A concrete curtain wall panel composed of honeycomb panel components and its manufacturing method

A honeycomb panel and concrete technology, applied in building components, chemical instruments and methods, walls, etc., can solve the problems of poor thermal insulation effect and durability, unenvironmental protection, lack of engineering experience, etc. Easy to transport and hoist

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

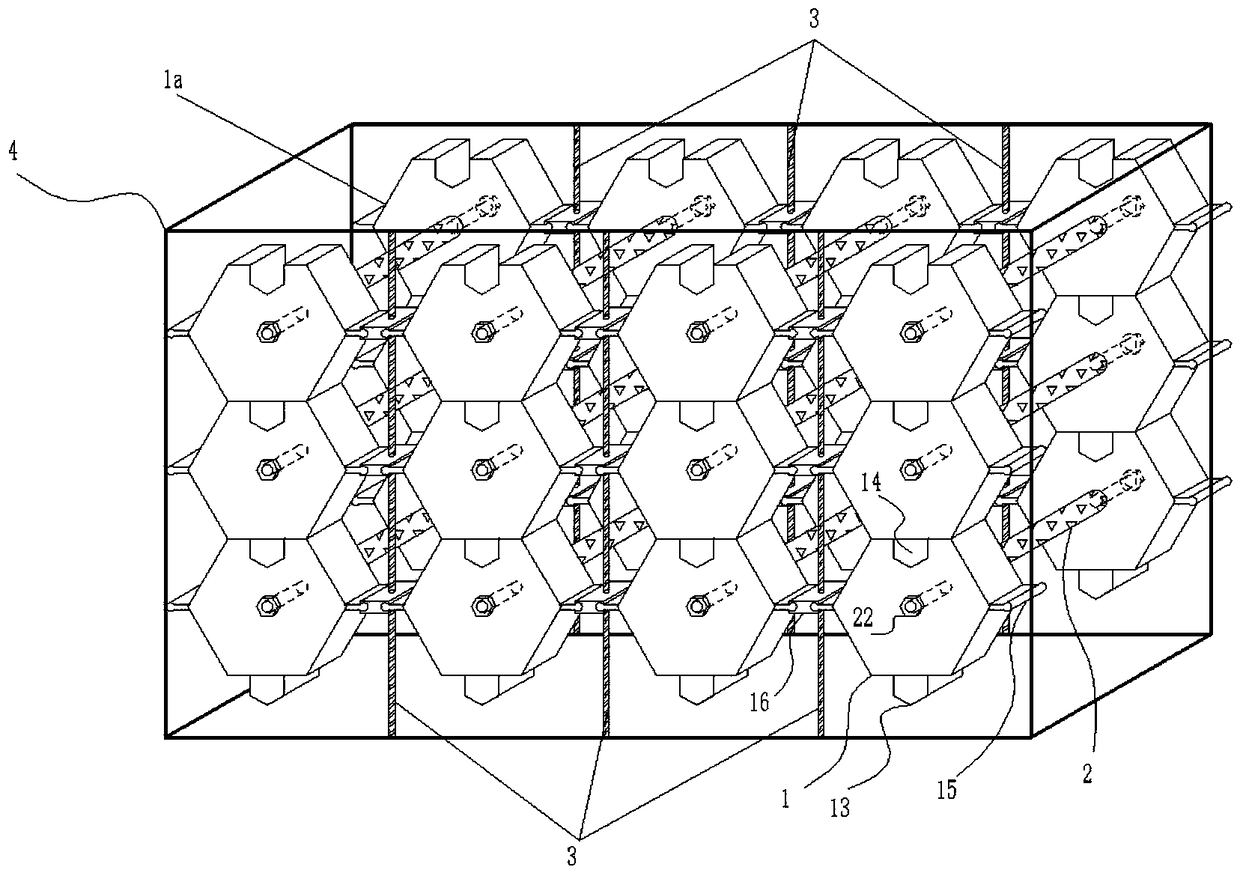

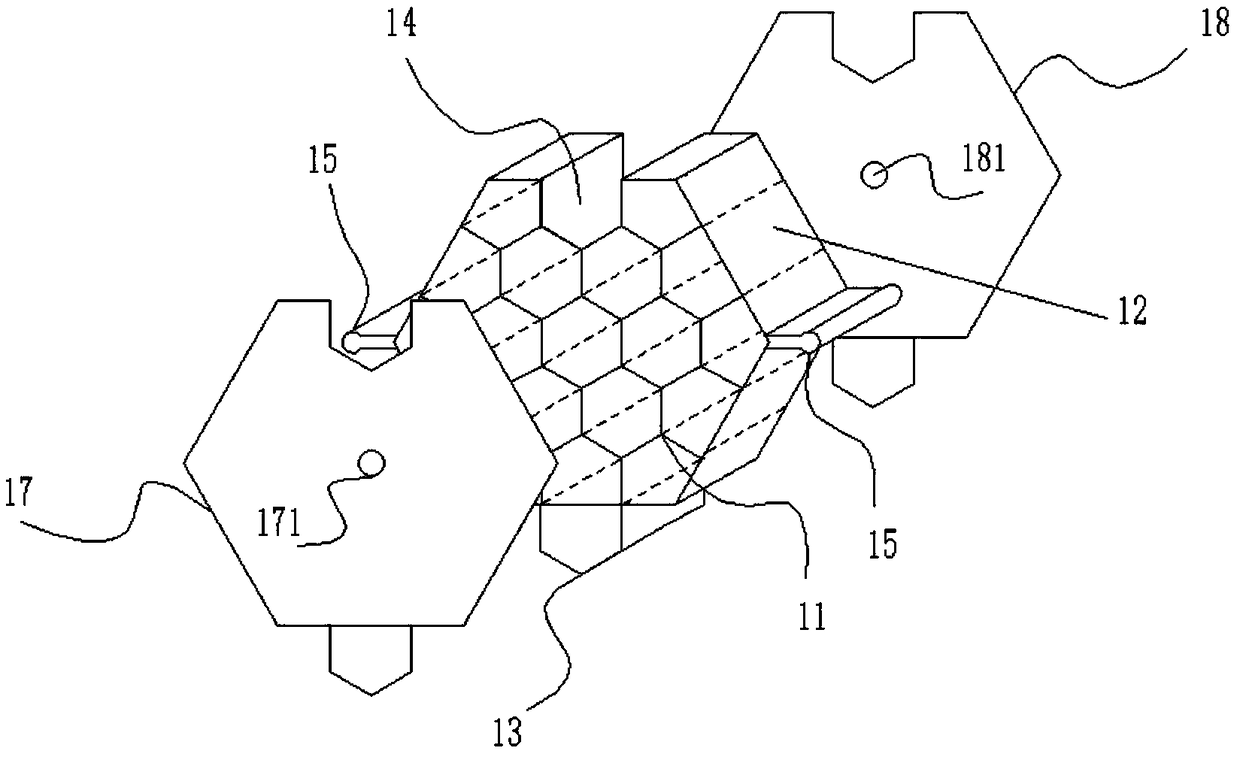

[0037] To facilitate the understanding of the embodiments of the present invention, the following combination Figure 1-11 For further explanation, the embodiments do not constitute a limitation to the embodiments of the present invention.

[0038] Such as figure 2 As shown, a concrete curtain wall panel composed of honeycomb panel components mainly includes honeycomb panel components, transverse connecting members 2, longitudinal steel bars 3, peripheral fixed frame 4, concrete layer 5, thermal insulation material layer 6, thermal insulation material layer 7 and Interface decoration layer 8, wherein the material of the honeycomb panel member 1 is preferably a fiber reinforced composite material. The fiber reinforced composite material has high specific strength, large specific modulus, designable material properties, corrosion resistance and durability. Good and the coefficient of thermal expansion is similar to that of concrete.

[0039] Such as image 3 As shown, the honeycomb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com