A closed system of ceramic filter elements

A ceramic filter element and closed system technology, which is applied in fixed filter element filters, filtration separation, gravity filters, etc., can solve the problems of the influence of liquid filtration rate, small diameter of inlet and outlet water, etc., to increase practical value, facilitate processing and molding, Easy to uninstall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

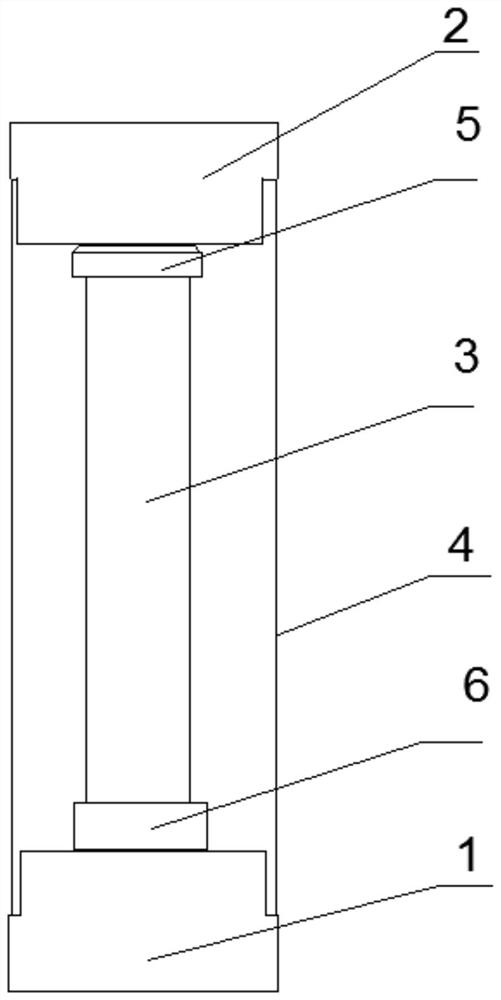

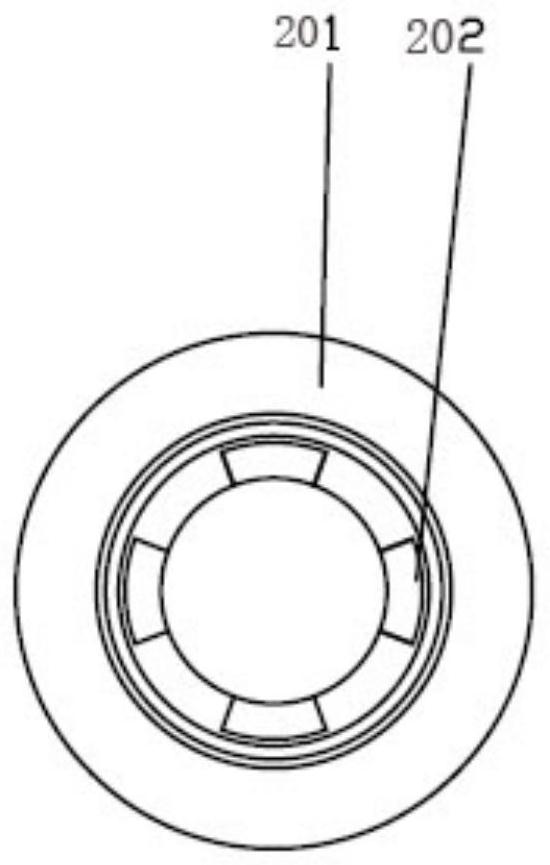

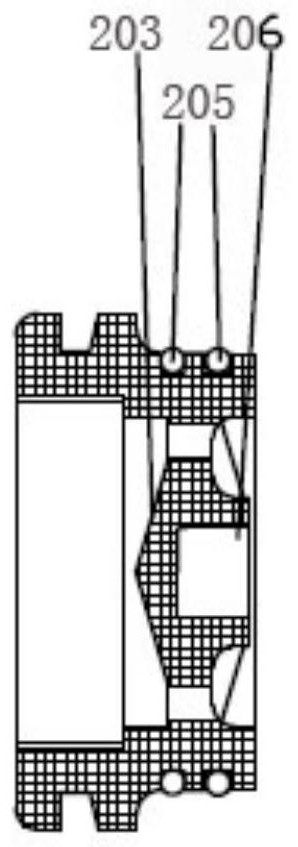

[0033] as attached Figure 1-Figure 11 As shown, a closed system of a ceramic filter element includes a water outlet head 1, a water inlet head 2, a water inlet head fixing plate 5, an outlet water head fixing plate 6, a filter element 3, and an outer wall 4. The filter element 3 is a circular column Hollow body structure, the water inlet head 2 is located on the top of the filter element 3, fixed by the water inlet head fixing plate 5; the water outlet head 1 is located at the bottom of the filter element 3, fixed by the water outlet head fixing plate 6, and the outer wall 4 is a circular cylindrical structure. Socketed on the water outlet head 1, the water inlet head 2, the water outlet head fixed plate 6, the water inlet head fixed plate 5, and the outside of the filter element 3.

[0034] One side of the water outlet head 1 is provided with a water outlet head fixed disk connection port 102 for connecting the water outlet head fixed disk. The water outlet head fixed disk c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com