Making method of straw mushroom flavored fish sauce

A production method and a technology for straw mushrooms are applied in the directions of food ingredients as odor improvers, food ingredients as taste improvers, and functions of food ingredients, etc., and can solve the problem of long production cycle of fish sauce, heavy fishy smell, less nutrition and flavor, etc. problems, to achieve the effect of being conducive to industrial production, long-lasting flavor and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

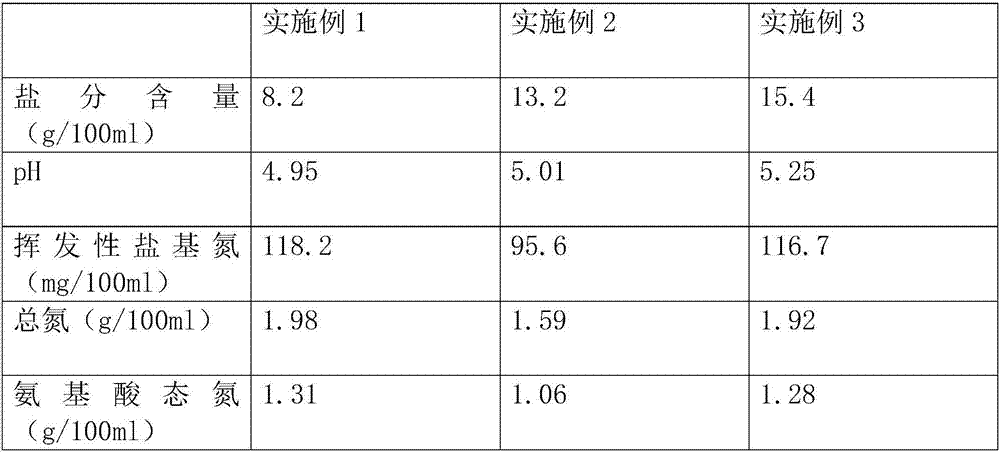

Embodiment 1

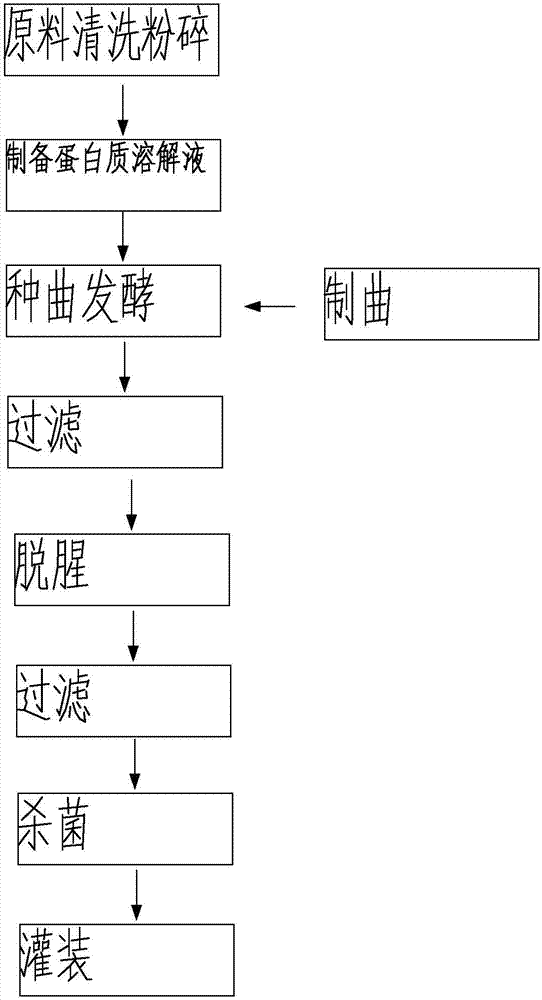

[0041] A kind of preparation method of straw mushroom flavor fish sauce, reference figure 1 , including the following steps:

[0042] 1) Firstly mix 6.8kg of clams, 4.1kg of fresh straw mushroom grains, 8.2kg of wheat, and 11kg of water, steam the ingredients in a steamer for 1.5h under pressure at 0.2MPa to obtain clinker; cool the clinker to room temperature quickly , insert 140g of Aspergillus oryzae strains, mix well, send it into the koji pond, maintain the temperature at 30°C, ventilate intermittently after 6 hours in the koji pond, continue to ventilate after 12 hours in the koji pond, and make koji after 48 hours, during which every half hour Turn over once an hour.

[0043] 2) After cleaning 50kg of sardines, use a chopping machine at 1600r / min, chop and mix for 3 minutes at a temperature of 5°C to form minced meat, and observe that the minced meat is sticky.

[0044] 3) Add 50 kg of clear water to the minced meat described in step 2, stir evenly, add 0.1 kg of comp...

Embodiment 2

[0052] A method for preparing straw mushroom flavored fish sauce, comprising the following steps:

[0053] 1) Firstly mix 1.7kg of clams, 1.7kg of fresh straw mushroom grains, 7.7kg of wheat, and 6kg of water, steam the ingredients in a steamer for 1 hour at a pressure of 0.3MPa to obtain clinker; quickly cool the clinker to room temperature , add 170g of Aspergillus oryzae strain, mix well, send it into the koji pond, maintain the temperature at 35°C, ventilate intermittently after 6 hours in the koji pond, continue to ventilate after 12 hours in the koji pond, and make koji after 48 hours, during which every half hour Turn over once an hour.

[0054] 2) After cleaning 50kg of leftover fish material, use a chopping machine at 1600r / min, chop and mix for 5min at 1°C to form minced meat, and observe that the minced meat is sticky.

[0055] 3) Add 75 kg of clear water to the minced meat described in step 2, stir evenly, add 0.25 kg of compound protease, compound protease is try...

Embodiment 3

[0064] A method for preparing straw mushroom flavored fish sauce, comprising the following steps:

[0065] 1) Thoroughly mix 3.6kg of scorpion scalp, 2.4kg of fresh straw mushroom grains, 7kg of wheat, and 7kg of water, steam the ingredients in a steamer for 1 hour under pressure at 0.3MPa; quickly cool to room temperature, insert 160g of Aspergillus oryzae strain, Mix well, send it into the koji pond, maintain the temperature at 32°C, ventilate intermittently after 6 hours in the koji pond, and ventilate continuously after 12 hours in the koji pond, and make koji after 48 hours, turning the koji every half an hour during this period.

[0066] 2) After cleaning 50kg of leftover fish material, use a chopping machine at 1600r / min, chop and mix for 4 minutes at 3°C to form minced meat, and chop and mix until the minced meat becomes sticky.

[0067] 3) Add 60 kg of clear water to the minced meat described in step 2, stir evenly, add 0.15 kg of compound protease, the compound pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com