Combined pest capture machine

A compound pest technology, which is applied to the device for capturing or killing insects, application, animal husbandry, etc., can solve the problems of easy accidental injury to natural enemies, low utilization rate, high cost, etc., to avoid accidental injury of natural enemies, adequate pest killing, The effect of attracting insects with high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

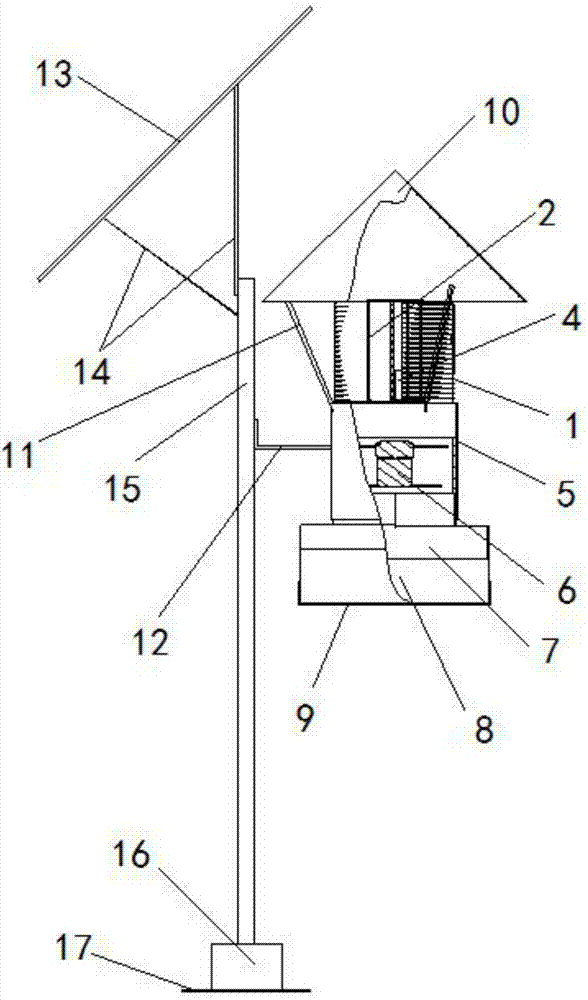

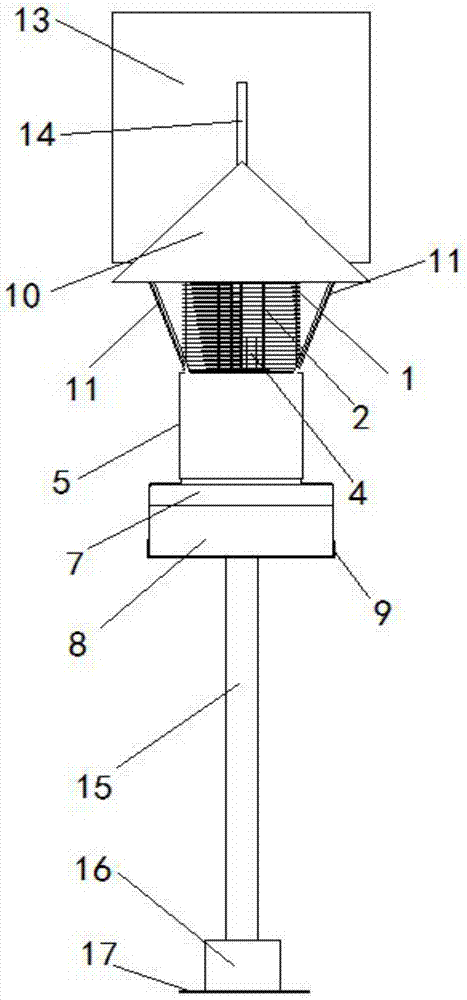

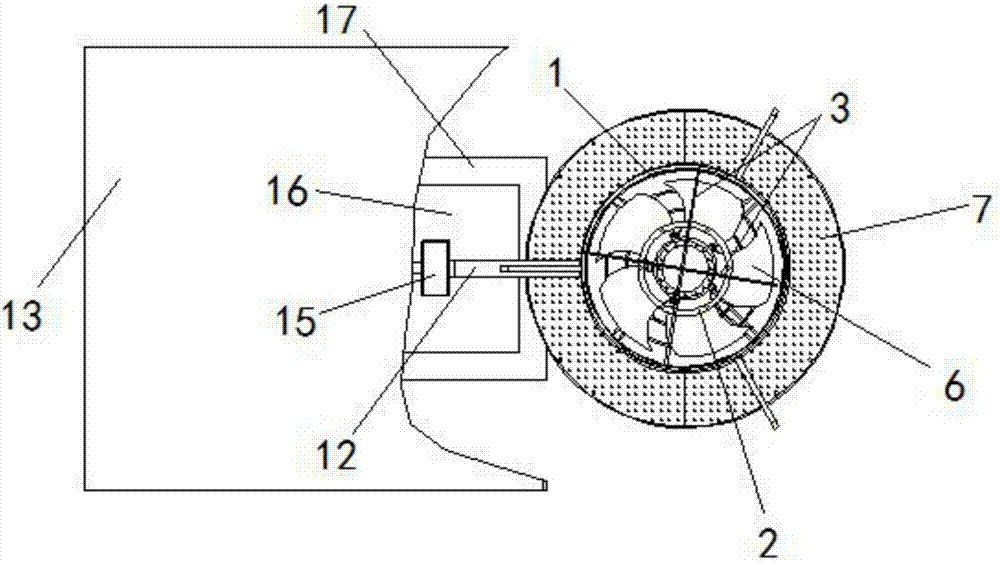

[0031] This embodiment provides a compound pest capture machine, including a power supply system, an automatic control system and a pest catching and killing system, such as figure 1As shown, the pest killing system includes a primary killing mechanism and a secondary killing mechanism that are fixedly connected up and down. The primary killing mechanism includes a high-voltage power grid, and the high-voltage power grid is surrounded by a cylindrical grid enclosure 1. The light trapping device 2, the color plate trapping device and the attractant trapping device 4, the secondary killing mechanism includes a cylindrical casing 5 and a negative pressure fan 6, and the negative pressure fan 6 is installed inside the cylindrical shell 5, The bottom end of the cylindrical grid enclosure 1 is docked with the top end of the cylindrical shell 5, and the axis of the cylindrical grid enclosure 1 coincides with the axis of the cylindrical shell 5, and the bottom of the cylindrical shell ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com