Hierarchical system integration design modeling method

A system integration and modeling method technology, applied in the field of hierarchical system integration design and modeling, can solve problems such as single goal and lack of description model, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

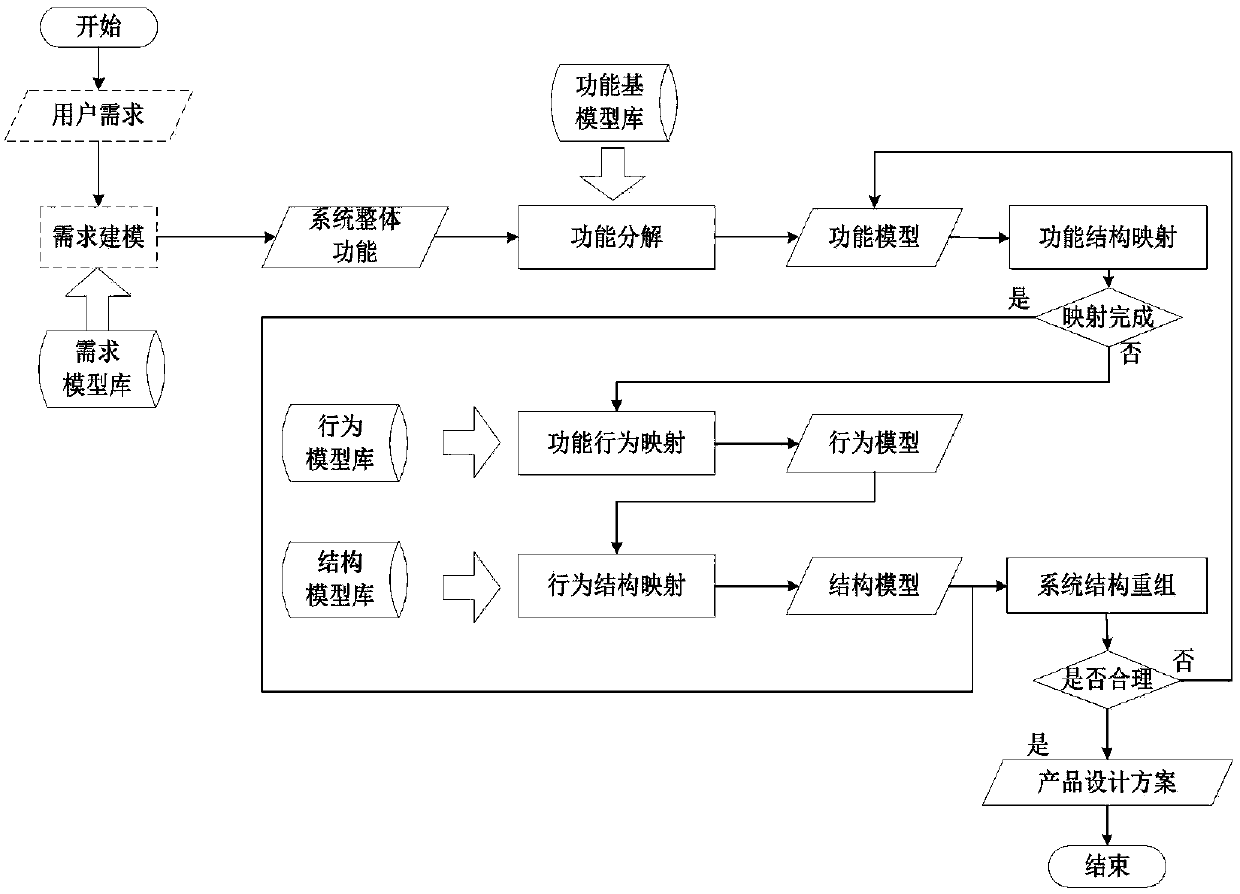

[0032] Specific implementation mode one: combine figure 1 As shown, this embodiment is a hierarchical system integration design modeling method, including the following steps:

[0033] Pre-defined steps of conceptual design model library: according to the design tasks of product systems in different disciplines, construct and import the required model library, function model library, behavior model library and structure model library, and use SysML to graphically express the model library;

[0034] The steps of requirements classification modeling: graphical modeling of system requirements from the overall perspective of the system;

[0035] The steps of functional requirements analysis based on use cases: From the perspective of users, identify the main functions of the product through use case analysis and define the system boundaries;

