Jet flow groove cooling structure capable of improving cooling efficiency of stator leading edge nearby end wall

A technology of cooling efficiency and cooling structure, applied in the direction of stators, engine components, machines/engines, etc., can solve problems such as inability to obtain cooling protection, achieve the effects of eliminating high heat load areas, reducing separation, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

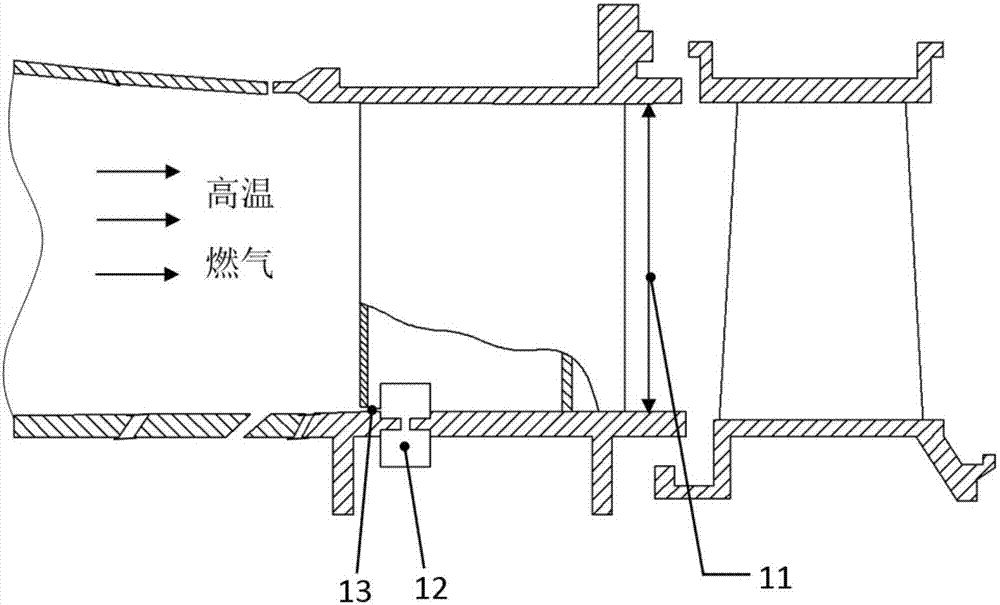

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and technical principles. Concrete structure of the present invention sees appendix Figure 3-8 , the design idea is as follows:

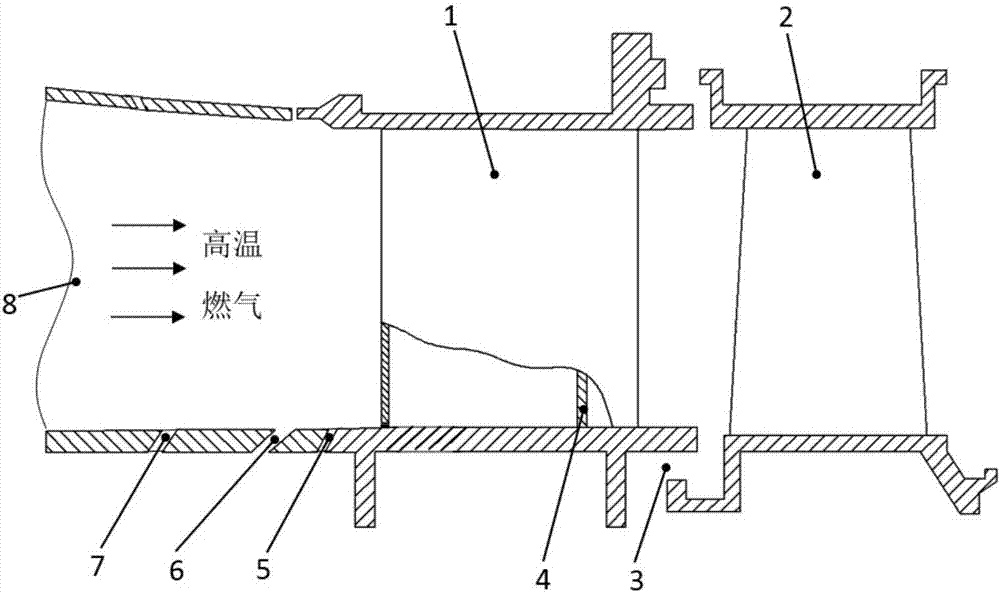

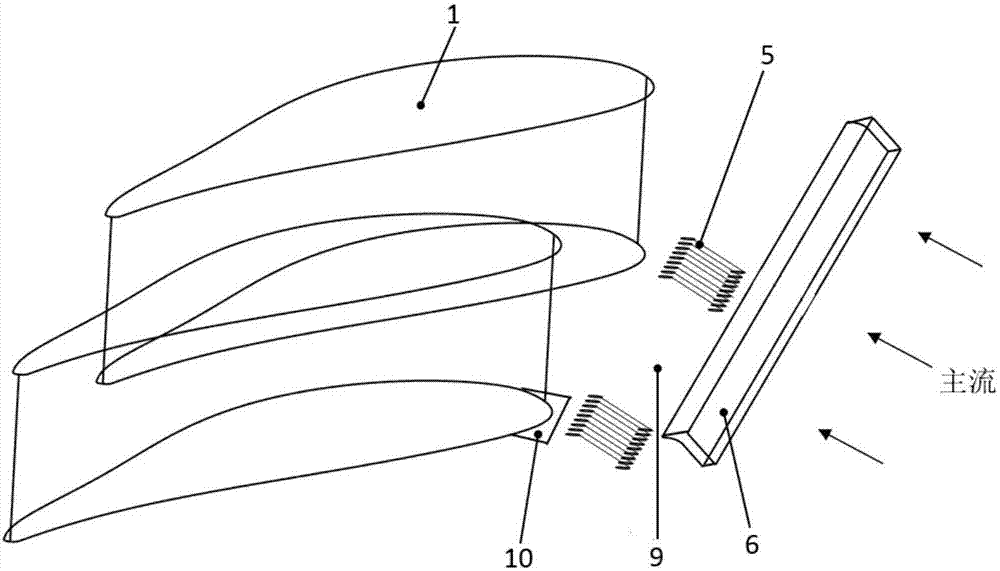

[0033] see image 3 and Figure 4 The jet groove cooling structure provided by the present invention has the cooling efficiency of the end wall near the leading edge of the vane, including the cooling jet chamber 12 and the jet groove 13 installed at the root of the gas turbine vane 1; wherein the cooling jet chamber 12 is along the The direction of the cooling flow runs through the root of the gas turbine vane 1, and the jet slot 13 runs through the rib 4 inside the vane from the combustion chamber 8 along the intake direction of the high-temperature gas and communicates with the outlet of the cooling jet chamber 12. Wherein, the gas turbine vane 1 is connected to the gas turbine rotor blade 2 through a rim seal 3 .

[0034] and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com