Magnetically-levitated electric stir-fried stove

A magnetic levitation and frying stove technology, which is applied in the direction of utensils with integral electric heating devices, cooker brackets, kitchen utensils, etc., can solve the problems of lower energy utilization efficiency, inconvenient operation, and heavy pots, etc. Utilization rate, uniform and rapid heating, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

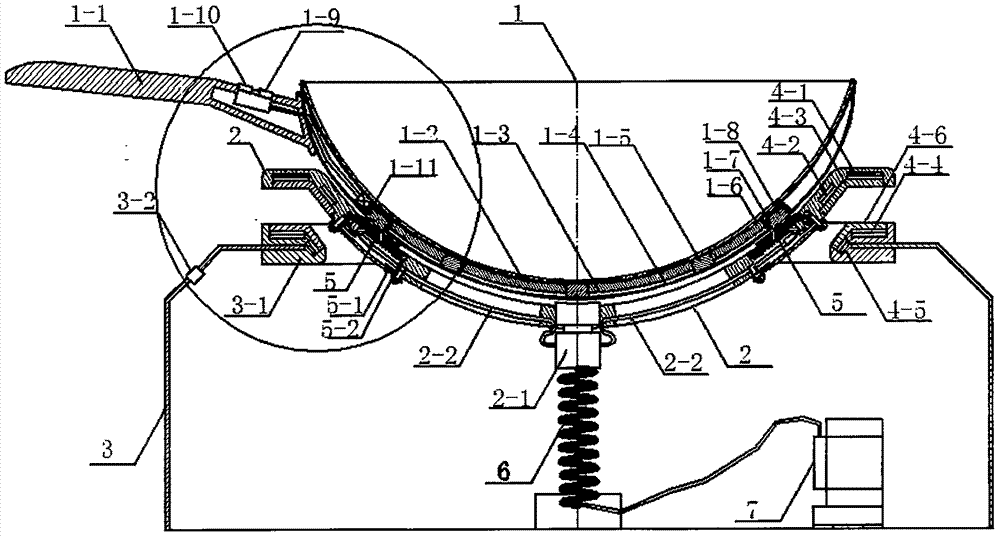

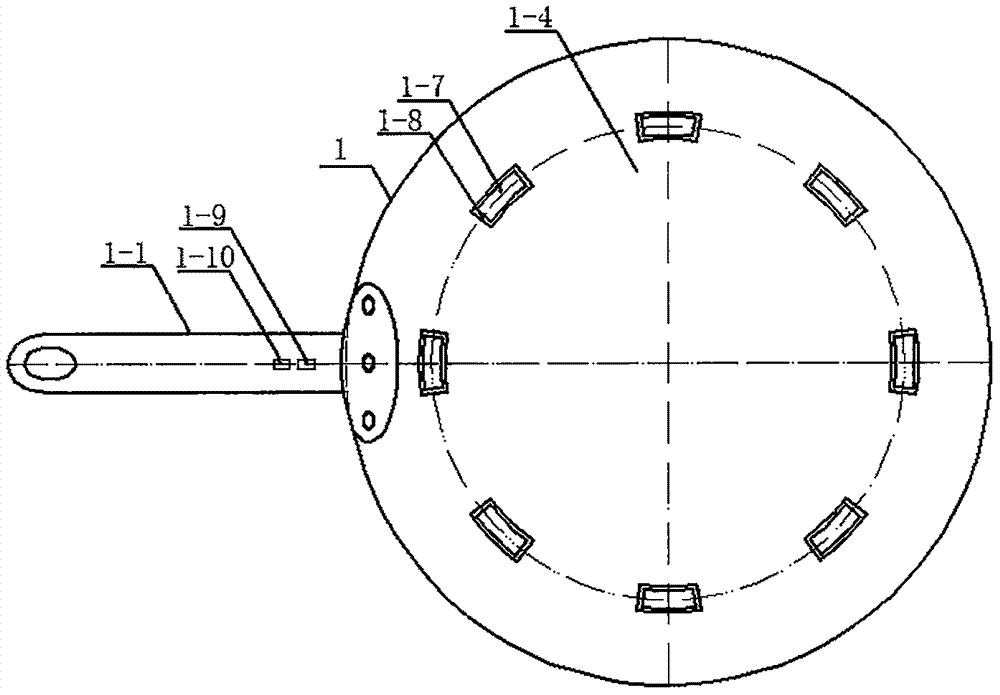

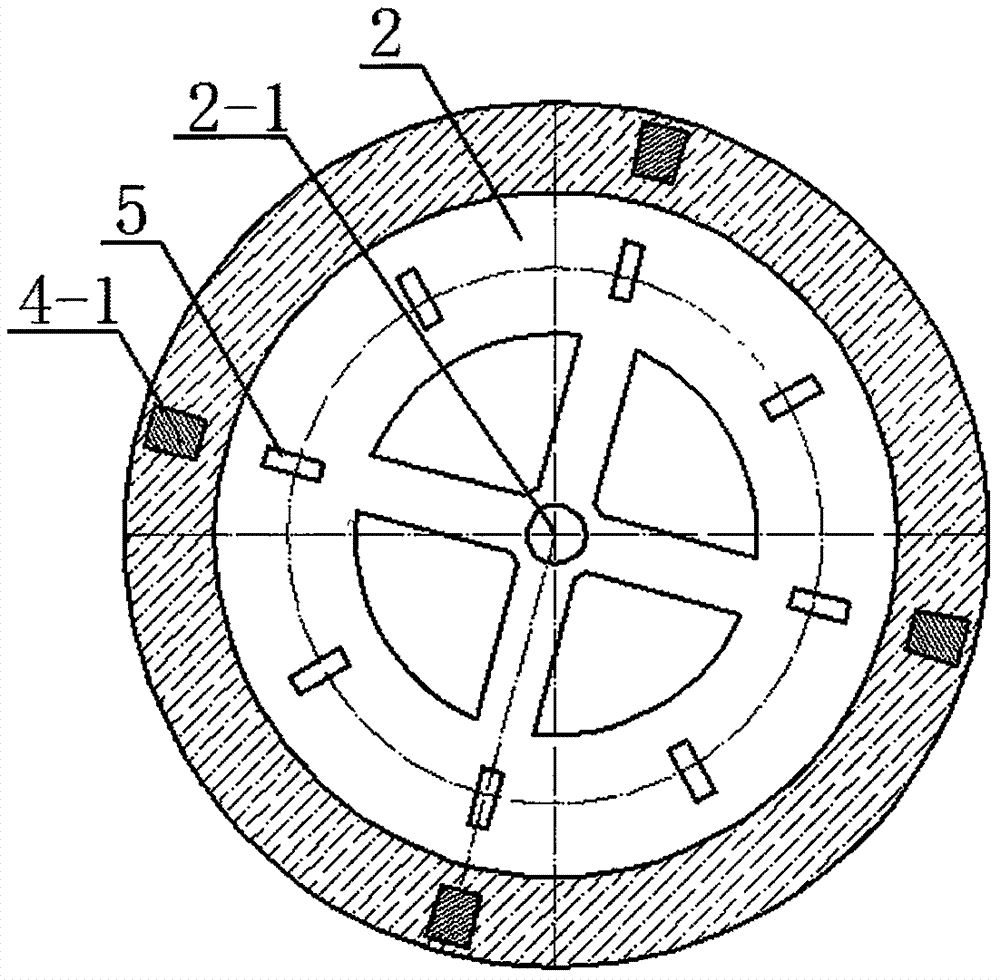

[0010] The present invention is further illustrated by means of examples shown in the accompanying drawings. Such as figure 1As shown, the technical solution adopted in the present invention is: the magnetic levitation electric frying range is composed of an electric frying pan (1), a pot support (2) and a cooking range base (3). The electric frying pan is seated in the pot support, and the pot support is seated on the magnetic levitation device between the pot support and the pot stove base, and the electric frying pan is connected to supply power through the shortcut electrodes arranged on the outer pot (1-4). It is characterized in that: the shortcut electrodes arranged on the outer pot (1-4) of the electric frying pan (1) are connected to the power source through the shortcut electrodes of the pot support (2). The electric frying pan is an electric heating integrated pot, and the electric frying pan is composed of a metal inner pot (1-2), an electric heating layer (1-3), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com