[0036] Steps of system function modeling: Designers analyze and confirm the type and quantity of input and output streams for specific sit...

specific Embodiment approach 2

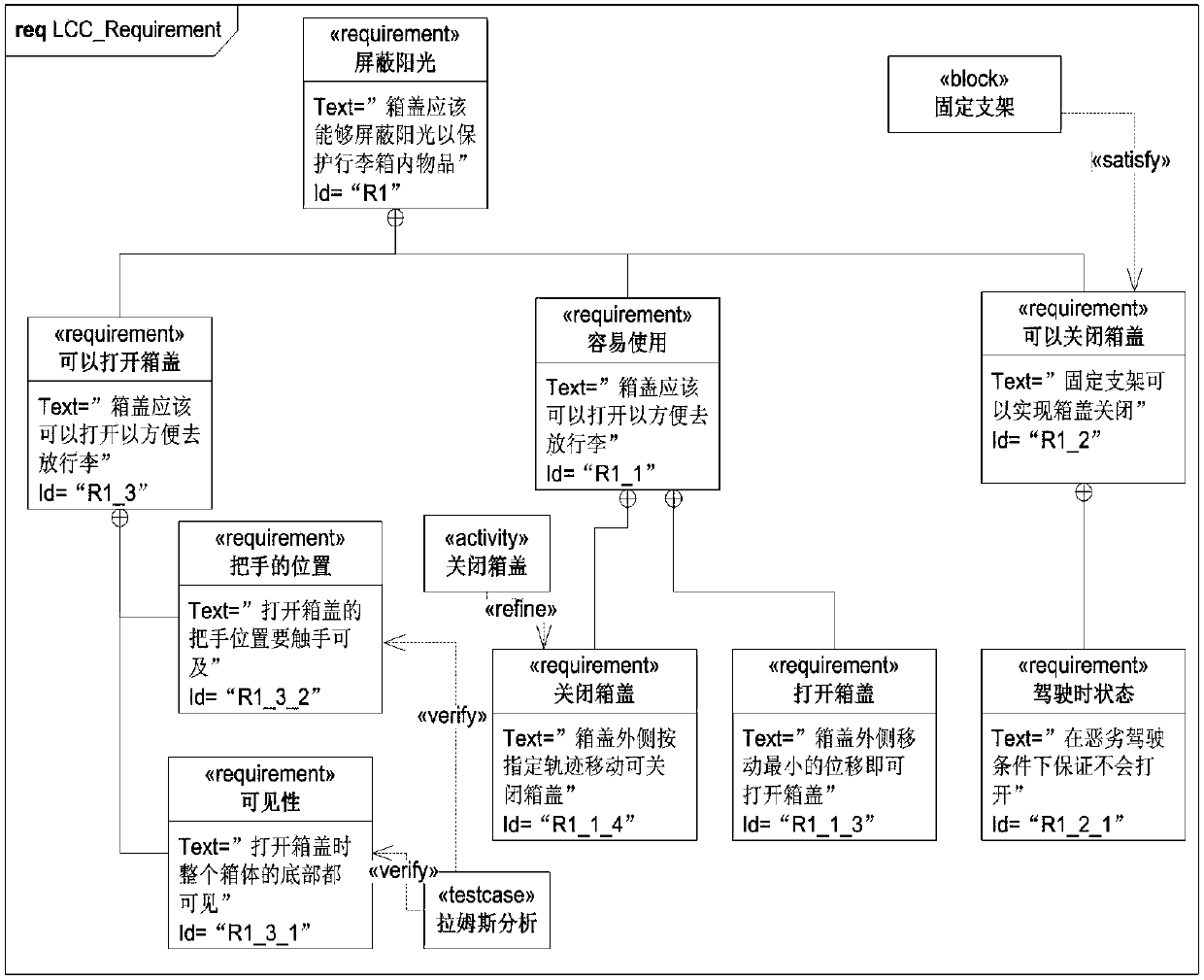

[0038] Embodiment 2: This embodiment is a further limitation of Embodiment 1, wherein the steps of constructing and importing the demand model library used according to the design tasks of product systems in different disciplines are:

[0039] Model the document-style requirements described in natural language, directly build a requirement model library in a modeling tool that supports SysML language, and classify and store the requirement model library in the form of packages according to functional requirements, operation requirements, performance requirements, and interface requirements In a separate format-specific file, each requirement element is represented by two basic attributes "Id" and "Text".

