Garlic clove extrusion type shelling and crushing device

A shell-crushing and extrusion-type technology, applied in the field of garlic processing equipment, can solve the problems that garlic cloves cannot be completely squeezed and peeled, the extrusion plate cannot be made very long, and cannot be adjusted flexibly, so as to achieve convenient crushing and cutting. technology, improve the skin breakage rate, and optimize the effect of space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

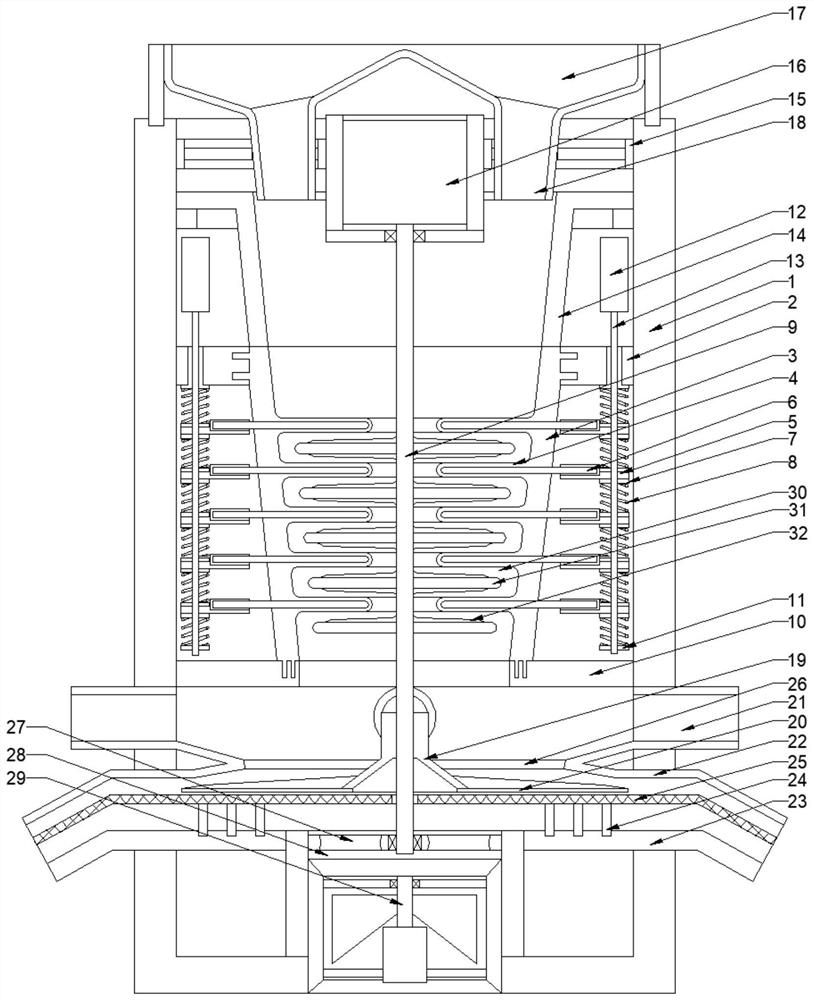

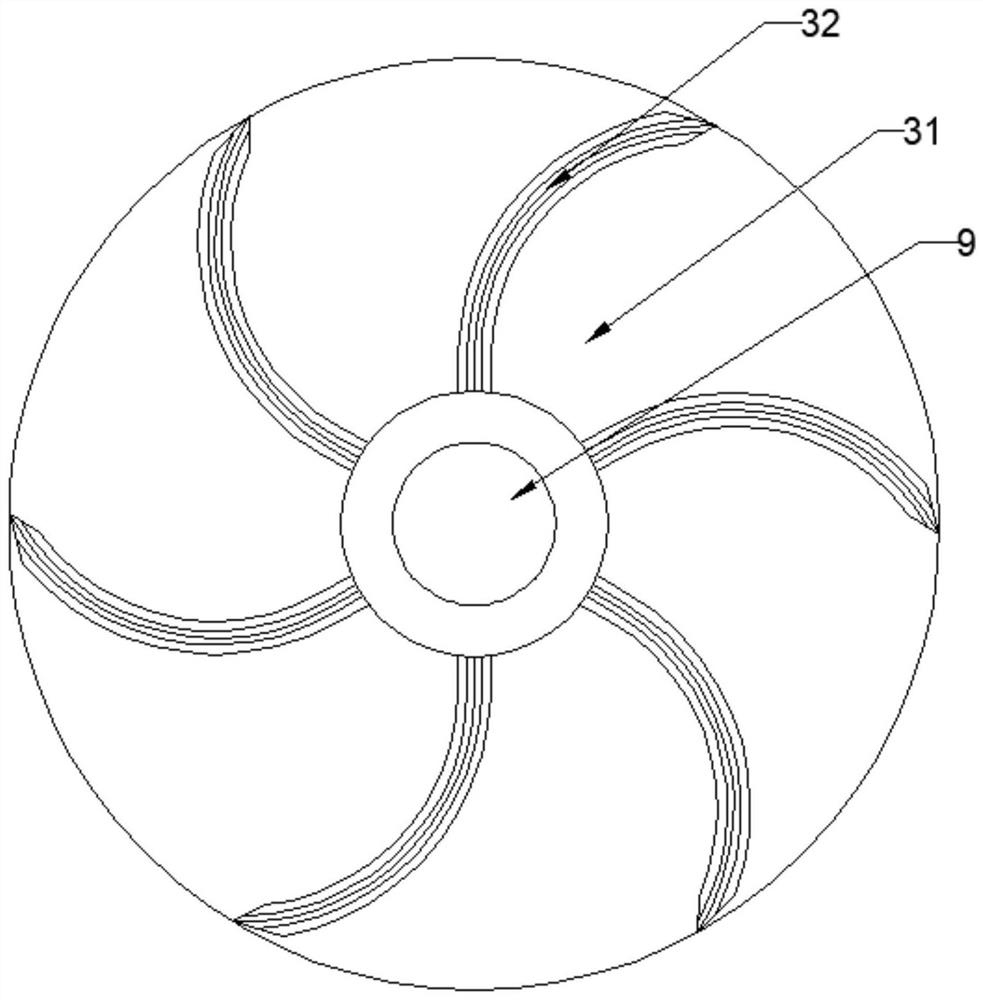

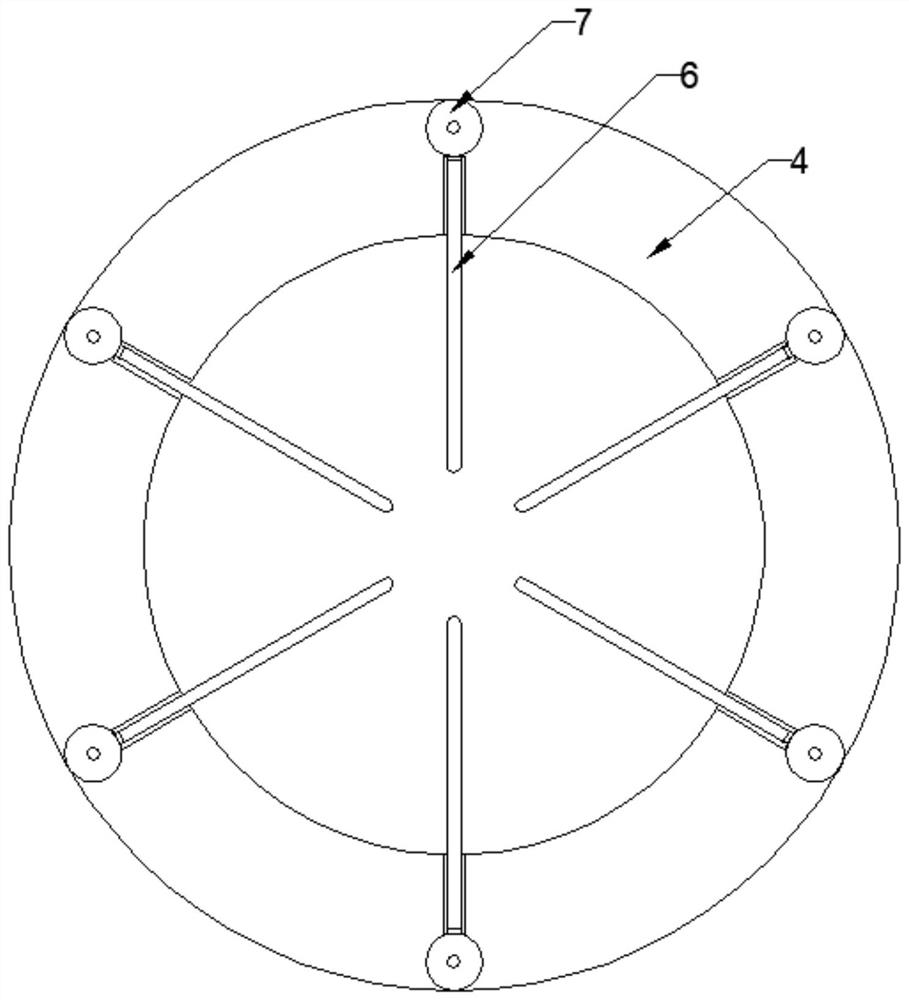

[0023] see Figure 1-3 Description of this embodiment, a garlic extrusion shelling and crushing device, which includes a support frame 1, a feeding mechanism, an extrusion mechanism, a garlic pushing mechanism, a discharge mechanism and an exhaust mechanism, and the extrusion mechanism is set on Supporting the middle part of the outer frame 1, the extruding mechanism includes a material processing bucket 3 fixed on the inner wall of the supporting outer frame 1, the material processing bucket 3 is a tapered tubular structure, and the inner wall of the material processing bucket 3 is arranged in a linear array There are several extrusion rings 4, and the middle part of the extrusion rings 4 is a discharge port, and an extrusion gap 30 is arranged between adjacent extrusion rings ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com