Wood strip production device for toothpick production

A production device and a technology of wooden belts, which are applied in the manufacture of wooden sticks, wood processing equipment, and manufacturing tools, etc., can solve the problems of large cutting volume, complicated equipment, and large device complexity, so as to prevent waste of cutting volume and prevent further processing The effect of excessive dosage and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

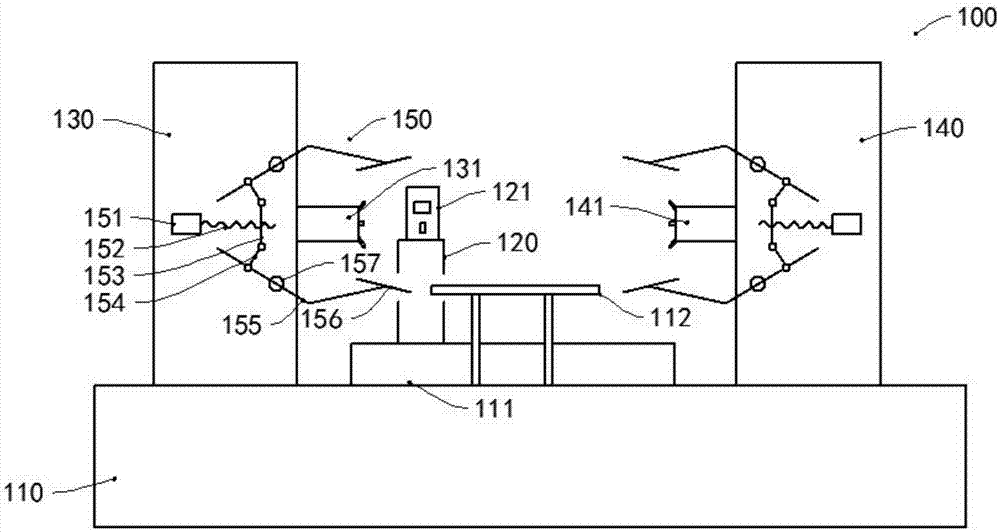

[0021] Embodiment: be used for the wooden band production device of toothpick production, constitute as Figure 1 to Figure 5 As shown, it includes a full circle device 100 and a tape cutting device 200 arranged in sequence;

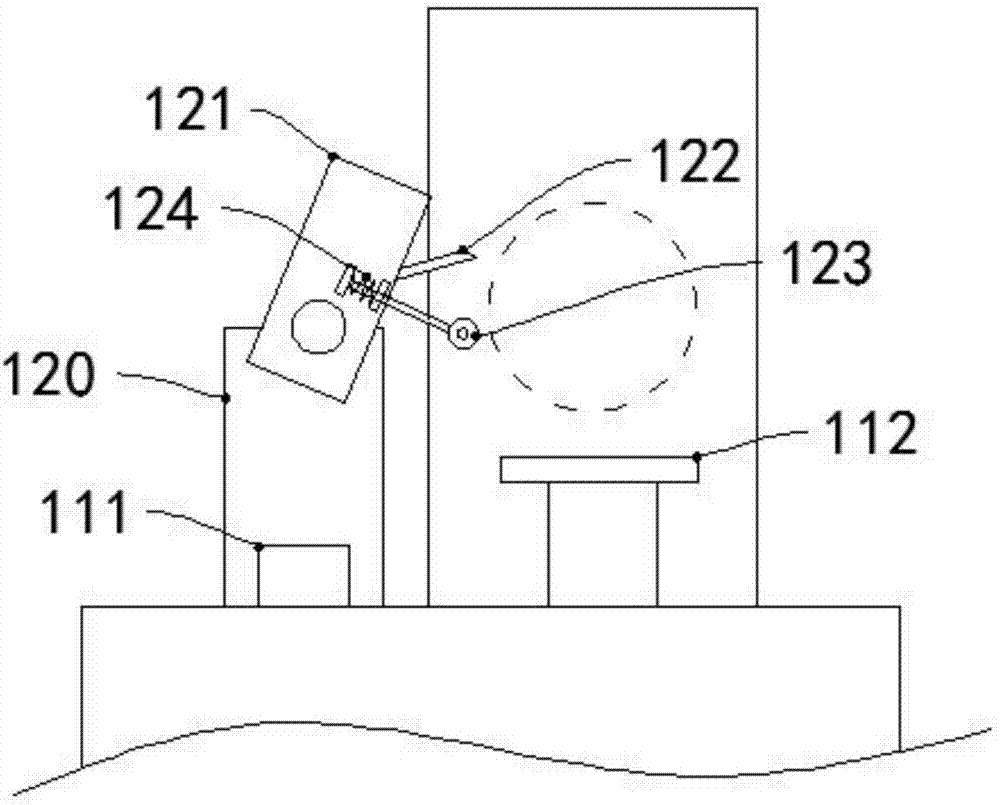

[0022] Described full circle device 100 comprises base 110, and base 110 is provided with slide rail 111, and slide rail 111 is provided with knife seat 120, as image 3 As shown, a cutter head 121 is provided on the cutter head 120, a cutter 122 is arranged on the cutter head 121, a roller 123 is arranged below the cutter 122, and a spring 124 is provided at the joint between the roller 123 and the cutter head 121; the slide rail 111 One side of the fixed seat 130 is provided with a fixed seat 130, the fixed seat 130 is provided with a main shaft 131, the other side of the slide rail 111 is provided with a movable seat 140, and the movable seat 140 is provided with a driven shaft 141; the fixed seat 130 and the movable Centering clamping devices 150 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com