Sponge for mattresses and preparation method thereof

A sponge and mattress technology, applied in the field of mattress sponges, can solve the problems of metal springs with noise, unsatisfactory support, easy to break the surface, etc., to achieve the effect of reducing metal products, improving immunity, and good health effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

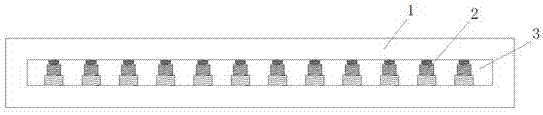

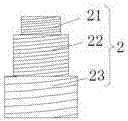

[0024] refer to Figure 1-2 , a mattress sponge proposed by the present invention comprises a sponge body 1, a placement groove 3 is provided in the sponge body 1, and a plurality of spring mechanisms 2 arranged in a rectangular shape are arranged in the placement groove 3, and the spring The mechanism 2 includes a first plastic spring 21, a second plastic spring 22 and a third plastic spring 23 arranged in sequence from top to bottom, and the elastic forces of the first plastic spring 21, the second plastic spring 22 and the third plastic spring 23 increase sequentially. Large, the sponge body 1 includes the following raw materials in parts by weight: 100 parts of polyether polyol composite material, 50 parts of polyester, 30 parts of toluene diisocyanate, 9 parts of tourmaline powder, 20 parts of bamboo fiber powder, 3 parts of graphene , 5 parts of carbon black, 1 part of silicone resin, 20 parts of Chinese medicine composition.

[0025] The polyether polyol composite mate...

Embodiment 2

[0033] refer to Figure 1-2 , a mattress sponge proposed by the present invention comprises a sponge body 1, a placement groove 3 is provided in the sponge body 1, and a plurality of spring mechanisms 2 arranged in a rectangular shape are arranged in the placement groove 3, and the spring The mechanism 2 includes a first plastic spring 21, a second plastic spring 22 and a third plastic spring 23 arranged in sequence from top to bottom, and the elastic forces of the first plastic spring 21, the second plastic spring 22 and the third plastic spring 23 increase sequentially. Large, the sponge body 1 includes the following raw materials in parts by weight: 105 parts of polyether polyol composite material, 55 parts of polyester, 35 parts of toluene diisocyanate, 12 parts of tourmaline powder, 25 parts of bamboo fiber powder, and 5 parts of graphene , 7 parts of carbon black, 3 parts of silicone resin, 25 parts of Chinese medicine composition.

[0034] The polyether polyol composit...

Embodiment 3

[0042] refer to Figure 1-2 , a mattress sponge proposed by the present invention comprises a sponge body 1, a placement groove 3 is provided in the sponge body 1, and a plurality of spring mechanisms 2 arranged in a rectangular shape are arranged in the placement groove 3, and the spring The mechanism 2 includes a first plastic spring 21, a second plastic spring 22 and a third plastic spring 23 arranged in sequence from top to bottom, and the elastic forces of the first plastic spring 21, the second plastic spring 22 and the third plastic spring 23 increase sequentially. Large, the sponge body 1 includes the following raw materials in parts by weight: 110 parts of polyether polyol composite material, 60 parts of polyester, 40 parts of toluene diisocyanate, 13.5 parts of tourmaline powder, 30 parts of bamboo fiber powder, and 6 parts of graphene , 7.5 parts of carbon black, 5.5 parts of silicone resin, and 30 parts of traditional Chinese medicine composition.

[0043] The pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com