Preparation method of glass shell, glass shell and electronic device

A glass shell and glass substrate technology, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve problems such as waste, achieve the effects of increased density, wide application range, and good decorative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] An embodiment of the present invention provides a method for preparing a glass case, comprising the following steps:

[0023] crushing the glass matrix and mixing it with a binder to obtain a mixture;

[0024] Drying the mixture to obtain glass shell powder;

[0025] Fill the glass shell powder into the preset mold, and press to obtain the pre-finished glass shell;

[0026] A sintering process is performed on the glass envelope preform.

[0027] In the preparation method of the glass shell in this embodiment, the pulverized glass matrix powder is mixed with a binder, and then dried to remove the moisture in the mixture and prevent bubbles and pinholes inside the glass shell, which is beneficial to improve the glass shell. density. Filling the glass shell powder into a preset mold and pressing to obtain a glass shell preform, and then sintering the glass shell preform to obtain a glass shell. The preparation method does not need to cut the whole piece of glass, which...

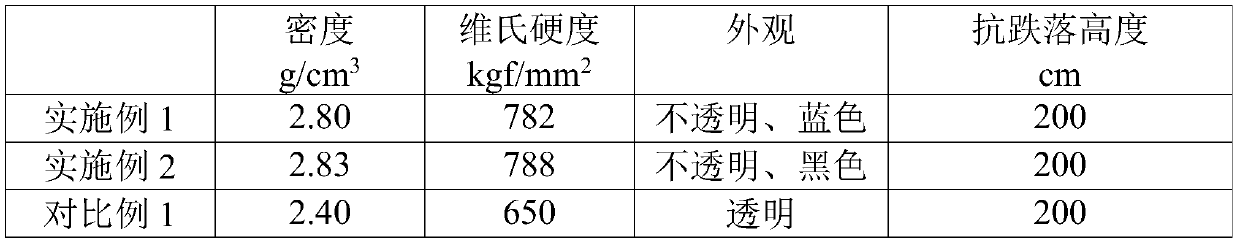

Embodiment 1

[0045] The glass-ceramic substrate is taken and pulverized by a ball mill to form a slurry with a particle size of 1 μm-10 μm. In the slurry, add 3% polyvinyl alcohol accounting for the quality of the glass-ceramic substrate as a binding agent, and 4% cobalt blue material accounting for the quality of the glass-ceramic substrate as a colorant, so that the slurry, adhesive The binder and the colorant are thoroughly mixed to obtain a mixture.

[0046] The mixture is dried by a centrifugal dryer, the rotational speed of the centrifugal nozzle of the dryer is 250r / s, and the temperature of the drying chamber is 280°C. After drying, a glass shell powder is obtained.

[0047] Fill the glass shell powder into the preset mold, hold the pressure for 10s under the pressure of 25MPa, and press to obtain the pre-finished glass shell.

[0048] The glass shell preform is moved into a sintering furnace for sintering. After debinding at 400°C for 1 hour, sintering at 600°C for 30 minutes, ...

Embodiment 2

[0051] The glass-ceramic substrate is taken and pulverized by a ball mill to form a slurry with a particle size of 1 μm-10 μm. In this slurry, add the polyvinyl alcohol that accounts for 5% of the quality of glass-ceramics matrix as binder, and account for the cobalt black material of 4% of the quality of glass-ceramics matrix as pigment, make slurry, bonding The agent and the colorant are mixed thoroughly to obtain a mixture.

[0052] The mixture was dried by a centrifugal dryer, the rotational speed of the centrifugal nozzle of the dryer was 220r / s, and the temperature of the drying chamber was 265°C. After drying, a glass shell powder is obtained.

[0053] Fill the glass shell powder into the preset mold, hold the pressure for 10s under the pressure of 25MPa, and press to obtain the pre-finished glass shell.

[0054] The glass shell preform is moved into a sintering furnace for sintering. After debinding at 400°C for 1 hour, sintering at 600°C for 30 minutes, and sinteri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com