Biological tissue grinding device

A biological tissue and grinder technology, applied in the field of biomedicine, can solve the problems of long sterilization cycle, easy occurrence of danger, low grinding efficiency, etc., so as to avoid sample loss and pollution, ensure grinding effect, and improve grinding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

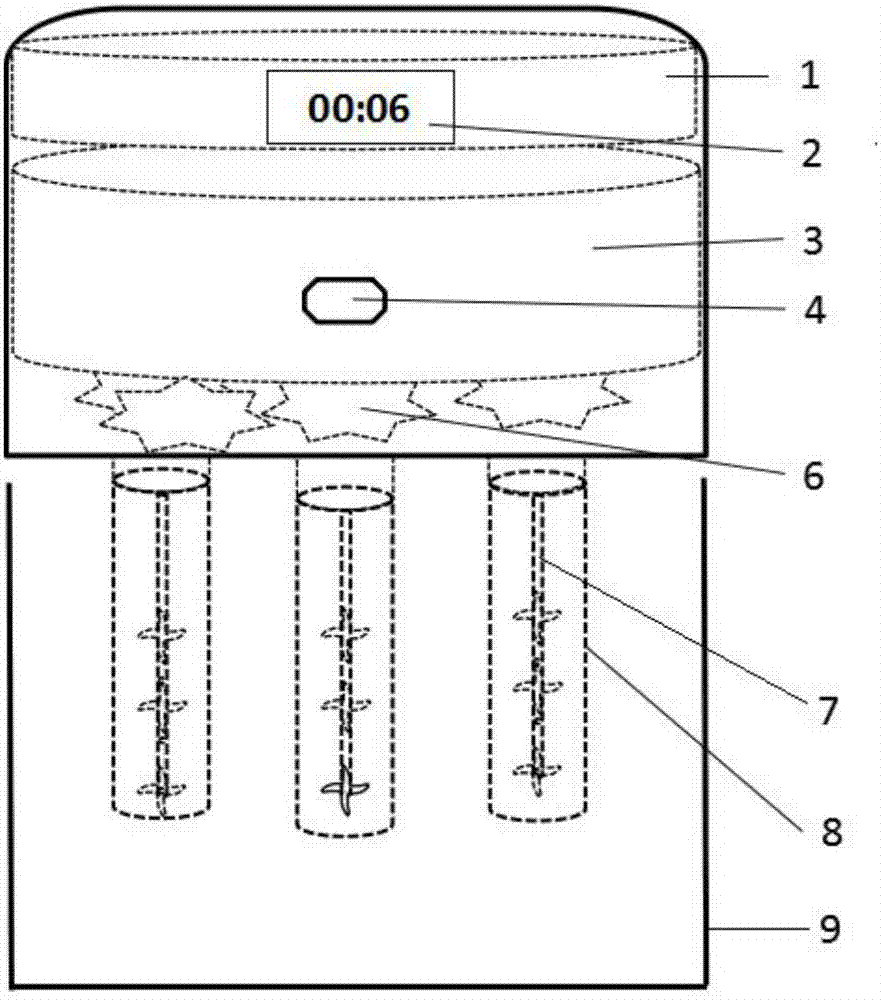

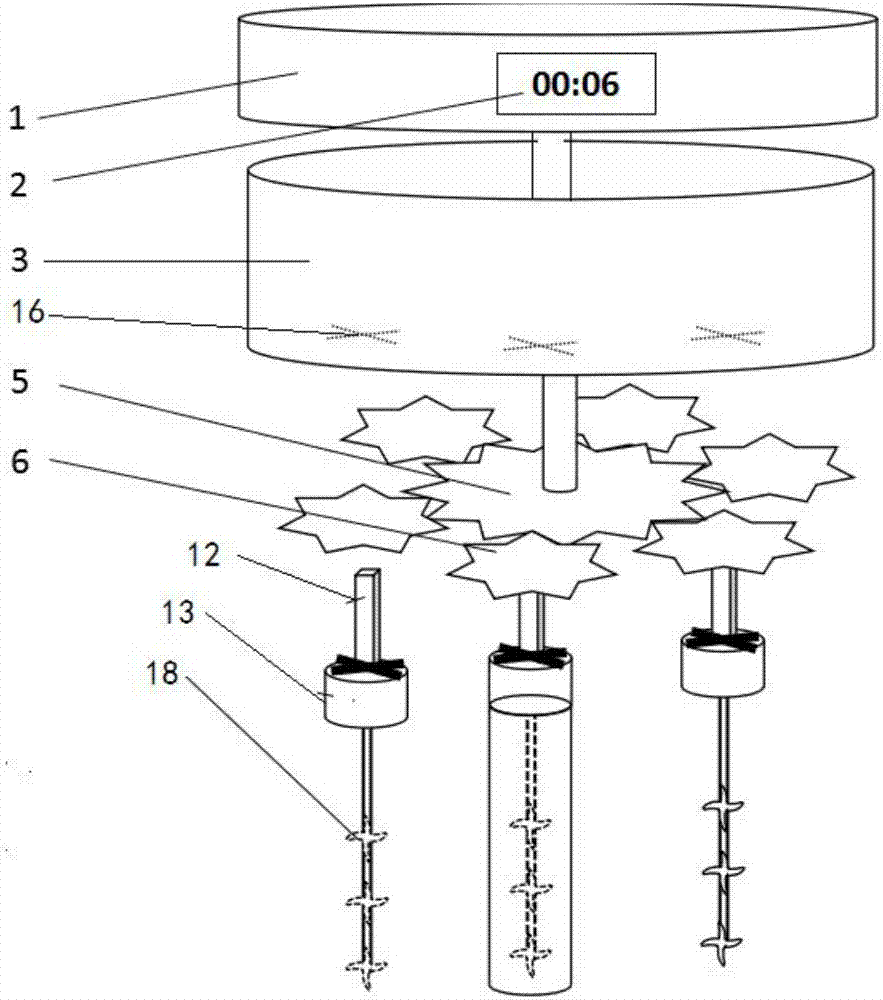

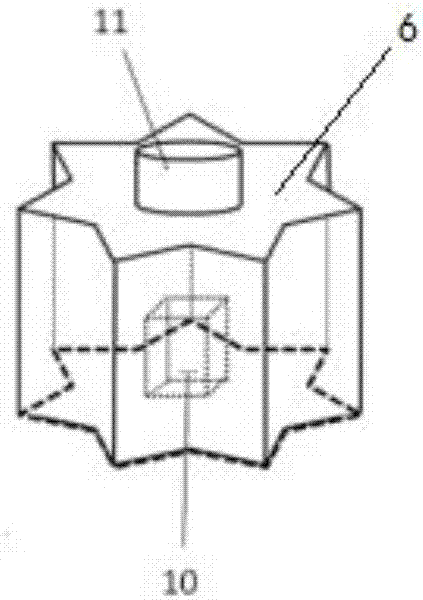

[0027] Such as Figure 1 to Figure 7 As shown, the biological tissue grinder of the present invention includes an airtight housing 17, a power unit, a transmission unit, and an execution unit arranged in the airtight housing 17, the power unit includes a motor 3, and the motor 3 adopts a micro motor 3, While ensuring the power of the grinding rod 7, the weight of the entire grinder is reduced; the transmission unit includes the main transmission gear 5, the main transmission gear 5 is connected to the motor 3, meshes with the main transmission gear 5 and is arranged symmetrically around the main transmission gear 5 At least two driven gears 6, specifically six driven gears 6; the execution unit includes a sample tube, a grinding rod 7 for grinding biological tissue in the sample tube, and the sample tube is detachably connected to the airtight housing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com