specific Embodiment approach 3

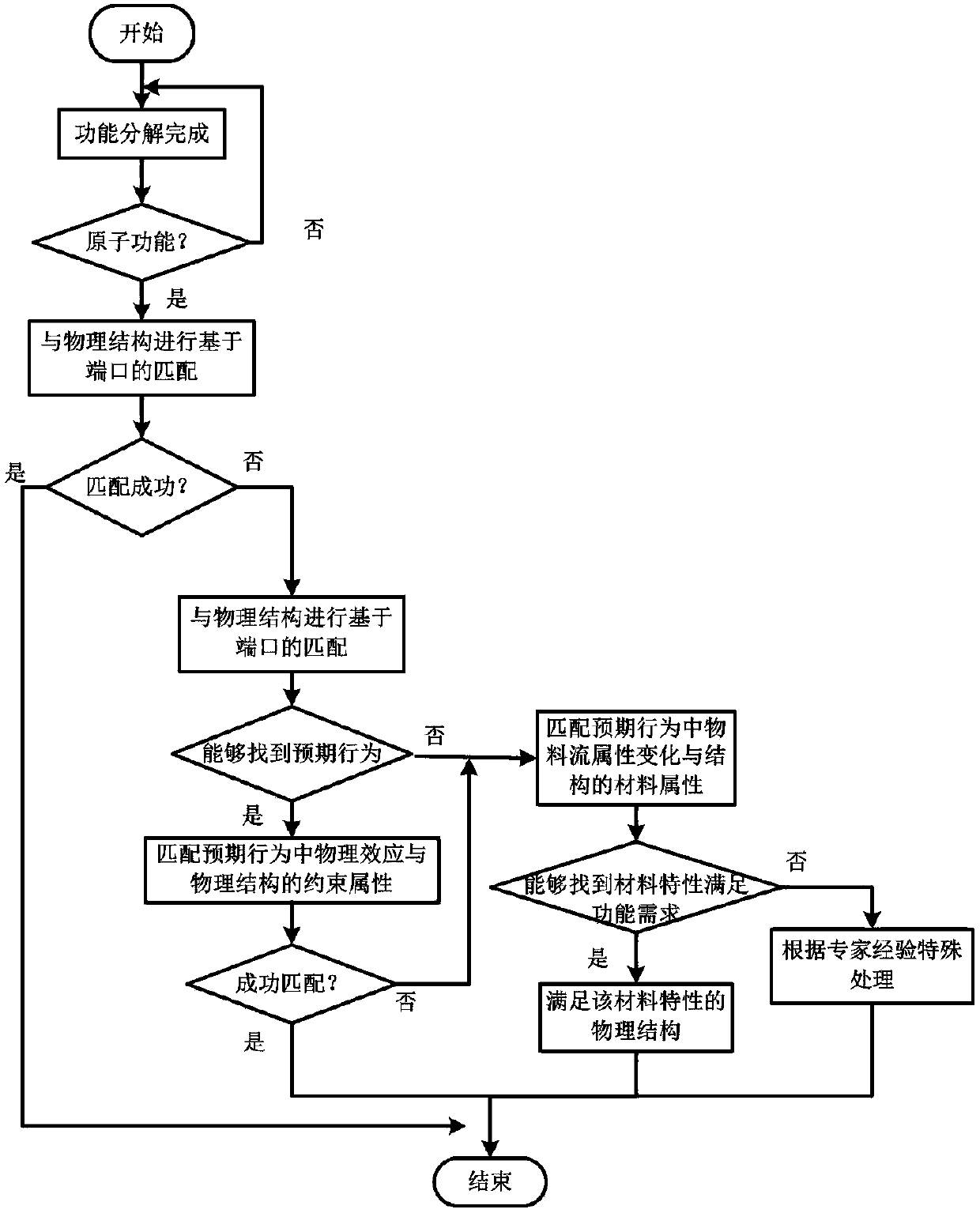

[0040] Embodiment 3: This embodiment is a further limitation of Embodiment 2, wherein the steps of constructing and importing the functional model library used according to the design tasks of product systems in different disciplines are as follows:

[0041] Decompose the basic atomic function into a four-tuple, including function ID, input flow f_in, function element p, output flow f_out, and use the function expression of "function element + flow object" to subdivide the function element into a three-layer structure Expressed, the flow is divided into three categories: material, energy and signal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com