Movable cloth discharging mechanism with water returning function

An active and functional technology, applied in the direction of liquid/gas/vapor removal with squeeze rollers, processing textile material carriers, and processing textile material equipment configuration, etc., to achieve optimal cost control, avoid slippery pollution and safety issues, and reduce heating effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

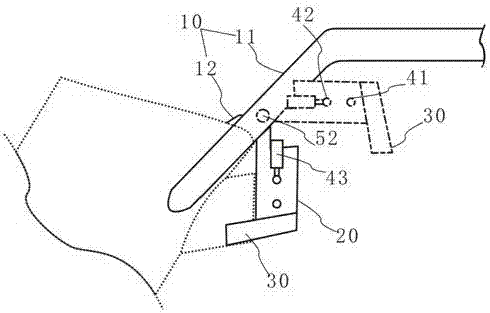

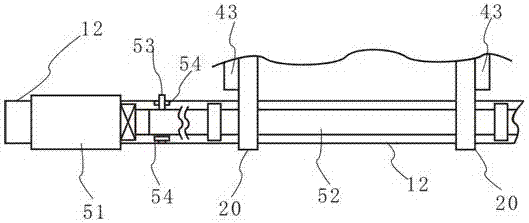

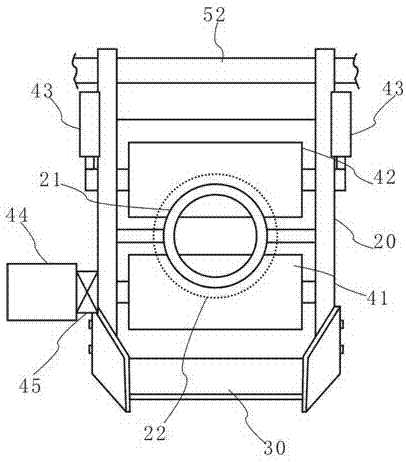

[0024] Such as Figure 1-3 As shown, the present embodiment provides a movable cloth outlet mechanism with water return function, which includes a mounting frame 10 , a cloth guide frame 20 arranged on the mounting frame 10 , a liquid squeezing assembly and a backflow tank 30 . The mounting frame 10 is fixedly mounted on the cloth outlet of the cylinder of the dyeing machine, and includes side frames 11 symmetrically arranged on both lateral sides of the cloth outlet of the cylinder body and horizontal frames 12 horizontally connected between the side frames 11 .

[0025] In this embodiment, the horizontal frame 12 is provided with a rotating motor 51 and a rotating shaft 52, the rotating shaft 52 is arranged on the horizontal frame 12 through a bearing seat and driven to rotate by the rotating motor 51, and the fabric guide frame 20 One end of one end is fixedly connected with the rotating shaft 52, and the specific connection method adopts a conventional connection structure...

Embodiment 2

[0032] Such as Figure 4-5As shown, this embodiment provides a movable cloth outlet mechanism with water return function. This embodiment is further improved on the basis of the technical solution of the first embodiment above. The side frame 11 close to the power body of this embodiment A guide groove 13 is provided, and the power body slides and fits with the guide groove 13 through the connecting seat 46, and the guide groove 13 is an arc structure concentrically arranged with the rotating shaft 52, and the guide groove 13 Both ends of the head and tail are provided with a limiting groove 14 that supports and cooperates with the connecting seat 46, and the limiter 60 is movably combined in the limiting groove 14, and one end of the connecting seat 46 is controlled by The limit groove 14 is supported by the limit member 60, so that the structural stability of the power body and the fabric guide frame 20 of this embodiment can be enhanced, and at the same time, it does not af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com