Cooling device of 3D printer

A technology of 3D printers and cooling devices, which is applied in coating devices, additive processing, etc., can solve problems such as uneven material extrusion in the air supply range, ripples on the surface of printed models, and adverse effects on printing effects, so as to avoid insufficiency in cooling Uniformity, the same cooling degree, and the effect of improving the heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

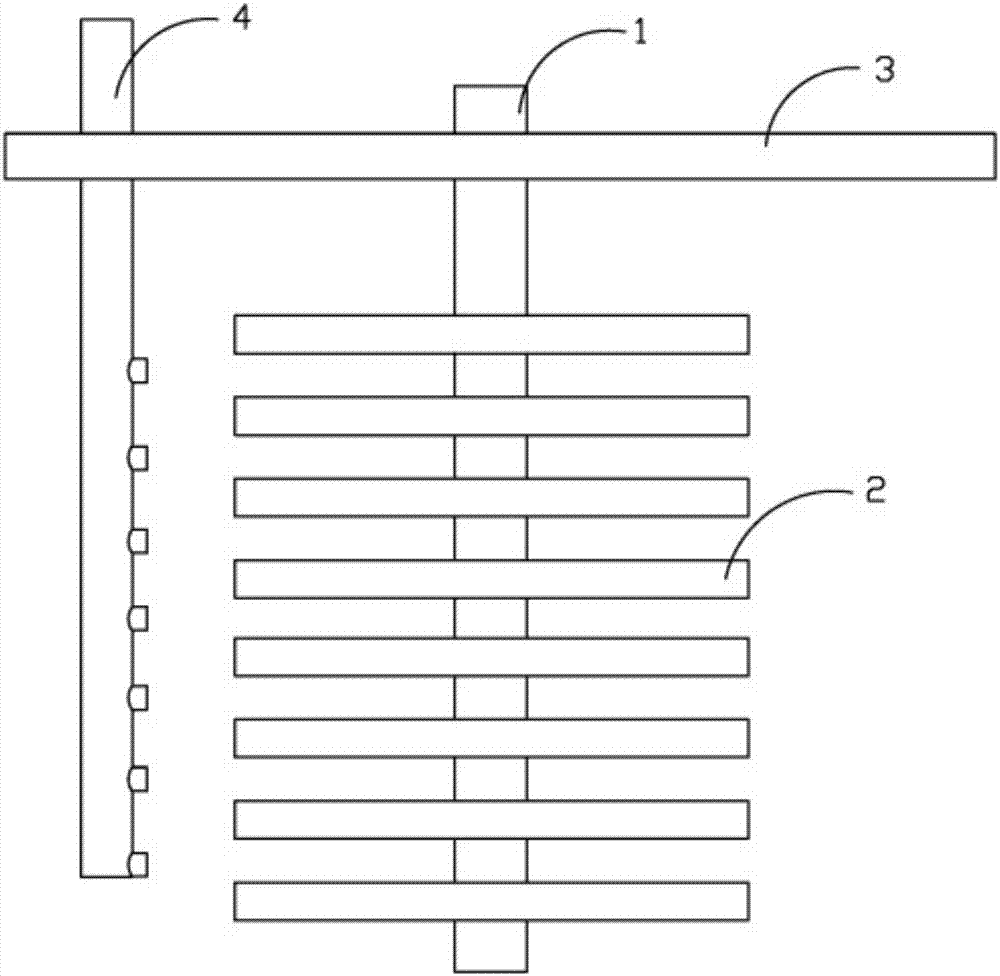

[0016] like Figure 1 to Figure 2 As shown, the cooling device of the 3D printer provided by the present invention includes a plurality of cooling fins 2 evenly arranged on the outer wall of the nozzle 1 of the 3D printer, a mounting plate 3 arranged above the cooling fins 2 and an air pipe 4 capable of blowing air to the cooling fins 2 The shape of the heat sink 2 can be various, such as triangle, polygon, circle, ellipse, etc., in the present embodiment, the heat sink 2 is circular; The inlet end of 4 is connected with the air pump, the air pipe 4 is provided with several outlets, and the direction of the outlet is opposite to the heat sink 2;

[0017] In practical application, since the heat sink 2, the mounting plate 3 and the air pipe 4 of the cooling device of the present invention are arranged around the spray head of the 3D printer, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com