Lightweight vehicle rear torsion bar suspension rack

A torsion bar, light-weight technology, applied in the direction of power plant, vehicle parts, jet propulsion device, etc., can solve the problems that cannot meet the requirements of lightweight engine structure, improve the fuel consumption rate of the whole vehicle, and high manufacturing cost, and meet the requirements of light weight Quantitative requirements, reduced fuel consumption, and low manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

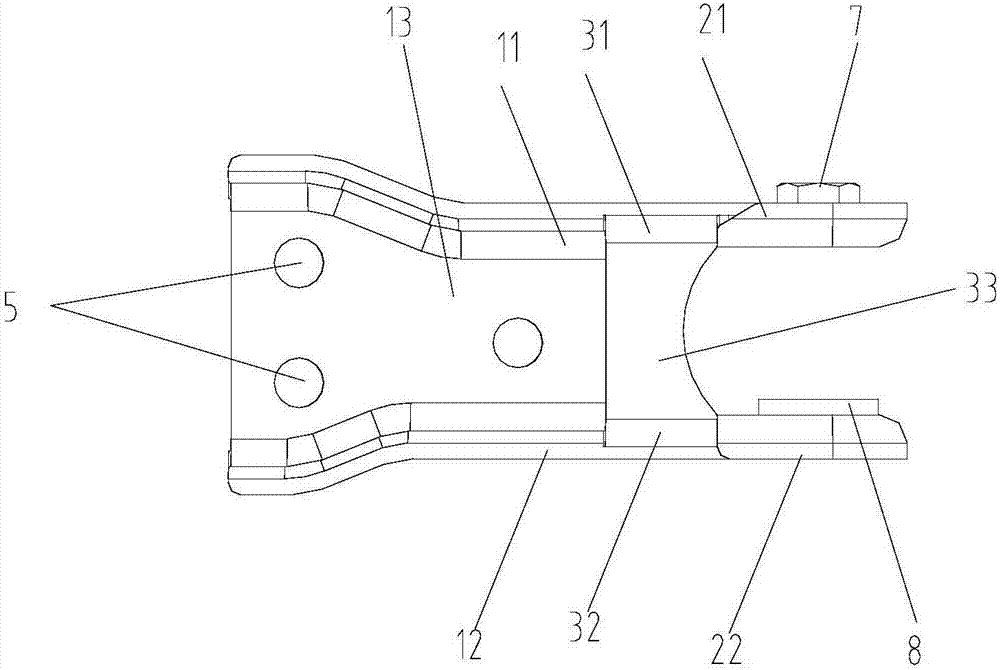

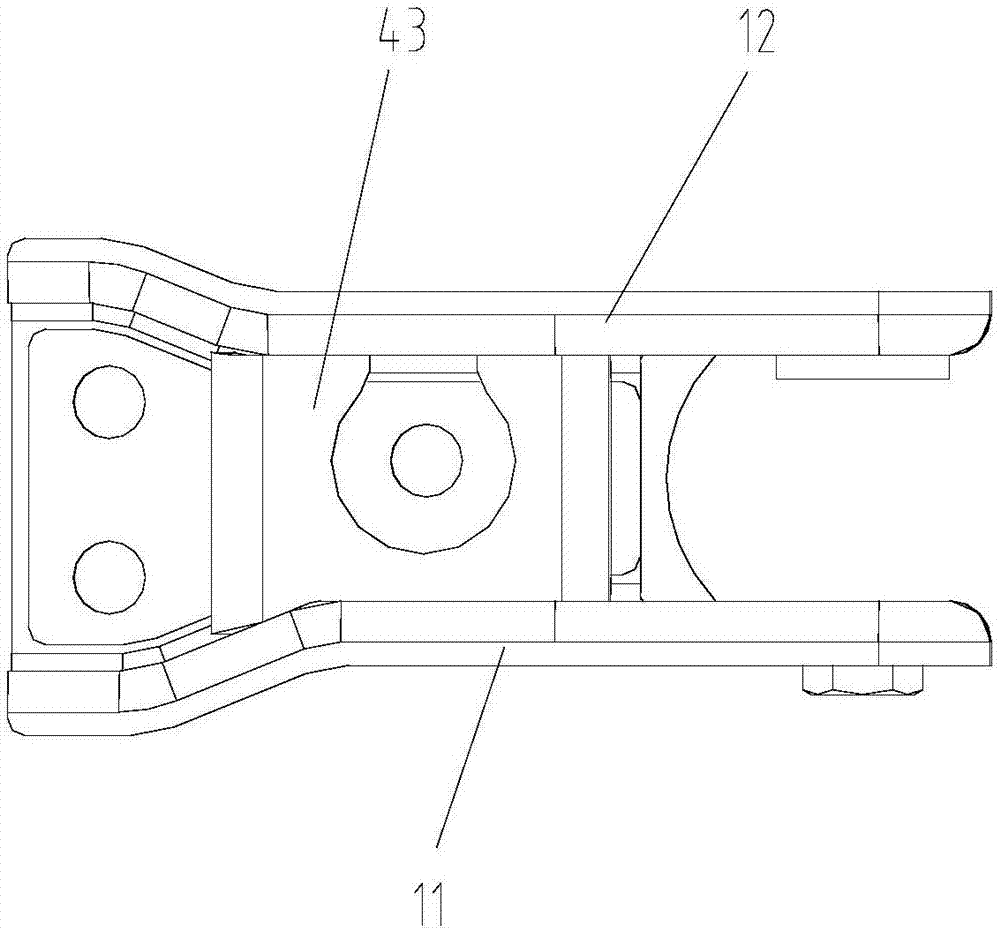

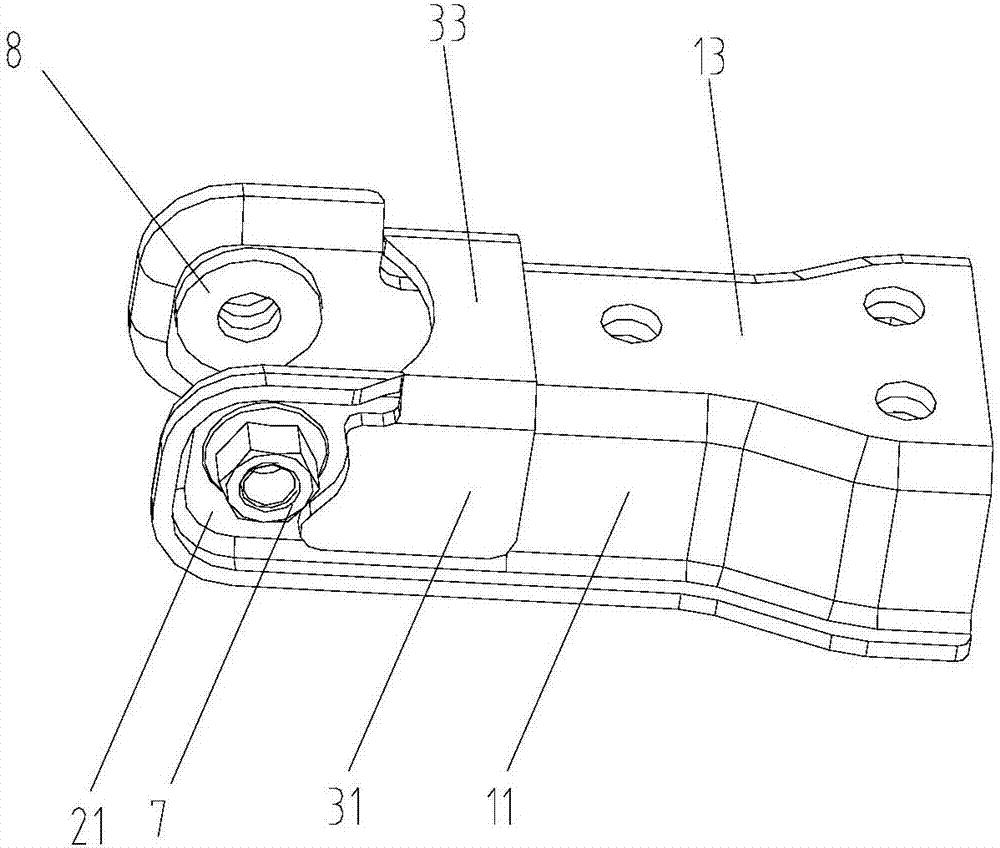

[0022] Such as Figure 1 to Figure 4 As shown: the light-weight automobile rear torsion bar suspension bracket of this embodiment includes a longitudinal plate I11 and a longitudinal plate II12 arranged symmetrically with the longitudinal plate I11, the upper edge of the longitudinal plate I11 and the upper end edge of the longitudinal plate II12 Connected by a horizontal plate 13, the vertical plate I11, the vertical plate II12 and the horizontal plate 13 are all sheet metal structures and integrally formed; the horizontal plate 13 is provided with an engine connection part for connecting with the engine; The left edge of the plate I11 and the longitudinal plate I11 extends to the left to form the ear plate I21 and the ear plate II22, and the ear plate I21 and the ear plate II22 are provided with a cushion connection part for connecting with the rear torsion bar suspension cushion assembly; top, bottom, left image 3 The direction shown shall prevail; the longitudinal plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com