Alkaline cleaner of aseptic processing equipment for dairy beverages and preparation method of alkaline cleaner

A processing equipment and cleaning agent technology, applied in the direction of surface active detergent composition, detergent composition, detergent compounding agent, etc., can solve the problems of unable to meet the concentration requirements, reduce the difficulty of surfactant, add surfactant, etc. , to achieve the effect of improving anti-fouling redeposition performance, enhancing decontamination performance and anti-fouling redeposition performance, and improving comprehensive decontamination performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

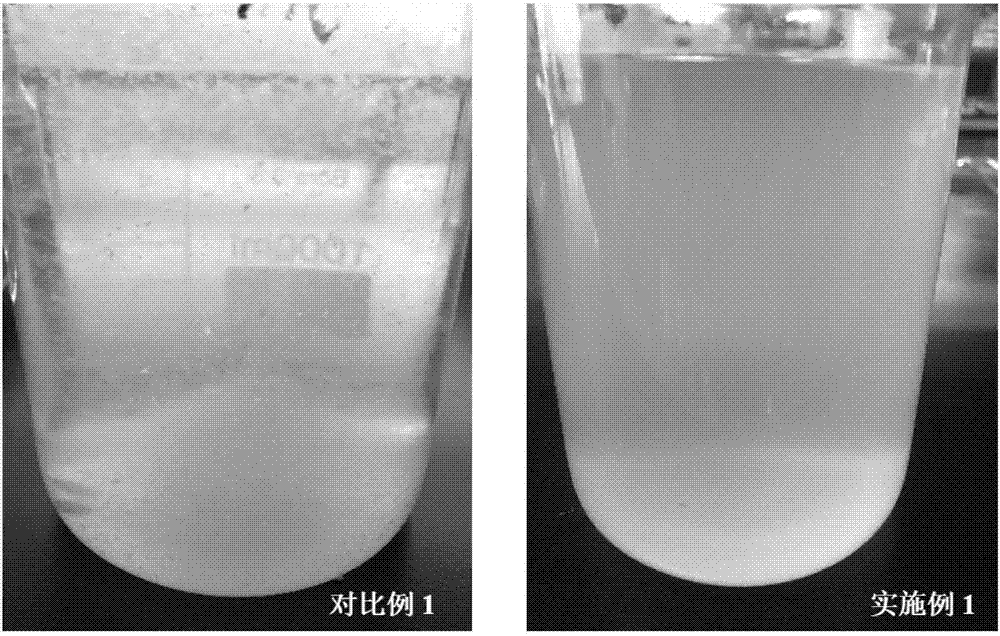

Image

Examples

Embodiment 1

[0059] The cleaning agent product preparation method of embodiment 1 is as follows: Alkyl glycoside surfactant AG6202 15kg and 5kg water are mixed and stirred evenly; Then add alkyl alcohol ether Berol 260 5kg stirring and dissolving therein; Then add chelating agent HEDP wherein -4Na 10kg, dispersant PASP 5kg, stirring and dissolving evenly; then adding liquid caustic soda (NaOH concentration is 50wt%) 960kg wherein, stirring evenly, obtain the product of embodiment 1.

Embodiment 2

[0061] The cleaning agent product preparation method of embodiment 2 is as follows: Alkyl glycoside surfactant AG6202 15kg and 5kg water are mixed and stirred evenly; Then add alkyl alcohol ether Berol 840 5kg stirring and dissolving thereinto; Then add chelating agent HEDP wherein -4Na 10kg, dispersant PASP 5kg, stirring and dissolving evenly; then adding liquid caustic soda (NaOH concentration is 50wt%) 960kg wherein, stirring evenly, obtains the product of embodiment 2.

Embodiment 3

[0063] The cleaning agent product preparation method of embodiment 3 is as follows: dissolve 15kg of alkyl glycoside surfactant SL4 and mix and stir with 5kg of water; Then add alkyl alcohol ether Berol 260 5kg to it and stir to dissolve; Then add chelate Mixture HEDP-4Na 10kg, dispersant PASP 5kg, stir and dissolve evenly; then add liquid caustic soda (NaOH concentration is 50wt%) 960kg therein, stir evenly, obtain the product of embodiment 3.

[0064] 6. Product foam performance

[0065] The foam performance (Ross-Miles method) of the products of Examples 1 to 3 was measured by a Roche foam meter, and the experimental results are shown in Table 5.

[0066] Table 5 product foam performance comparison

[0067]

[0068] 7. Decontamination performance of the product

[0069] The decontamination performance of the cleaning agent product was tested. The detergency was measured according to the method of "Alkaline Cleaner for Food Tools and Industrial Equipment" (QBT4314-2012)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com