Metal-fitting corona onset voltage determination method based on finite-element electric-field simulation

A technology of corona inception voltage and electric field simulation, applied in design optimization/simulation, electrical digital data processing, special data processing applications, etc., to achieve the effect of high test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

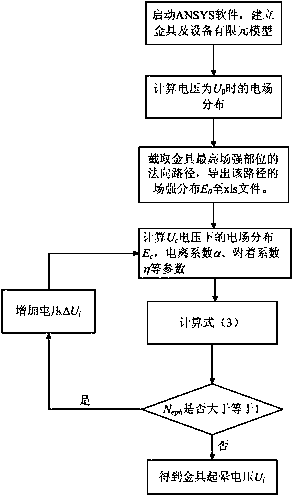

[0026] The specific embodiment of the present invention is as figure 1 shown.

[0027] The steps of the method for determining the corona inception voltage of fittings based on finite element electric field simulation in this embodiment are as follows:

[0028] 1. Start ANSYS software to establish the finite element model of hardware and equipment.

[0029] 2. Calculate the voltage as U 0 electric field distribution at .

[0030] 3. Intercept the normal path of the highest field strength part of the fittings, and derive the field strength distribution E of the path 0 to xls file; E 0 is the field strength in the normal direction, (E 0 / Ec=U 0 / Uc).

[0031] 4. Calculate U C Electric field distribution under voltage E C , ionization coefficient α, adhesion coefficient η and other parameters.

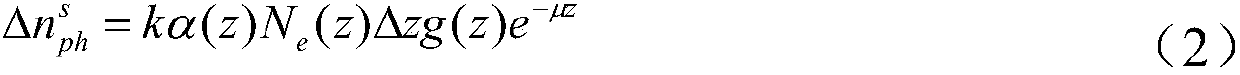

[0032] 5. Calculate

[0033] 6. Judgment N eph Is it greater than or equal to 1, if N eph If less than 1, the corona onset voltage U of the metal fittings can be obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com