Installation shell with cushioning structure and full-lamination liquid crystal display instrument

A fully-fitted, shell technology, applied in the shell with display/control unit, sealed shell, electrical equipment shell/cabinet/drawer, etc. , Poor anti-vertigo effect, lack of effective shock absorption measures for liquid crystal display modules, and the inability of liquid crystal shock absorption sleeves to play a role in shock absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Objects, advantages and features of the present invention will be illustrated and explained by the following non-limiting description of preferred embodiments. These embodiments are only typical examples of applying the technical solutions of the present invention, and all technical solutions formed by adopting equivalent replacements or equivalent transformations fall within the protection scope of the present invention.

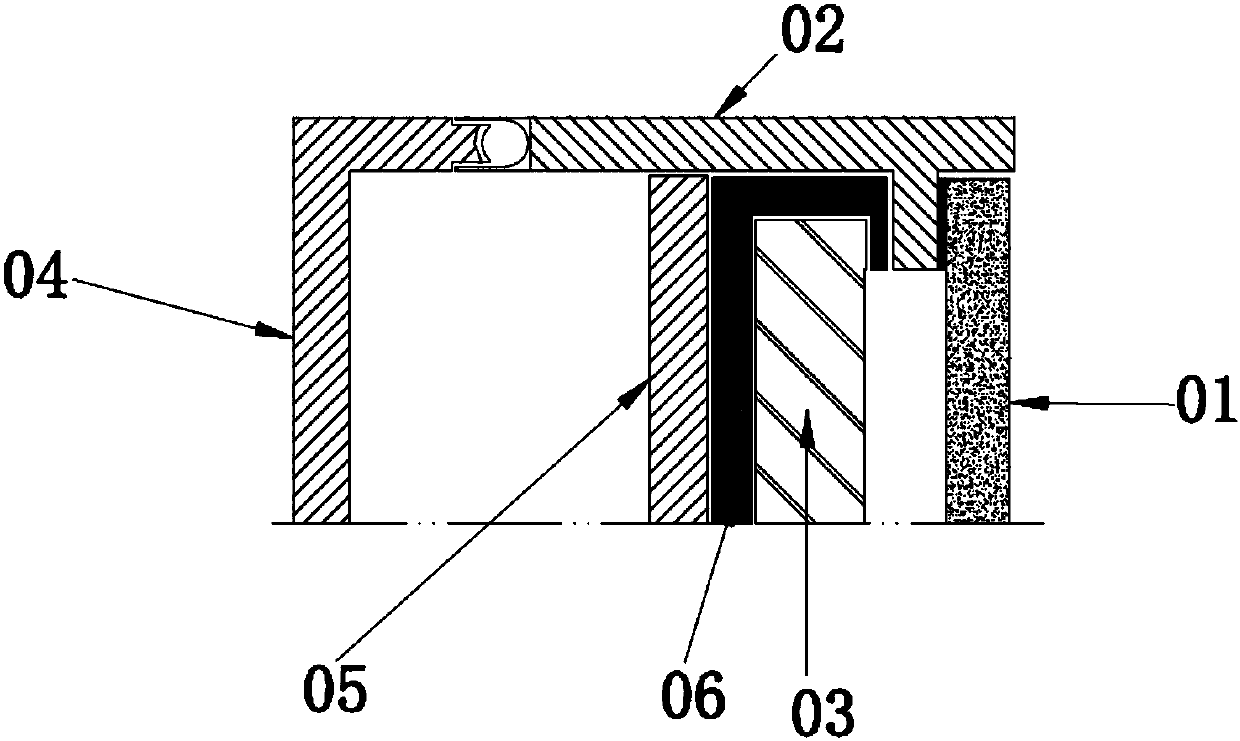

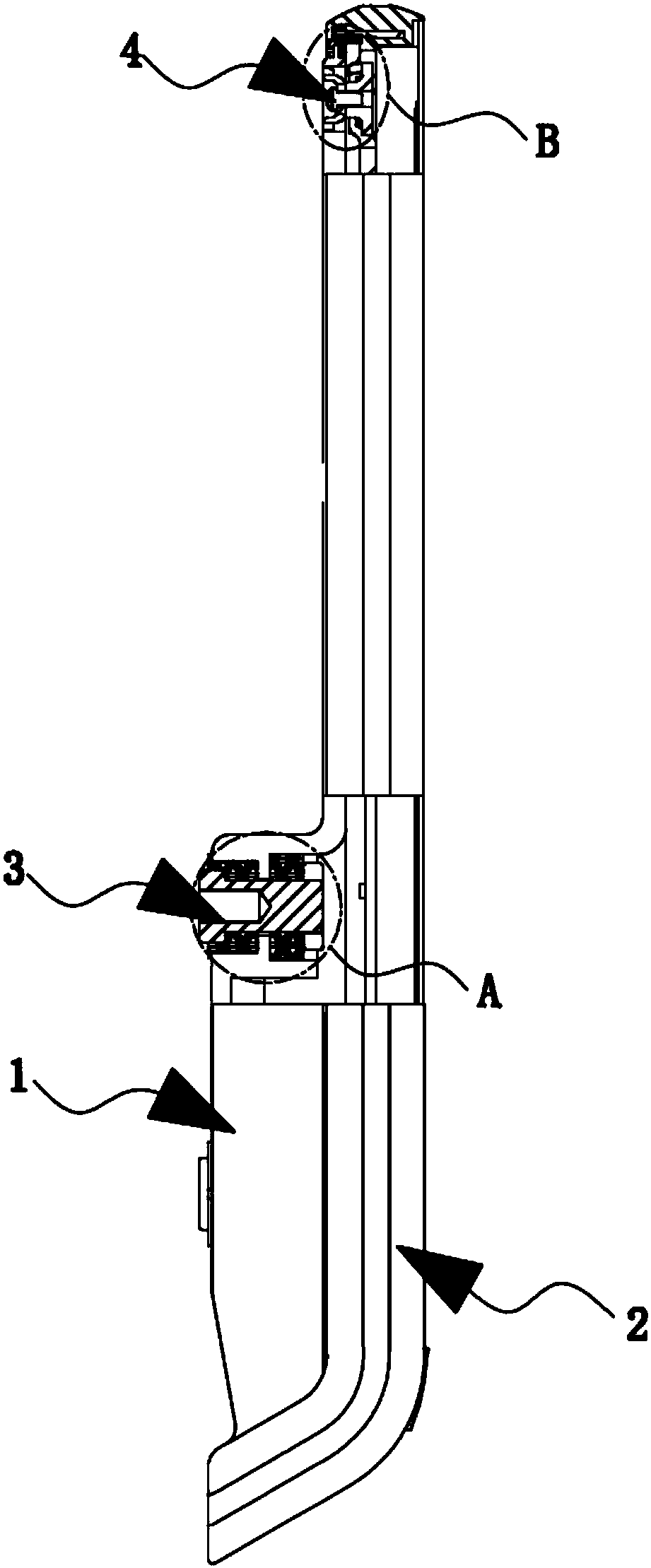

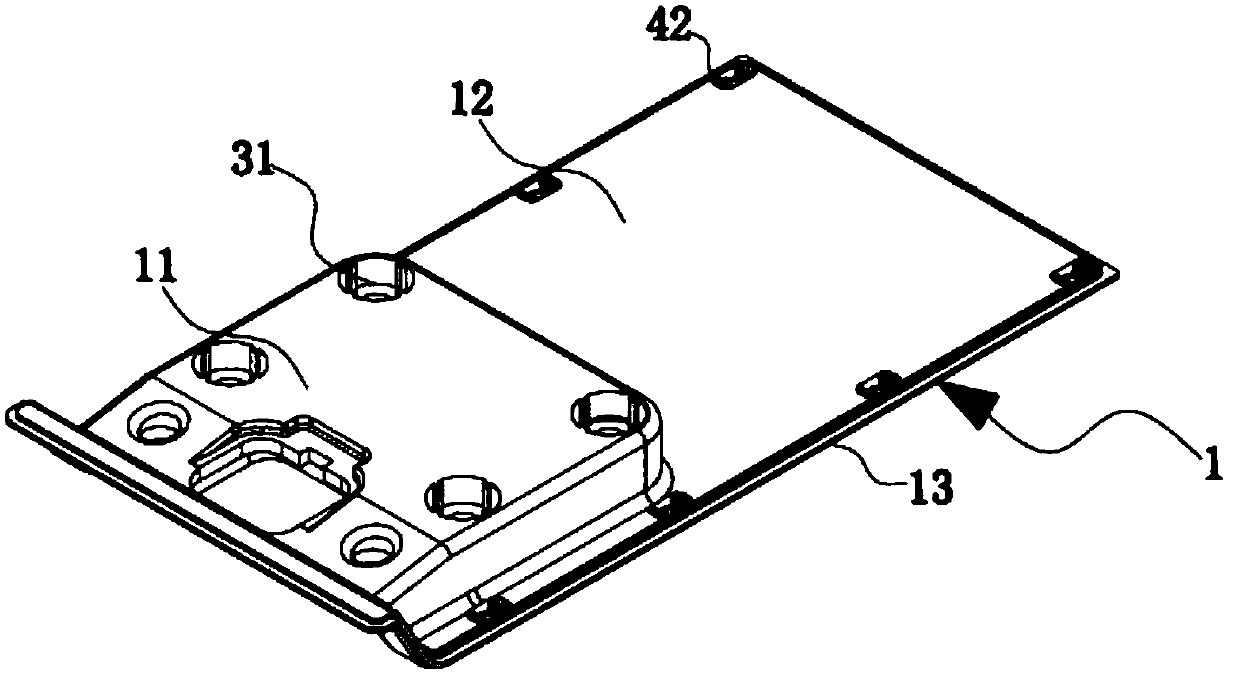

[0045] The present invention discloses a mounting enclosure with a shock-absorbing structure, as attached image 3 - attached Figure 4 As shown, it includes a back cover 1 for connecting a support frame (not shown in the figure) and an upper cover 2 for installing parts to be assembled, the back cover 1 includes a base plate 12, and the base plate 12 includes a flat plate portion and In the curved folded portion, a flange 13 is formed on the side wall of the base plate 12 , and a boss 11 is provided on the end face of the base plate 12 facing away ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com