Tool path generating method of propeller blade processing

A propeller and tool path technology, which is applied in the field of tool path trajectory generation for machining propeller blades by CNC machine tools, can solve problems such as multiple tool paths, and achieve the effect of reducing processing costs and high automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In the present invention, firstly, the curved surface of the propeller blade is divided into pieces to obtain several sub-curved surfaces. Secondly, the tool path planning is carried out for each sub-surface. In the process of tool path planning for each sub-surface, the appropriate tool-feeding direction, line spacing direction, line spacing and step accuracy are selected to generate the tool contact trajectory of each surface and Calculate and generate tool point trajectory. Finally, supplementary processing is performed on the boundary part of each sub-surface. The specific implementation steps are as follows:

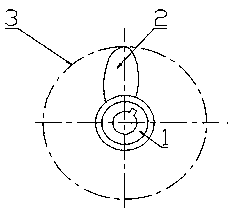

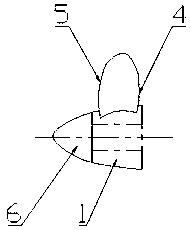

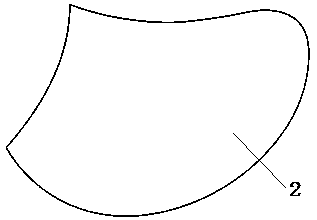

[0030] Such as image 3 with Figure 4 As shown, first of all, for image 3 The blade surface 2 of the propeller blade is segmented, and the blade surface 2 of the propeller blade is divided into different sub-surface areas processed by numerical control. When the sub-surface area is segmented, the concavity and convexity of each point in each sub-surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com