivity and overload impedance, and achieve the effect of improving strain and sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

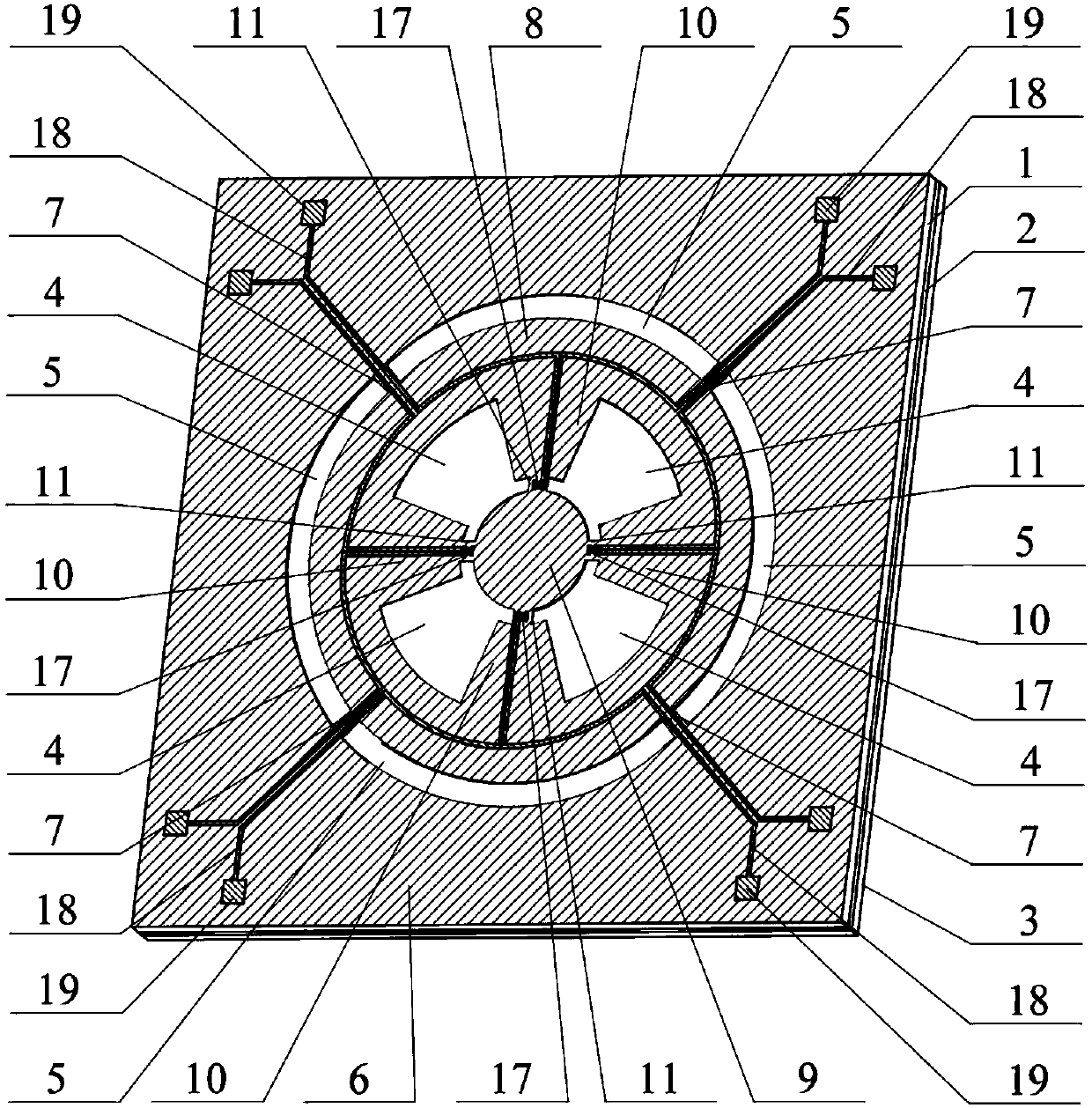

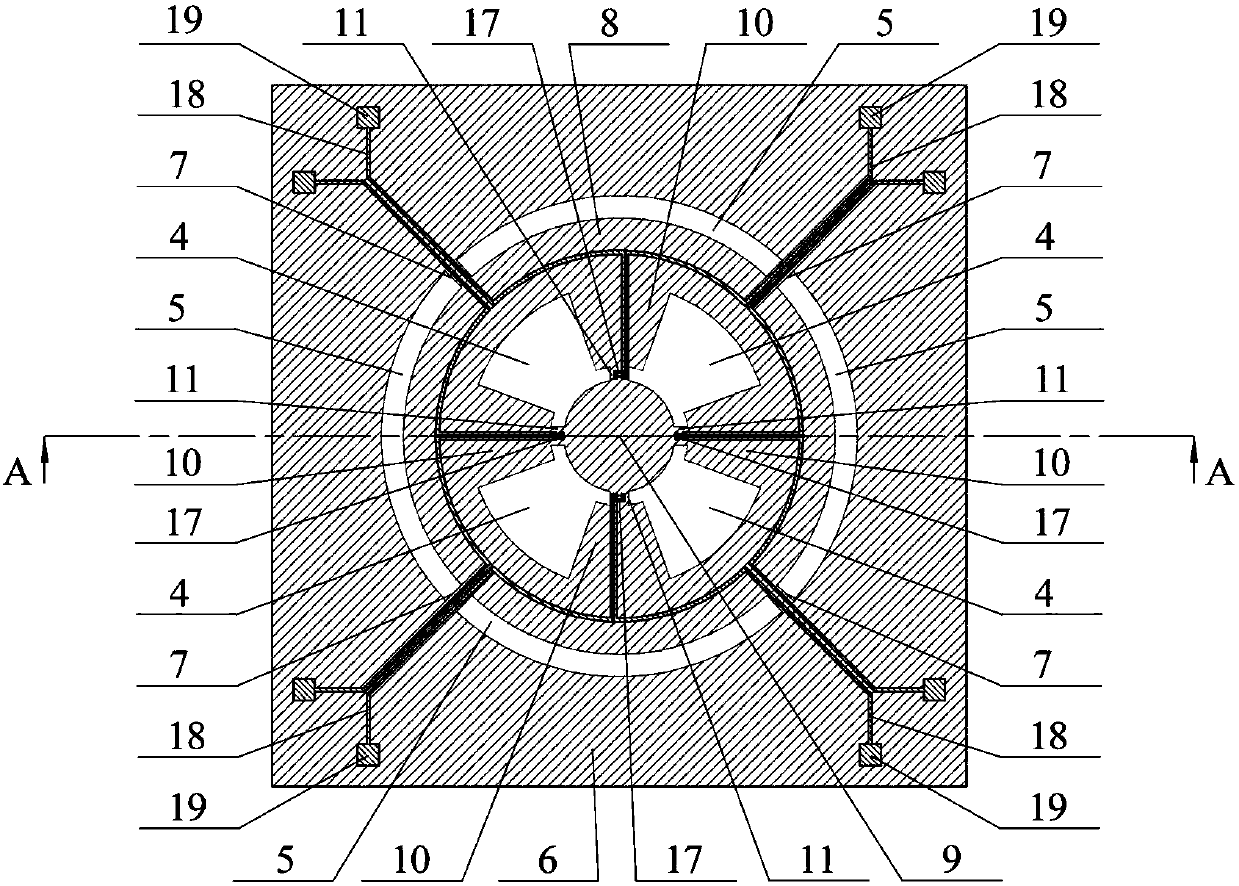

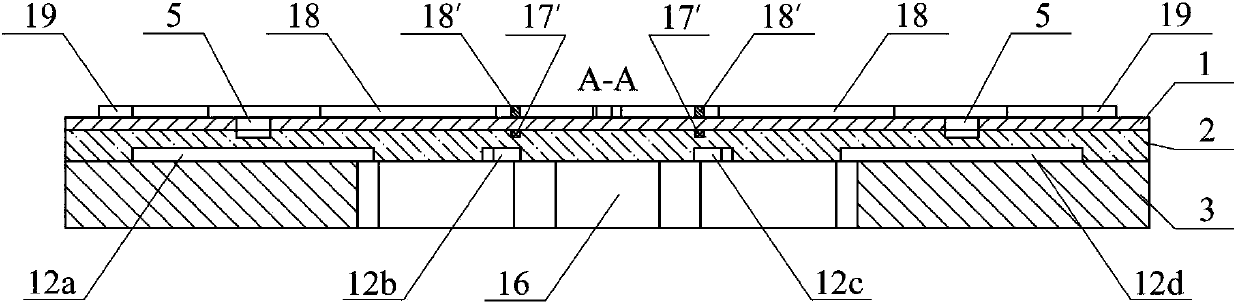

[0042] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

[0043] refer to Figure 1 to Figure 6 , In this embodiment, a micro-voltage high overload sensor chip is provided. The sensor chip includes a substrate 3, a device layer 2 and an oxide layer 1 stacked in sequence from bottom to top, and the three form an integrated device. It should be noted that the micro pressure range referred to here is 0-500Pa; the high overload range referred to here is 200-500 times the full scale. The ranges of micro-pressure and high-overload specified here can be used as reference, and the specific ranges known to those skilled in the art shall prevail.

[0044] Wherein, the oxide layer 1 is a silicon dioxide insulating layer; the material of the device layer 2 is single crystal silicon; the material of the substrate 3 is preferably...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com